Main tower lower cross beam support pre-pressing device and pre-pressing method thereof

A beam support and main tower technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of complex operation process, inaccurate preload data, and inability to guarantee the direction of force application, and achieve simple application process, Good adjustment effect and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

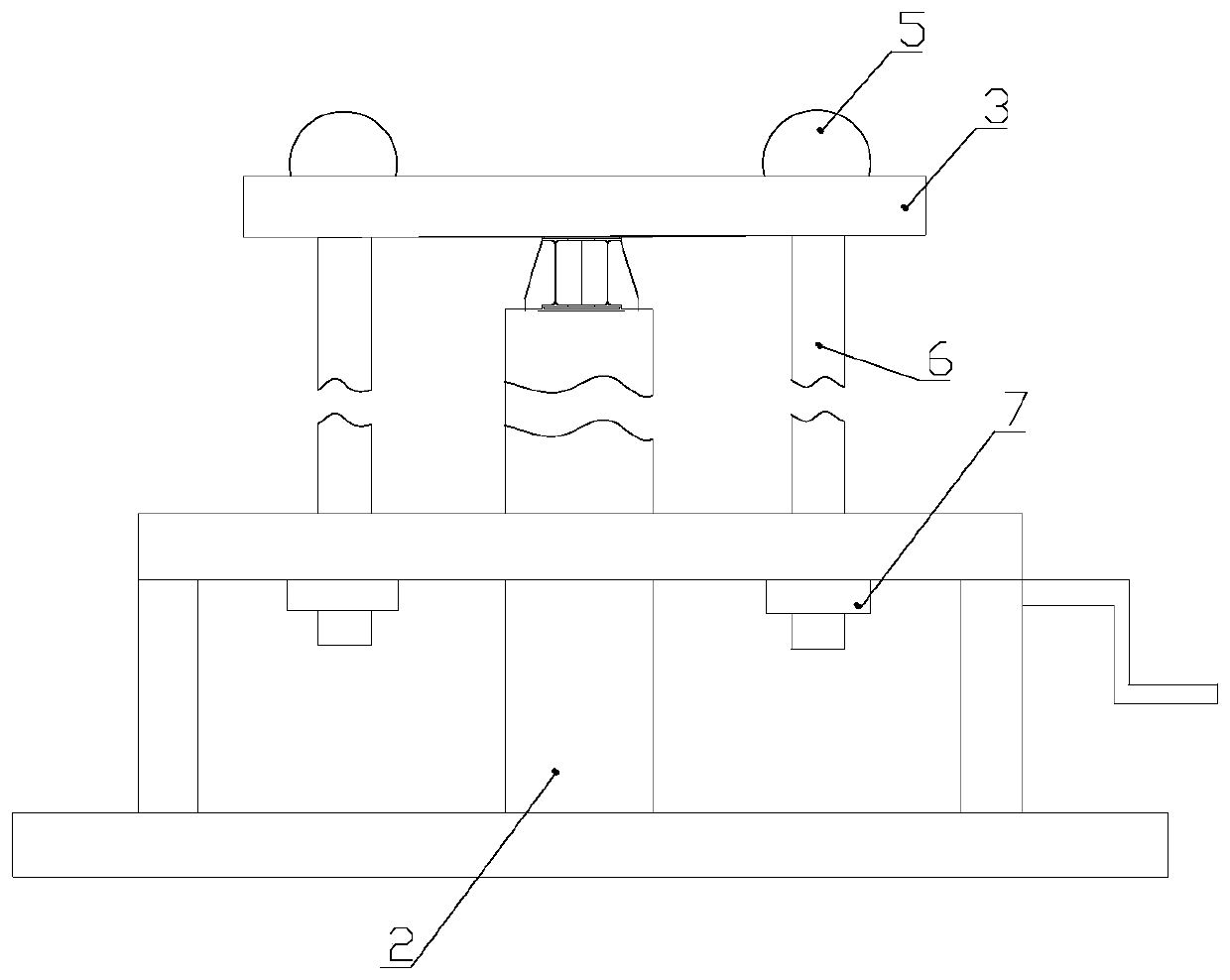

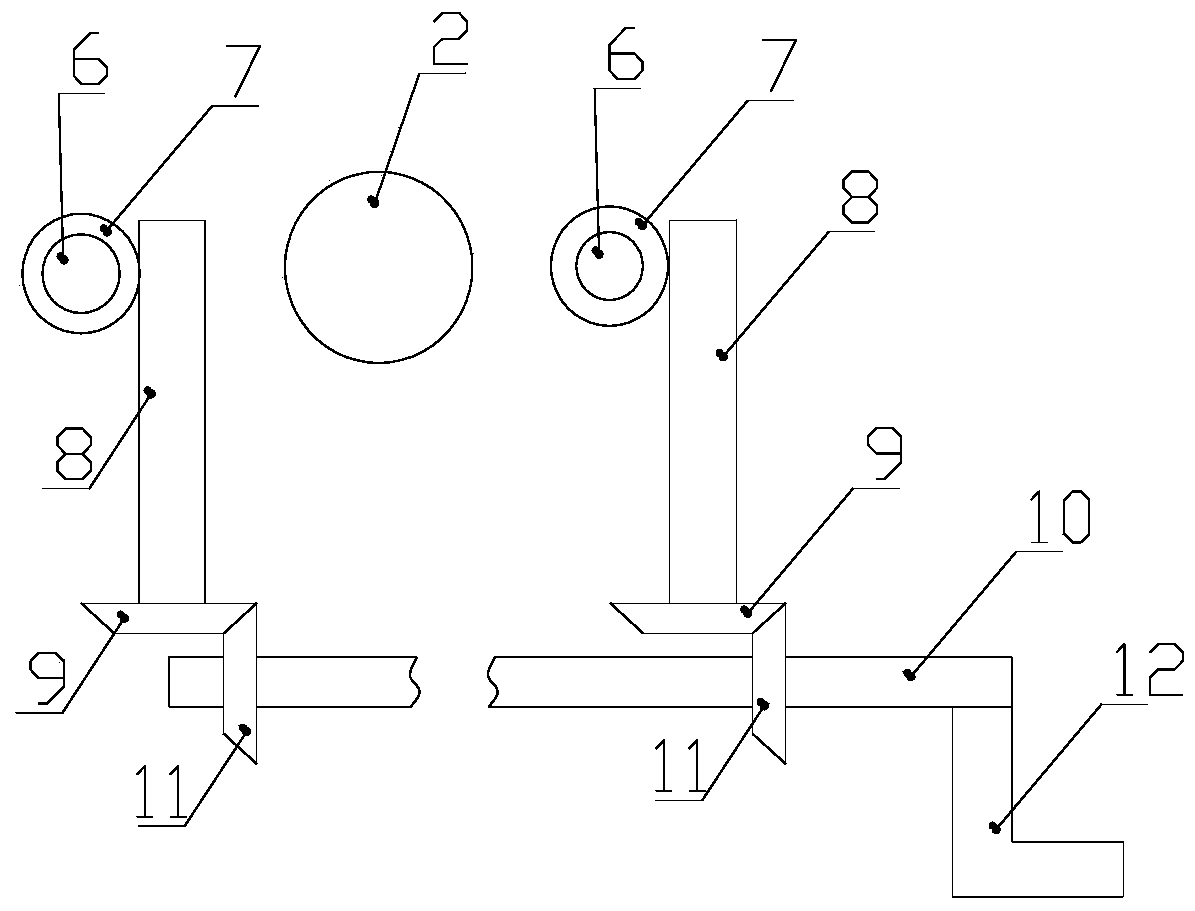

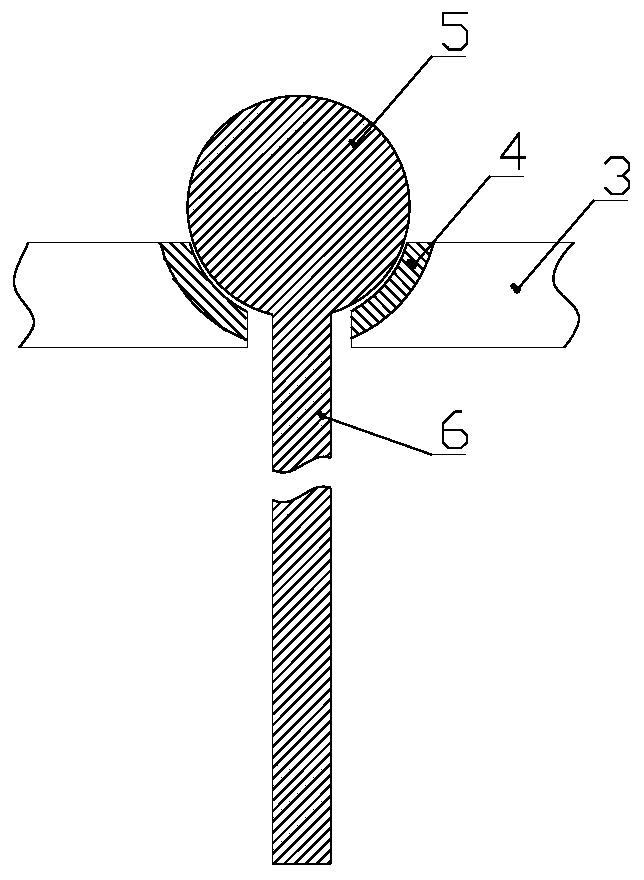

[0036] see figure 1 and figure 2 , the main tower lower beam support preloading device of the present embodiment comprises column 2, beam 3, tensioning mechanism, transmission mechanism, rotation drive mechanism and bottom support frame, and tensioning mechanism has two, is symmetrically arranged on column 2 respectively Outer side, column 2 has 5, is arranged on the below of beam 3 respectively to support beam 3, is provided with balance clamp block, tension column 6 and tension column limit piece 7 on the tension mechanism, is provided with on beam 3 Mounting hole, the upper part of the mounting hole is provided with a balance clamp installation groove, the balance clamp is fixed in the balance clamp installation groove, the size of the balance clamp is larger than the aperture of the installation hole, the top of the tension column 6 passes through the installation hole and the balance clamp block connection, the bottom of the tension column is connected with the tension ...

Embodiment 2

[0040] The preloading device for the lower beam support of the main tower in this embodiment includes a column 2, a beam 3, a tensioning mechanism, a transmission mechanism, a rotary drive mechanism and a bottom support frame. There are three tensioning mechanisms, which are symmetrically arranged on the outside of the column 2 , there are 7 upright columns 2, which are respectively arranged under the beam 3 to support the beam 3. The tensioning mechanism is provided with a balance clamp, a tensioning column 6 and a tensioning column limiter, and a mounting hole is arranged on the beam 3. , the upper part of the mounting hole is provided with a balance clamp installation groove, the balance clamp is fixed in the balance clamp installation groove, the size of the balance clamp is larger than the aperture of the installation hole, and the top of the tension column 6 passes through the installation hole and is connected with the balance clamp , the bottom of the tensioning column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com