Glass composition

A technology of glass composition and mole percentage, which is applied in the field of glass composition and can solve the problems of glass substrate dissolution and loss

Active Publication Date: 2020-08-25

CDGM OPTICAL GLASS +1

View PDF33 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] During the chip manufacturing process, there will be many acid and alkali cleanings, which requires the glass substrate material to have excellent water resistance, acid resistance and alkali resistance, otherwise the glass substrate will dissolve into the process solution, causing great losses

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

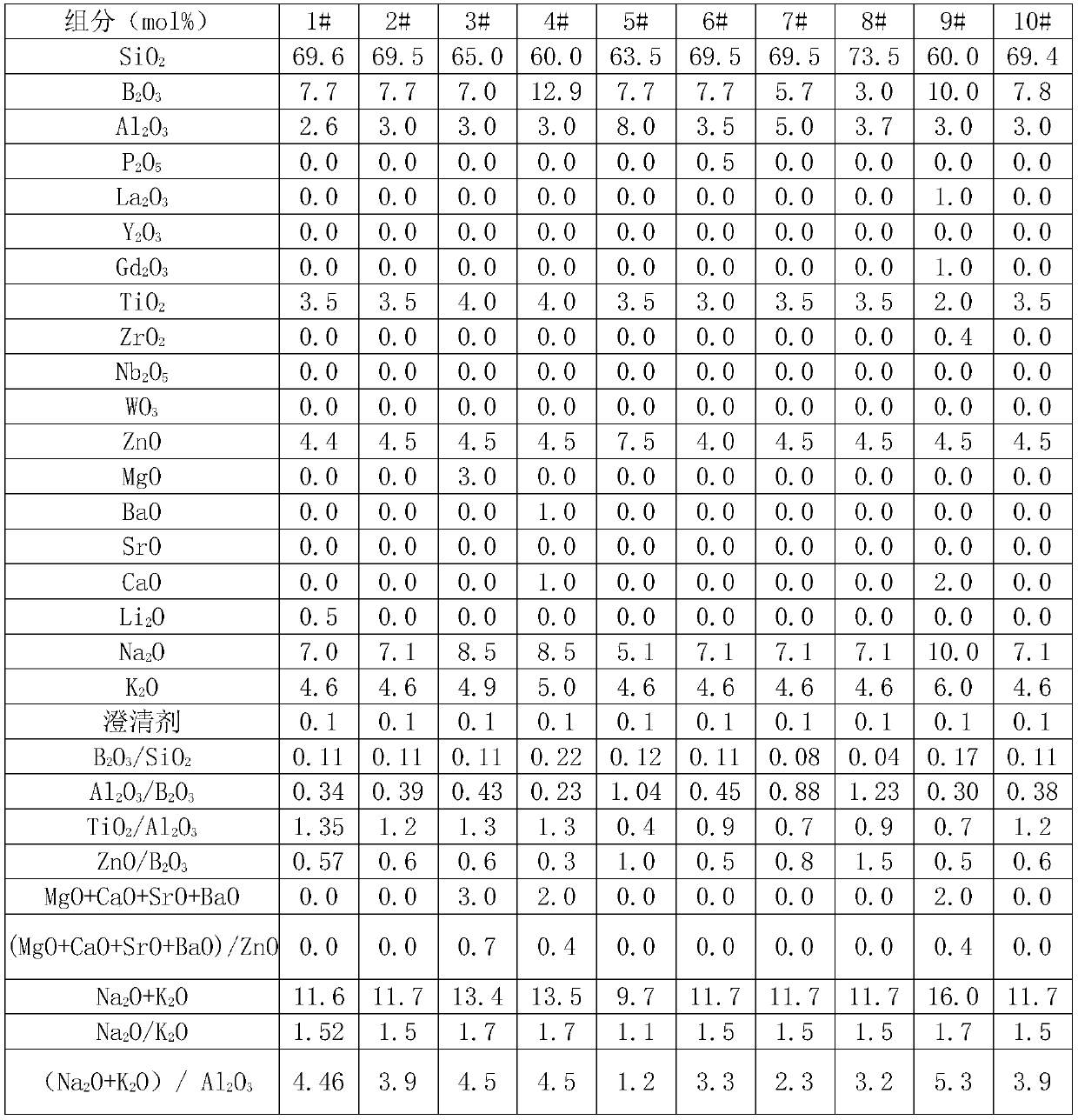

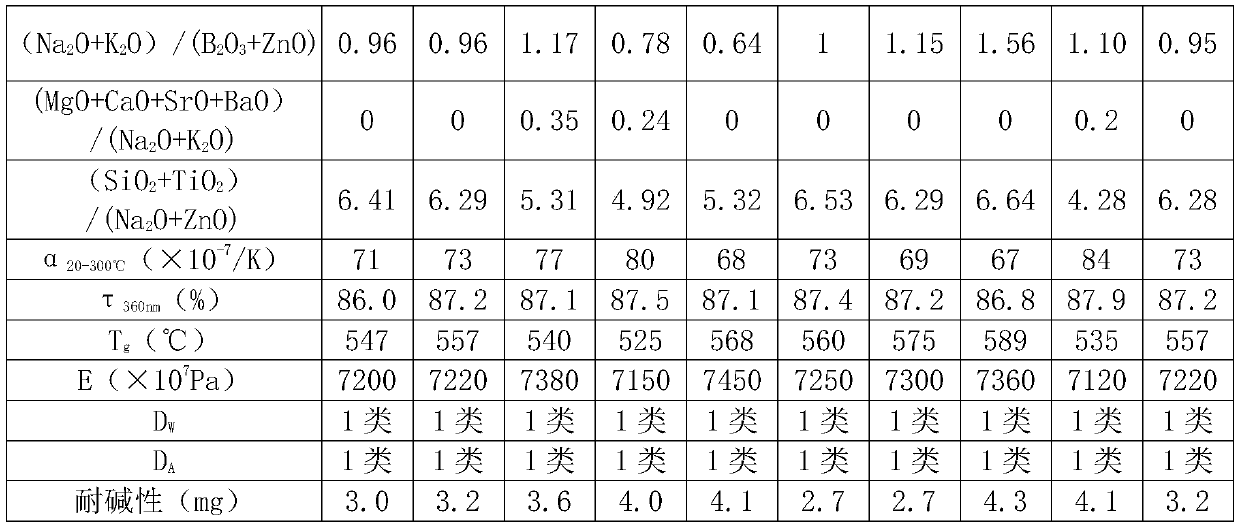

Embodiment 1~20

[0120] In this example, the glass composition having the composition shown in Table 1-Table 2 was obtained by adopting the manufacturing method of the above-mentioned glass composition. In addition, the properties of each glass were measured by the test method described in the present invention, and the measurement results are shown in Tables 1 to 2.

[0121] Table 1

[0122]

[0123]

[0124] Table 2

[0125]

[0126]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a glass composition. The glass composition comprises the following components in percentage by mole: 55 to 80% of SiO2, 2 to 15% of B2O3, 0.5 to 10% of TiO2, 0.5 to 12% of ZnO,0 to 10% of Al2O3, 1 to 15% of Na2O and 1-12% of K2O. Through reasonable component design, the obtained glass composition has a proper thermal expansion coefficient, high ultraviolet light transmittance and excellent water resistance, acid resistance and alkali resistance, meets the requirements of large-caliber high-quality processing, and is suitable for the fields of semiconductor manufacturingand the like.

Description

technical field [0001] The invention relates to a glass composition, in particular to a glass composition which can be used in the field of semiconductor manufacturing. Background technique [0002] In the field of semiconductor manufacturing, materials such as metal, ceramics, and single crystal silicon are usually used as the substrate of the wafer during the manufacturing process to prevent the deformation of the wafer during lithography, cleaning, packaging and other processes. Although metal, ceramic, and single crystal silicon substrate materials have good mechanical strength and acid and alkali corrosion resistance, because the above substrate materials are opaque, a heating stripping process is required in the substrate and wafer stripping process. If a light-transmissive glass composition is used as the fabrication substrate, then a photolift-off process can be used. Compared with the thermal stripping process, the optical stripping process can greatly reduce the p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C3/093C03C3/097C03C4/00C03C4/20

CPCC03C3/093C03C4/0085C03C4/20C03C3/097

Inventor 毛露路匡波刘振禹聂小兵范少华司合帅王华翟玉山

Owner CDGM OPTICAL GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com