Reaction and separation integrated countercurrent hydrogenation reaction process

A technology for hydrogenation reaction and hydrogenation reactor, which is applied in the fields of hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of low product quality and low hydrogenation capacity, achieve high hydrogen purity, and promote hydrogenation. Cracking reaction, height reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

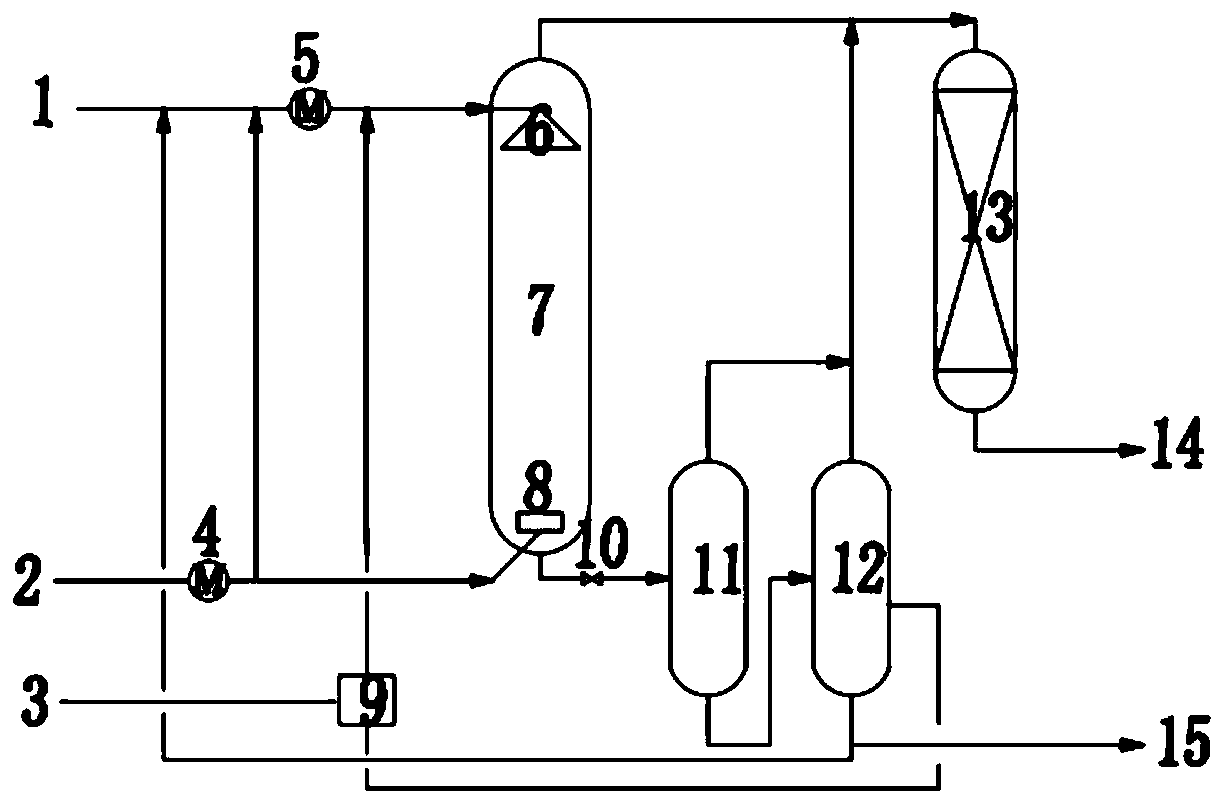

[0037] In the heavy and inferior oil hydrocracking unit, the homogeneous oil-soluble catalyst and the second-line oil from the atmospheric and vacuum unit are mixed at a ratio of 99:1 in the mixer 9 to prepare catalyst slurry; vacuum residue 1 and part of hydrogen 2 (Hydrogen mixing) mixed at a volume ratio of 1:9, heated to 420°C through the raw material heating furnace 5, and then mixed with the slurry of the catalyst 3 at a liquid volume ratio of 99:1 to form a mixed feed, which is fed by the reactor The upper part enters the upper part of the hydrocracking reactor 7 through the shower 6; the other part of the hydrogen 2 (reactive hydrogen) is heated to 420°C by the hydrogen heating furnace 4, and then distributed from the bottom of the reactor by the hydrogen distributor 8 to enter the hydrogenation process. The bottom of the cracking reactor 7; the reaction raw materials, the catalyst and the hydrogen entering the bottom are in countercurrent contact in the hydrocracking r...

Embodiment 2

[0039] In the coal direct liquefaction unit, the heterogeneous solid catalyst and the second-line oil from the atmospheric and vacuum unit are mixed at a ratio of 19:1 in the mixer 9 to prepare a catalyst slurry; the coal concentration is 40% oil prepared by coal and solvent oil Coal slurry 1 and part of hydrogen 2 (mixed hydrogen) are mixed at a volume ratio of 1:7, and after being heated to 460°C in the raw material heating furnace 5, they are mixed with the slurry of catalyst 3 at a liquid volume ratio of 49:1 to form a mixed feed , the mixed feed enters the upper part of the hydrocracking reactor 7 from the upper part of the reactor through the sprayer 6; another part of the hydrogen 2 (reactive hydrogen) is heated to 460 ° C by the hydrogen heating furnace Distributor 8 distributes into the bottom of hydrocracking reactor 7; the reaction raw materials, catalyst and the hydrogen entering from the bottom are in countercurrent contact in the hydrocracking reactor for heat and...

Embodiment 3

[0041] In the kerosene co-refining unit, the heterogeneous solid-loaded catalyst and the second-line oil from the atmospheric and vacuum unit are mixed at a ratio of 9:1 in the mixer 9 to prepare a catalyst slurry; the coal concentration prepared by coal and catalytic cracking oil slurry 40% oil-coal slurry 1 and part of hydrogen 2 (mixed hydrogen) are mixed at a volume ratio of 1:7, and after the raw material heating furnace 5 is heated to 470°C, they are mixed with the catalyst 3 slurry at a liquid volume ratio of 19:1 , forming a mixed feed, the mixed feed enters the upper part of the hydrocracking reactor 7 from the upper part of the reactor through the shower 6; another part of the hydrogen 2 (reactive hydrogen) is heated to 470 ° C by the hydrogen heating furnace 4, and then The bottom of the reactor is distributed into the bottom of the hydrocracking reactor 7 by the hydrogen distributor 8; the reaction raw materials, the catalyst and the hydrogen entering the bottom are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com