Solid-solid phase change material as well as preparation method and application thereof

A solid-solid phase change material, n-tetradecane technology, applied in applications, heat exchange materials, chemical instruments and methods, etc., can solve the problems of ice box deformation, instability, volatile, etc. shape stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, solid-solid phase change material and its preparation

[0044] Weigh 855g of n-tetradecane and 45g of n-tridecane, pour them into the reactor and heat to 60°C, weigh 100g of ultrafine 52° semi-refined paraffin wax and add it to the reactor, turn on the stirrer, and continue to heat up to 80°C. Stir continuously, observe that the superfine 52° semi-refined paraffin is completely dissolved, cool down to 60°C, and let stand for 30 minutes. Cool to room temperature (25°C) to obtain a solid phase change material, also known as a solid phase change cool storage agent.

[0045] Cool the temperature to 60°C and let it stand for 30 minutes during the above process of preparing the solid-solid phase change material, and then pour it into a corresponding container (such as a plastic box, a plastic hollow plate or a plastic bag) to obtain a cold storage device.

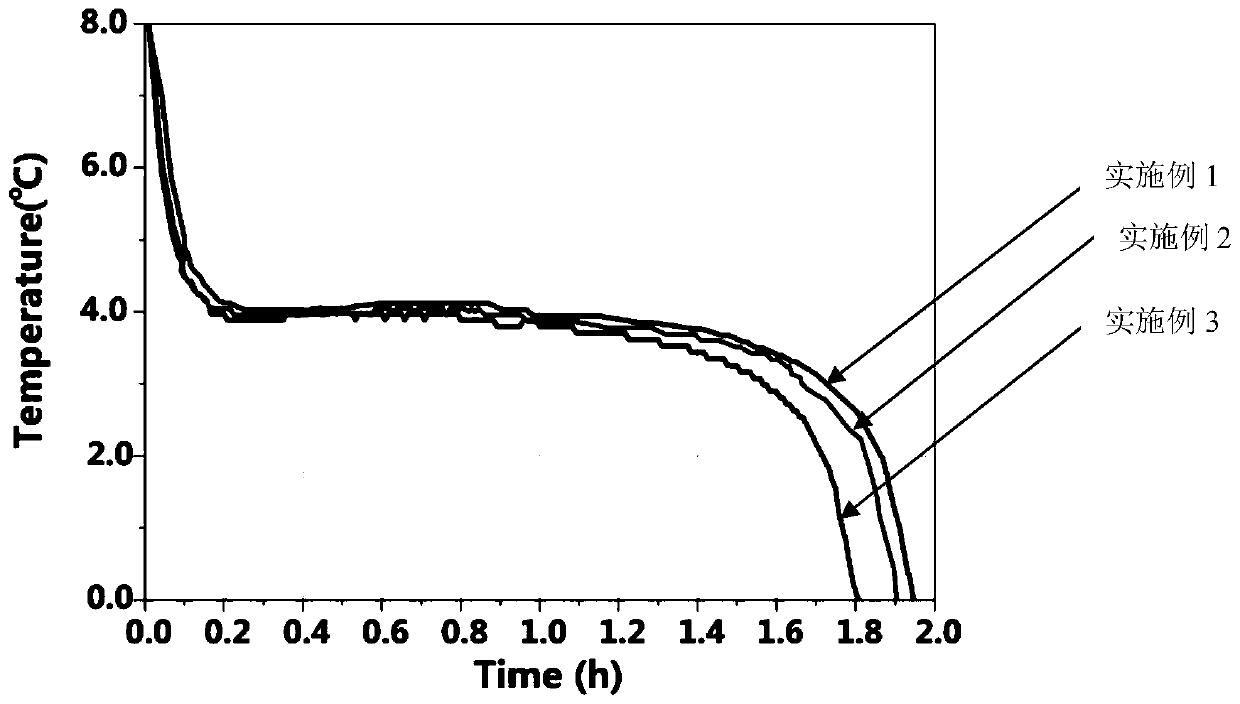

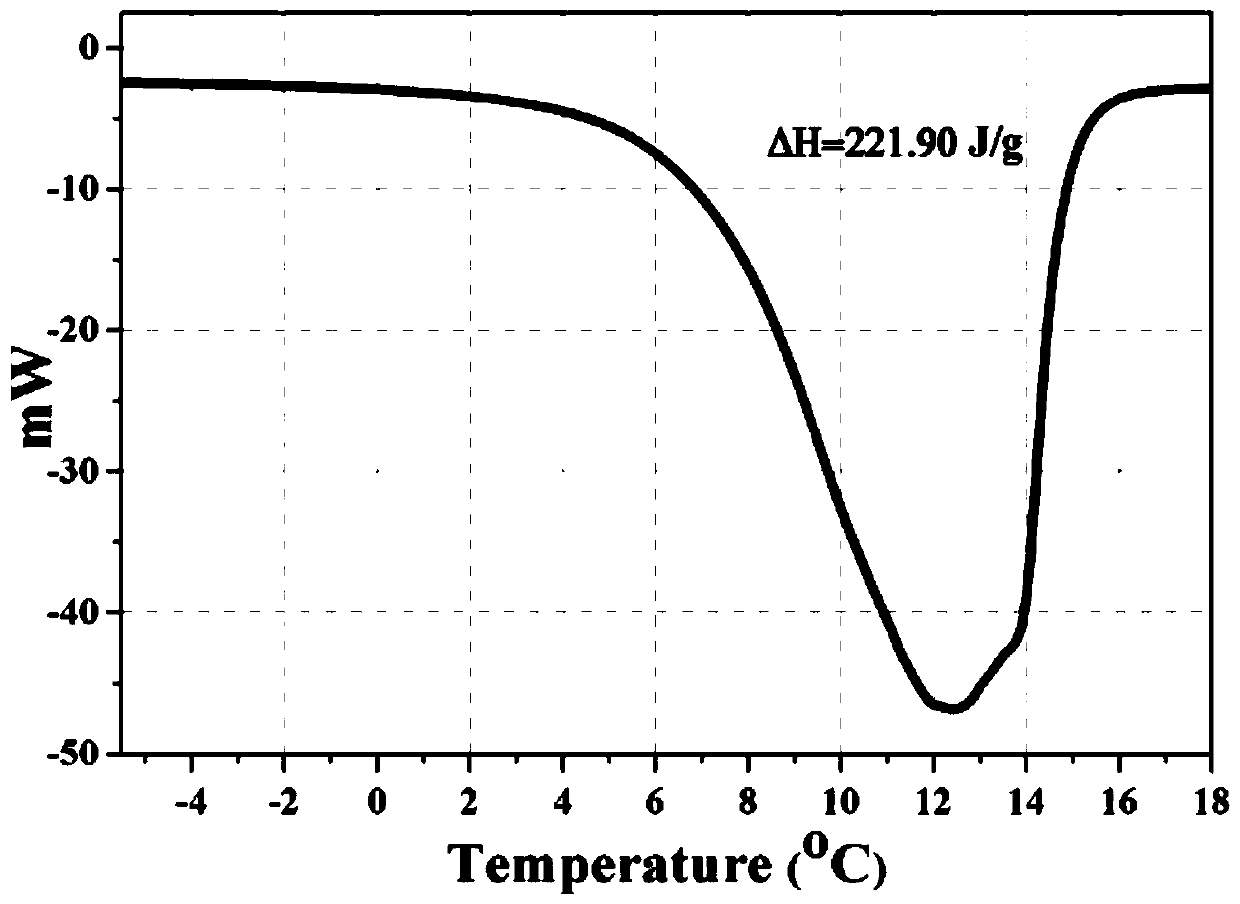

[0046] The freeze-thaw curve of the solid phase change material obtained in this example is as follows f...

Embodiment 2

[0048] Embodiment 2, solid-solid phase change material and preparation thereof

[0049] Weigh 831.6g of n-tetradecane and 48.4g of n-tridecane, pour them into the reactor and heat to 60°C, weigh 120g of ultra-fine 52° semi-refined paraffin and add them to the reactor, turn on the stirrer, and continue to heat up to 80°C ℃, keep stirring, observe that the ultra-fine 52° semi-refined paraffin is completely dissolved, cool down to 60 ℃, and let it stand for 30 minutes. Cool to room temperature (25°C) to obtain a solid phase-change cool storage agent.

[0050] Cool the temperature to 60°C and let it stand for 30 minutes during the above process of preparing the solid-solid phase change material, and then pour it into a corresponding container (such as a plastic box, a plastic hollow plate or a plastic bag) to obtain a cold storage device.

