Tool for surface treatment

A technology of surface treatment and tools, which is applied in the direction of manufacturing tools, metal processing equipment, grinding machine parts, etc., can solve the problems of product quality decline, shortened service life, and bristle density can not be adjusted, so as to improve the ability and realize the utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

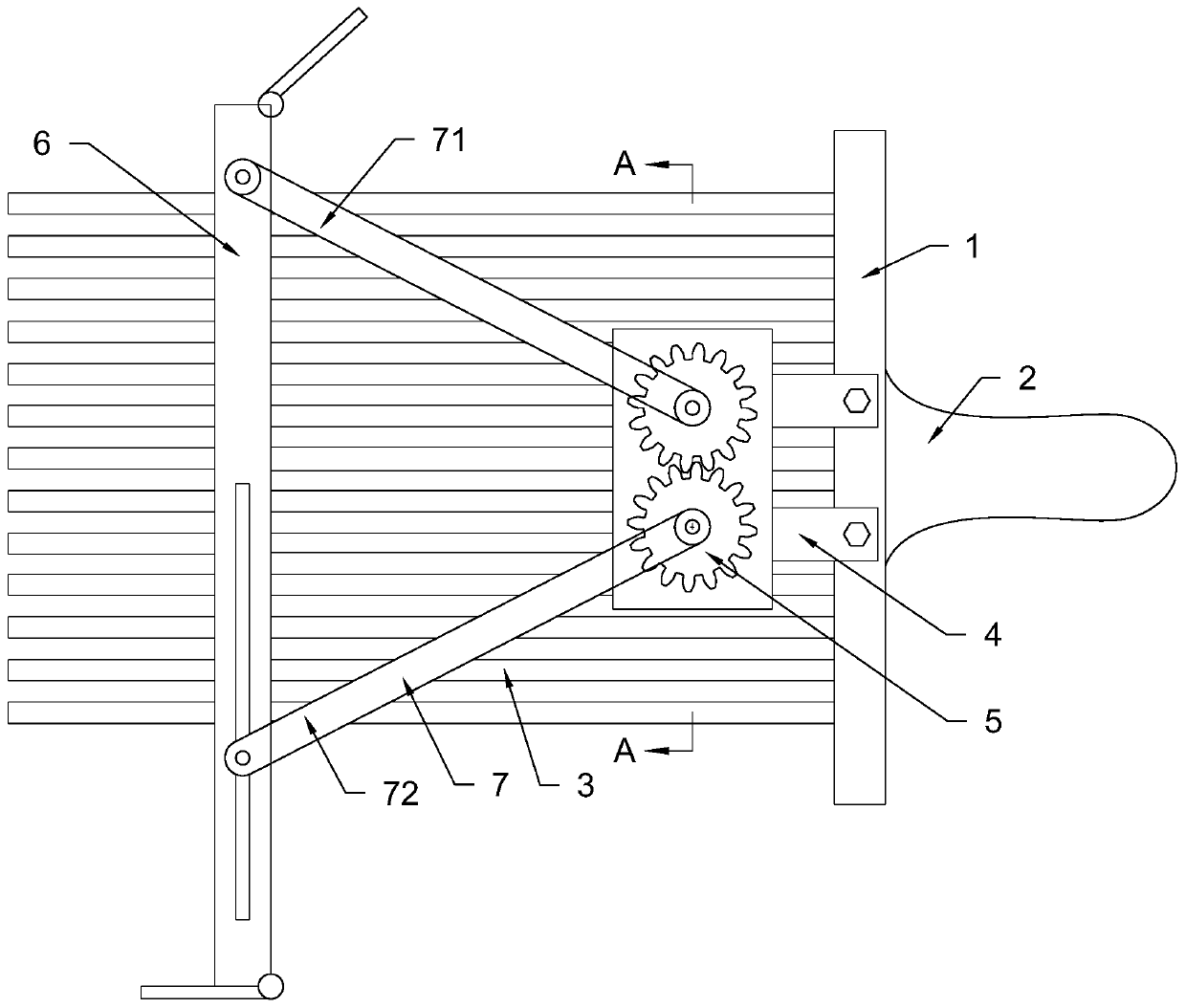

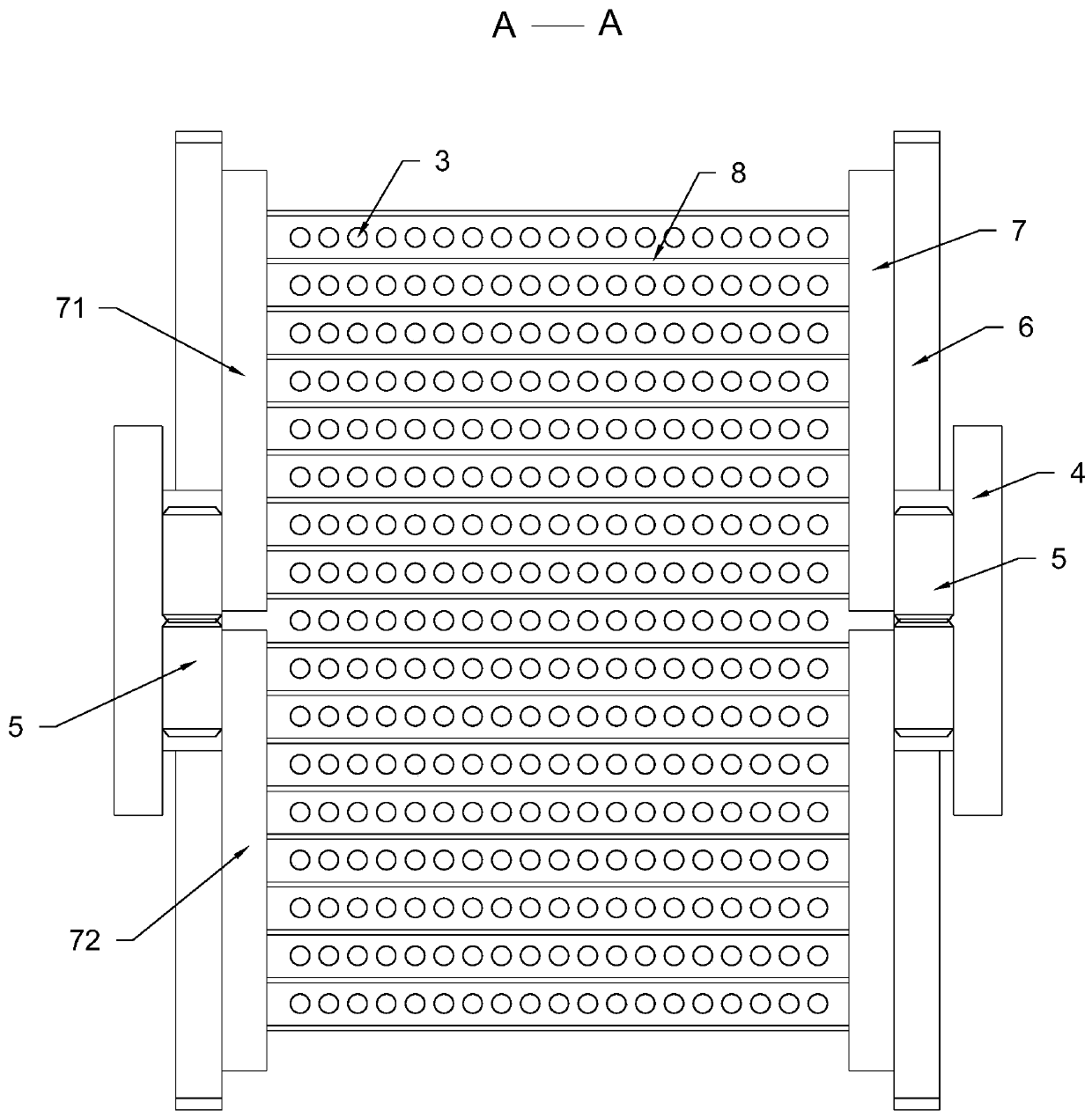

[0026] Such as figure 1 , 2 , a tool for surface treatment, including a base plate 1, a handle 2, bristles 3, a support frame 4, a gear set 5, a wire-eating adjustment plate 6, a connecting rod 7 and a round rod 8.

[0027] The cross-section of the substrate 1 is rectangular, and the substrate 1 is provided with a shaft hole; the bristles 3 are evenly arranged on the bottom surface of the substrate 1, and the material of the bristles 3 is steel wire; the handle 2 is fixed on the bottom surface of the substrate 1. Top; the number of the support frame 4 is two, the support frame 4 is symmetrically installed on the two sides of the base plate 1, and the support frame 4 and the base plate 1 are connected by bolts; the gear set 5 includes two There are two gears and these two gears mesh with each other. There are two gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com