A treatment method for industrial floor construction joints

A technology for industrial flooring and treatment methods, which is applied in construction, building maintenance, building construction, etc., and can solve problems such as the reduction of concrete strength and the inability to treat construction joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

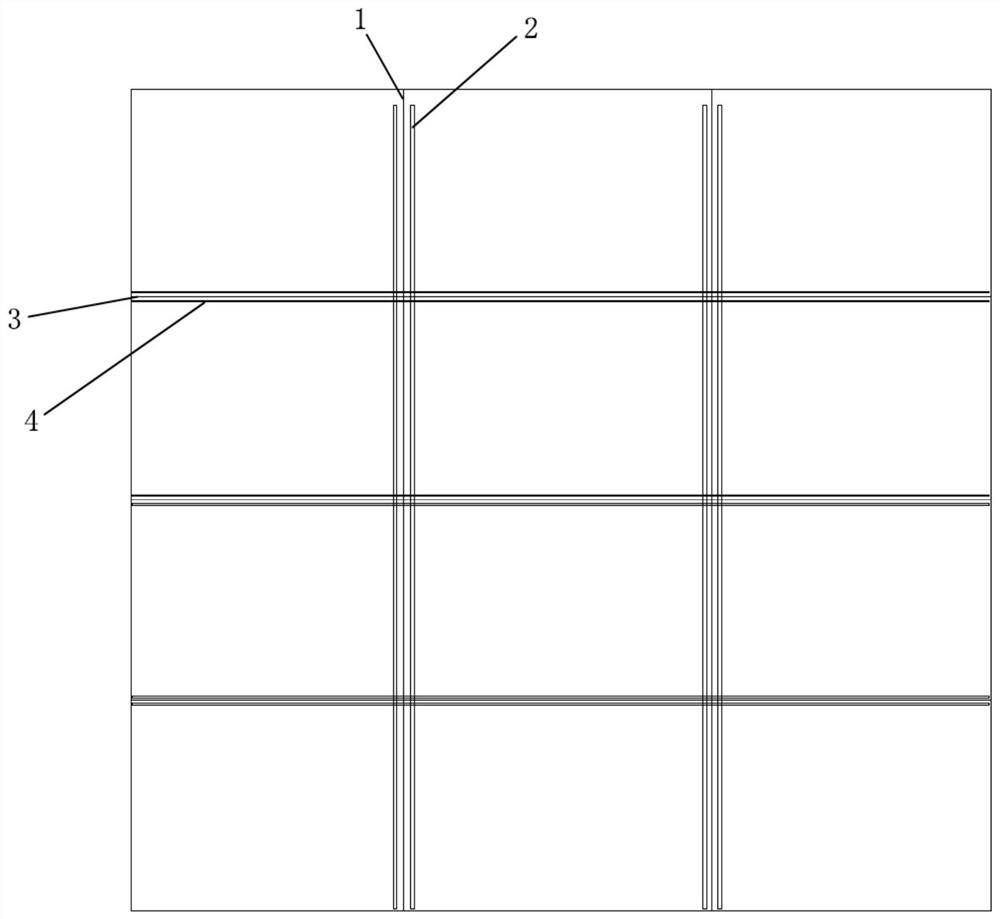

[0025] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0026] Such as figure 1 Shown, a kind of industrial floor construction joint treatment method comprises the following steps:

[0027] S1. Grinding the surface of the industrial floor;

[0028] S2. Perform shot blasting and riveting operations on the surface of the industrial floor;

[0029] S3. Perform slotting operations on both sides of the construction joint 1 to form two main riveting grooves 2 parallel to the construction joint 1;

[0030] S4. Pour the anti-corrosion resin paint into the main riveting groove 2 and the construction joint 1 until the main riveting groove 2 and the construction joint 1 are completely filled with the anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com