Automatic processing system for building decoration garbage and working method thereof

A technology for decoration and disposal system, applied in construction waste recovery, recycling technology, solid waste removal, etc., can solve the problems of limited primary processing capacity, no better than domestic waste, and easily damaged equipment, etc., and achieves a simple working principle Easy to operate, ensure smooth operation, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

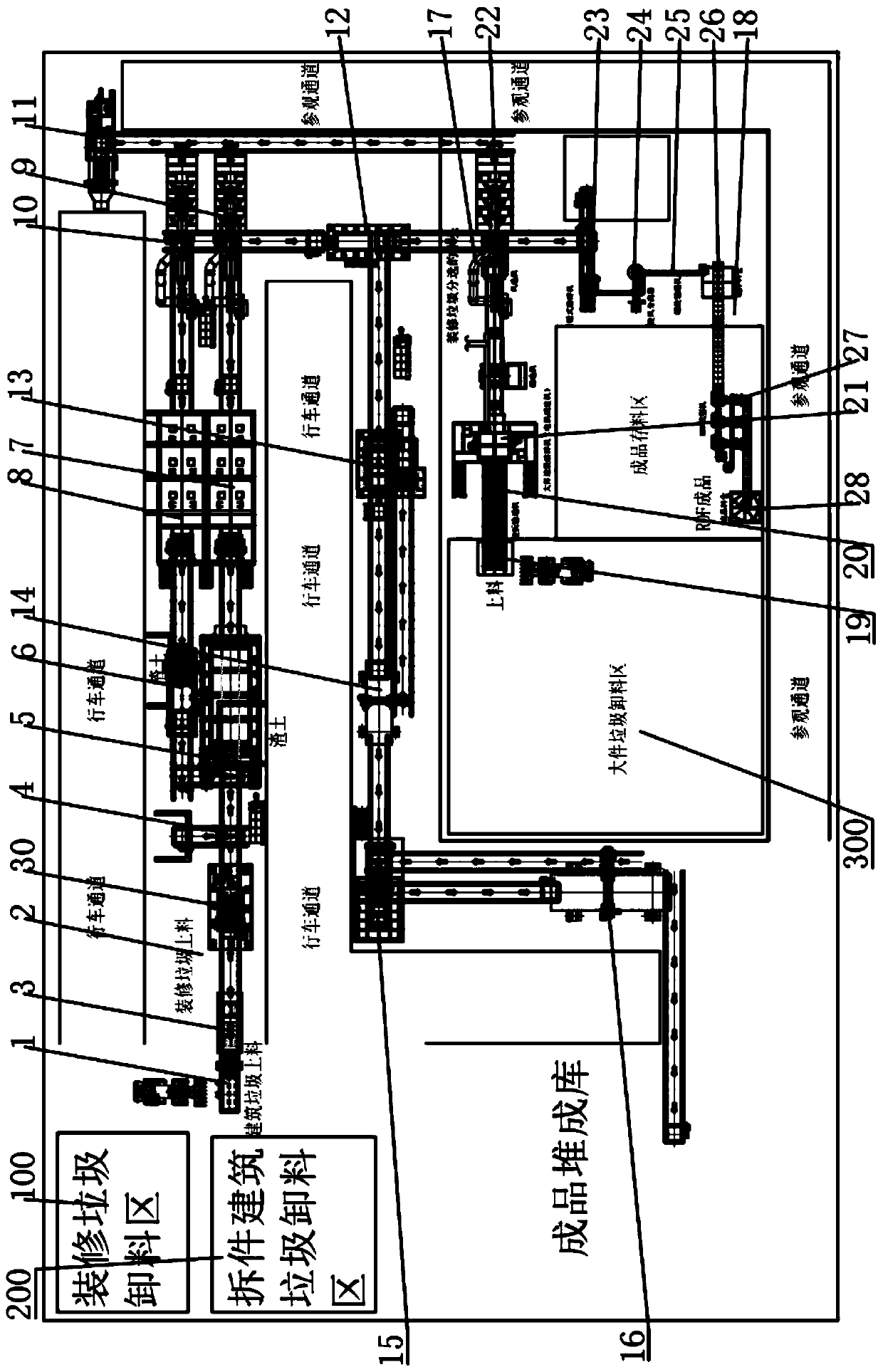

[0053] like figure 1 The construction and decoration waste automatic processing system shown includes construction waste feeding unit 1, decoration waste feeding unit 2, primary crushing unit 3, primary crushing unit 2 30, iron removal unit 4, and primary screening unit 1 5. First-level screening unit two 6. First-level manual sorting unit one 7. First-level manual sorting unit two 8. First-level winnowing unit one 9. First-level winnowing unit two 10. Packing unit 11. Smart photoelectric Sorting unit 12 , secondary crushing unit 13 , secondary screening unit 14 , tertiary crushing unit 15 , aggregate screening unit 16 , wood winnowing unit 17 and RDF molding unit 18 . The construction and decoration waste automatic processing system also includes an oversized waste loading unit 19 , an oversized waste conveying unit 20 , an oversized waste crushing unit 21 and an oversized waste magnetic separation unit 22 . The RDF molding unit 18 includes a wood crushing module 23 , a cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com