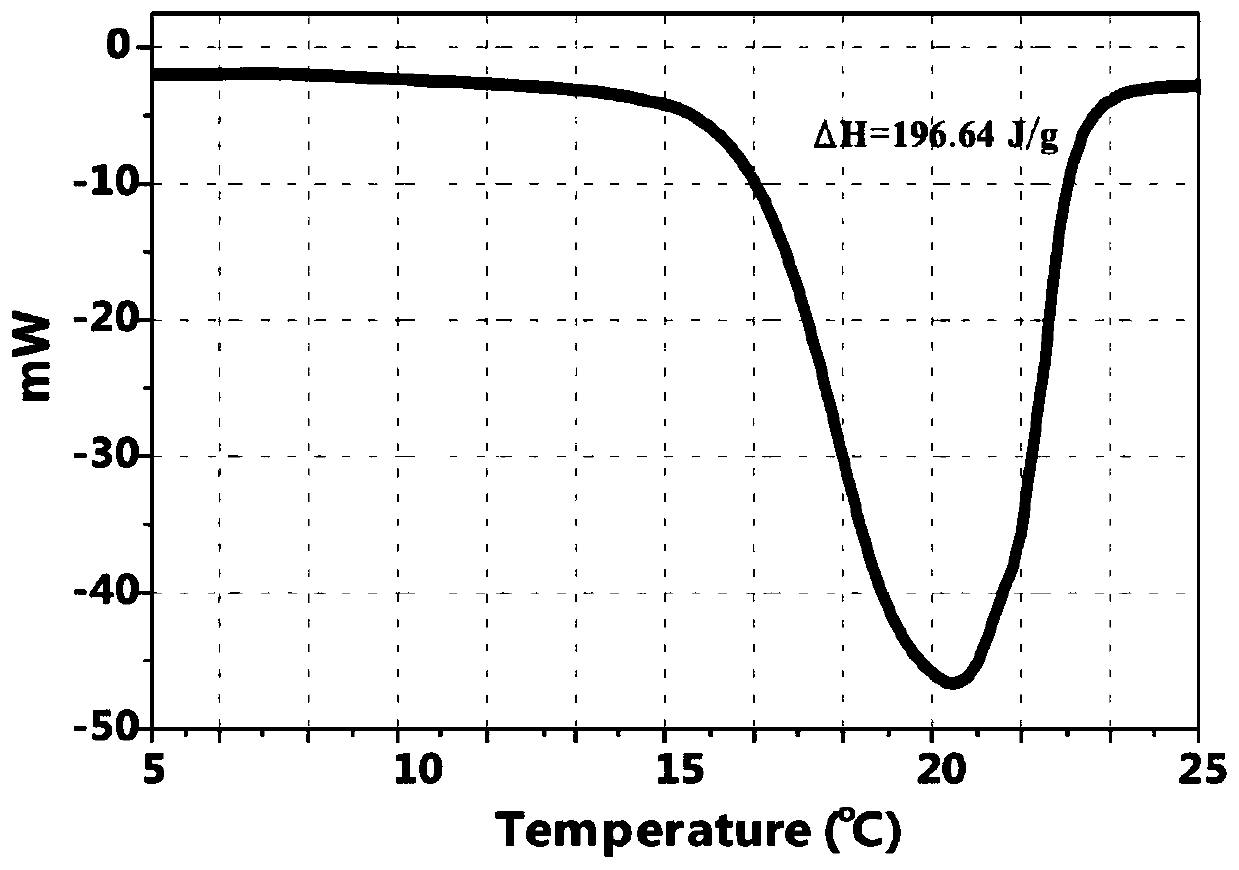

[0051] The freeze-thaw curve of the solid phase change material obtained in this example is as follows figure 1 As shown, the obtained solid...

Embodiment 3

[0053] Embodiment 3, solid-solid phase change material and preparation thereof

[0054] Weigh 827.2g of n-tetradecane and 52.8g of n-tridecane, pour them into the reactor and heat to 60°C, weigh 120g of ultra-fine 52° semi-refined paraffin and add them to the reactor, turn on the stirrer, and continue to heat up to 80°C ℃, keep stirring, observe that the ultra-fine 52° semi-refined paraffin is completely dissolved, cool down to 60 ℃, and let it stand for 30 minutes. Cool to room temperature (25°C) to obtain a solid phase-change cool storage agent.

[0055] Cool the temperature to 60°C and let it stand for 30 minutes during the above process of preparing the solid-solid phase change material, and then pour it into a corresponding container (such as a plastic box, a plastic hollow plate or a plastic bag) to obtain a cold storage device.

[0056] The freeze-thaw curve of the solid phase change material obtained in this example is as follows figure 1 As shown, the obtained solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com