Waterproof yarn processing technology

A processing technology and waterproof treatment technology, applied in the textile field, can solve the problems affecting the quality of waterproof yarn, and the waterproof agent and dye are not easily attached to the surface of the yarn, so as to improve the waterproof effect, improve the anti-insect effect, and improve the oil removal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

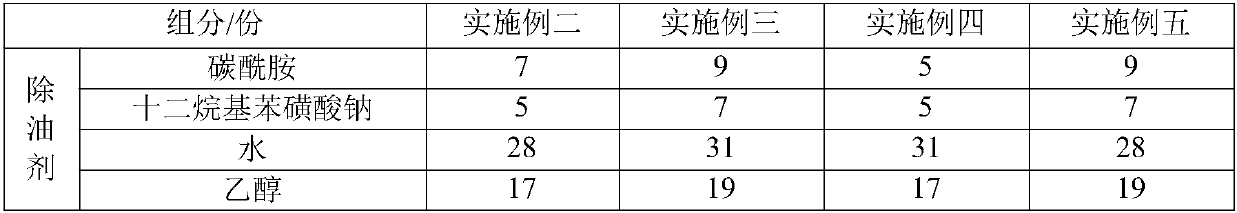

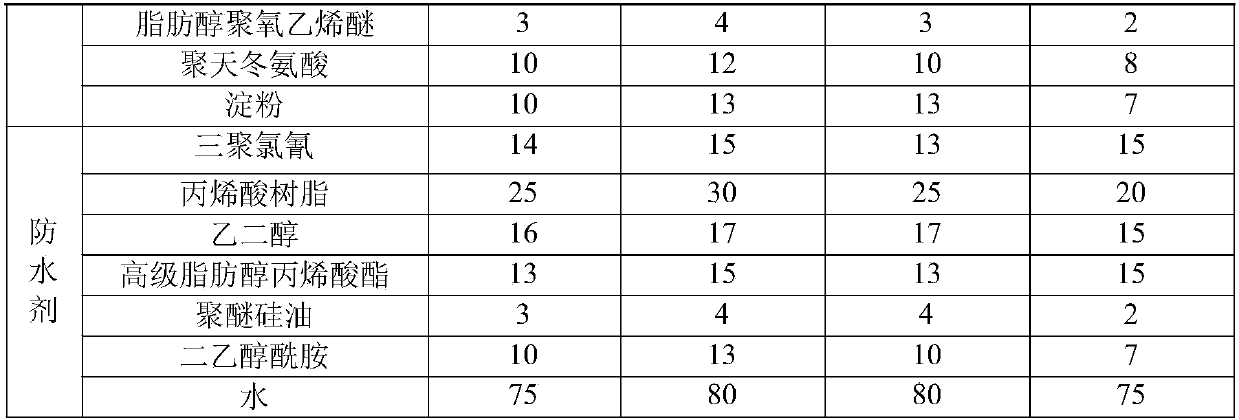

Examples

Embodiment 1

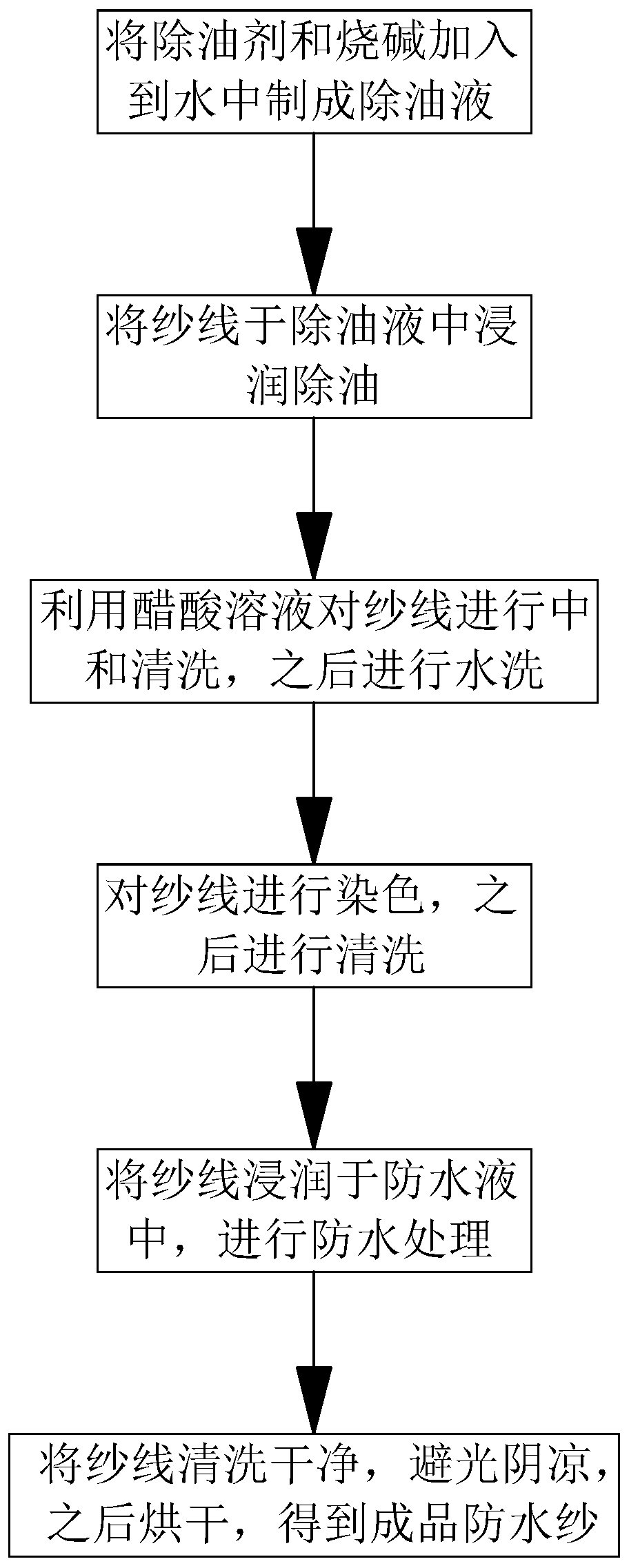

[0039] A kind of processing technology of waterproof yarn, with reference to attached figure 1 shown, including the following steps:

[0040] Step 1: Add 1Kg degreaser and 500g caustic soda to 1m 3 Mix in clear water at a speed of 500rpm to obtain a degreasing liquid;

[0041] Step 2: Heat the degreasing liquid to 90°C, soak the yarn into the degreasing liquid, and keep it warm for 30 minutes;

[0042] Step 3: Use an acetic acid solution with a concentration of 0.2 g / L to neutralize and wash the degreased yarn for 5 minutes, and then wash it with water for 3 minutes;

[0043] Step 4: put the yarn into the dyeing vat, and add 55% clear water of the volume of the dyeing vat, add the leveling agent GS and the dye HFRL violet at a ratio of 1:2 to the dyeing vat in turn, to obtain a dyeing solution with a concentration of 5 wt% of the dye HFRL violet, Dyeing is carried out in sequence (①heat up to 80°C at 1.5°C / min; ②raise to 135°C at 1.2°C / min and keep warm for 40 minutes; ③dir...

Embodiment 6

[0061] The difference between this example and Example 5 is that the starch of the present application is soaked in 3% hydrogen peroxide for 1 hour to obtain oxidized starch.

Embodiment 7

[0063] The difference between the present embodiment and the fifth embodiment is only that the cyanuric chloride of the present application is modified by palmityl secondary amine.

[0064] The concrete steps are as follows: the first step: mix 0.1mol cyanuric chloride, 0.5mol anhydrous K 2 CO 3 , 0.25mol of palmityl secondary amines were added successively in a 250mL three-necked flask, protected by nitrogen, left to stand for 0.5h under an ice-water bath, injected with 200mL of dry THF and dry dioxane [V(THF):V(dioxane)= 1:4], reacted in an ice-water bath and at room temperature for 4 h respectively, and then refluxed the reaction, removed the solvent under reduced pressure, washed with water until neutral, and separated by column chromatography [eluent: V (ethyl acetate): V (petroleum ether)=1:200], to obtain a white solid powder;

[0065] The second step: 0.5mol anhydrous K 2 CO 3 , 50mL 1,6-hexamethylenediamine and 150mL dioxane were sequentially added to the white so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com