Tunnel grouting process in salt rock stratum

A technology for grouting and tunneling, which is applied in tunnels, tunnel linings, underground chambers, etc., and can solve problems such as grouting technology, inability to refer to grouting technology, and large differences in salt rock formation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The Laos section of the Friendship Tunnel of the China-Laos Railway ZLZQ-1 has a total length of 2425m, and has two work areas, the exit and the 3# inclined shaft. The construction started in March 2017. At present, the excavation length of the upper step in the export work area is 1100m, and the lining is 800m completed. The step in the 3# inclined shaft work area is excavated to DK0+890 in the long-distance direction, and the length is about 300mm. The working face is currently in a state of suspension; The steps are excavated in the direction of Xiaolijie to DK0+496.4, with a length of about 204m. In April 2018, after the 3# inclined shaft work area entered the hole, it was constructed in the direction of the large and small mileage. After May, it was found that the salt content of the surrounding rock continued to increase. On-site inspection found that the DK0+550~+890 section is a salt rock formation. The salt content gradually increased to DK0+550, and the highes...

Embodiment 2

[0039] The situation of the tunnel in this embodiment is the same as that in Embodiment 1.

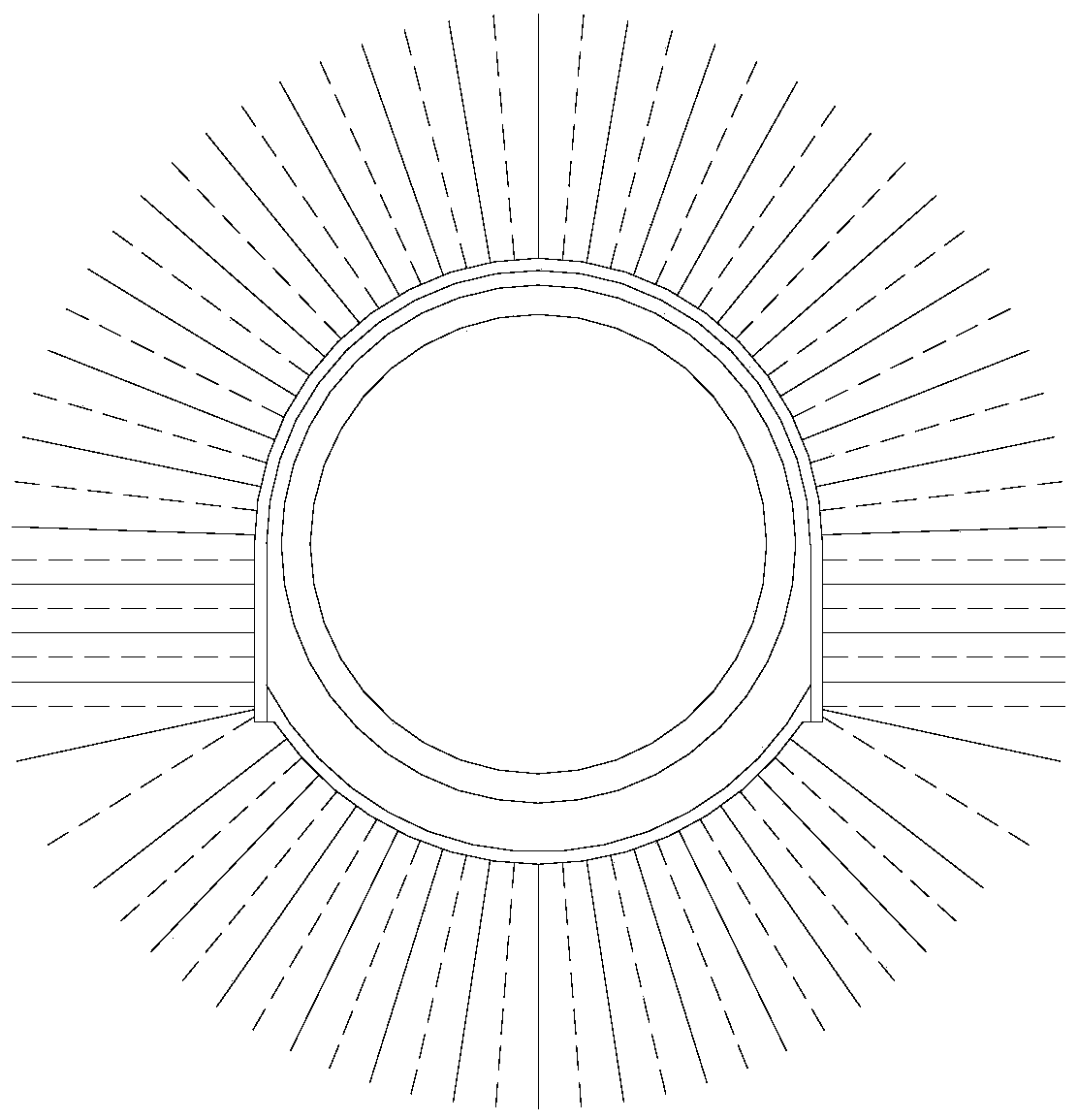

[0040] This embodiment provides a tunnel grouting process in salt rock formation, which is used for grouting and water plugging after excavation of DK0+000~DK0+356 and DK0+850~DK1+530. The details are as follows: (1) Grout hole arrangement: grouting holes are drilled around the tunnel, and anti-corrosion grouting pipes are installed; (2) grout configuration: common cement slurry and superfine cement slurry are prepared with brine, of which the water-cement ratio of normal cement slurry is 0.8, and the superfine cement slurry The water-cement ratio of cement is 0.6, and the concentration of brine is 10-21%; (3) Grouting: When the groundwater volume is strand-like water or above, pour ordinary cement slurry and superfine cement slurry in sequence; When dripping water and below, pour ultra-fine cement slurry.

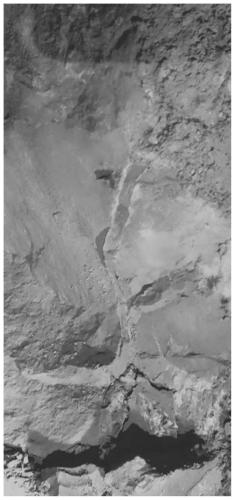

[0041] figure 2 It is the effect diagram of water blocking when the groundw...

Embodiment 3

[0043] The situation of the tunnel in this embodiment is the same as that in Embodiment 1.

[0044] This embodiment provides a tunnel grouting process in salt rock formation, which is used for grouting and water plugging after excavation of DK0+000~DK0+356 and DK0+850~DK1+530. The details are as follows: (1) Layout of grouting holes: grouting holes are drilled around the tunnel, and anti-corrosion grouting pipes are installed; (2) grout configuration: common cement slurry and superfine cement slurry are prepared with brine, of which the water-cement ratio of normal cement slurry is 0.6, and superfine cement slurry The water-cement ratio of cement is 0.5, and the concentration of brine is 10-21%; (3) Grouting: When the groundwater volume is strand-like water and above, pour ordinary cement slurry and superfine cement slurry in sequence; When dripping water and below, pour ultra-fine cement slurry.

[0045] image 3 It is the effect diagram of water blocking when the groundwat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com