Hollow sphere photocatalyst as well as preparation method and application thereof

A photocatalyst and hollow sphere technology, applied in the field of photocatalysis, can solve problems such as high photogenerated carrier recombination rate, and achieve the effect of enhancing the capture ability, reducing the recombination probability and improving the photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a method for preparing the hollow sphere photocatalyst described in the above technical solution, comprising the following steps:

[0039] Depositing platinum ions on the surface of the spherical template to obtain a spherical template with platinum ions deposited on the surface;

[0040] After mixing the spherical template with platinum ions deposited on the surface, the alkaline solution and the titanium source solution, calcining to obtain a hollow sphere with Pt deposited on the inner surface;

[0041] The hollow sphere with Pt deposited on the inner surface is immersed in the source solution of the oxygen-promoting catalyst, and then calcined to obtain the hollow sphere photocatalyst.

[0042] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0043] The invention deposits platinum ions on the surface of the spherical tem...

Embodiment 1

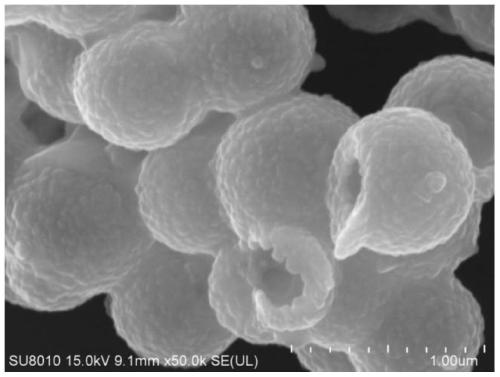

[0077] Add 1.2 mL of formaldehyde solution with a concentration of 410 g / L dropwise to a phenolic solution containing a basic catalyst (20 mL of absolute ethanol, 40 mL of deionized water, 0.2 mL of ammonia water with a concentration of 550 g / L and 1 g of 3-aminophenol) , after stirring for 30 hours, heat up to 100°C at a rate of 3°C / min to carry out hydrothermal reaction for 24h, centrifuge the hydrothermal reaction product, wash and dry the solid to obtain a spherical phenolic resin, denoted as APF;

[0078] Under ultrasonic conditions, 100mgAPF was impregnated into 50mL of chloroplatinic acid solution with a concentration of 10mg / mL (3h), the impregnation system was centrifuged, and the solid was dried to obtain a phenolic resin with platinum ions deposited on the surface, denoted as Pt 4+ @APF;

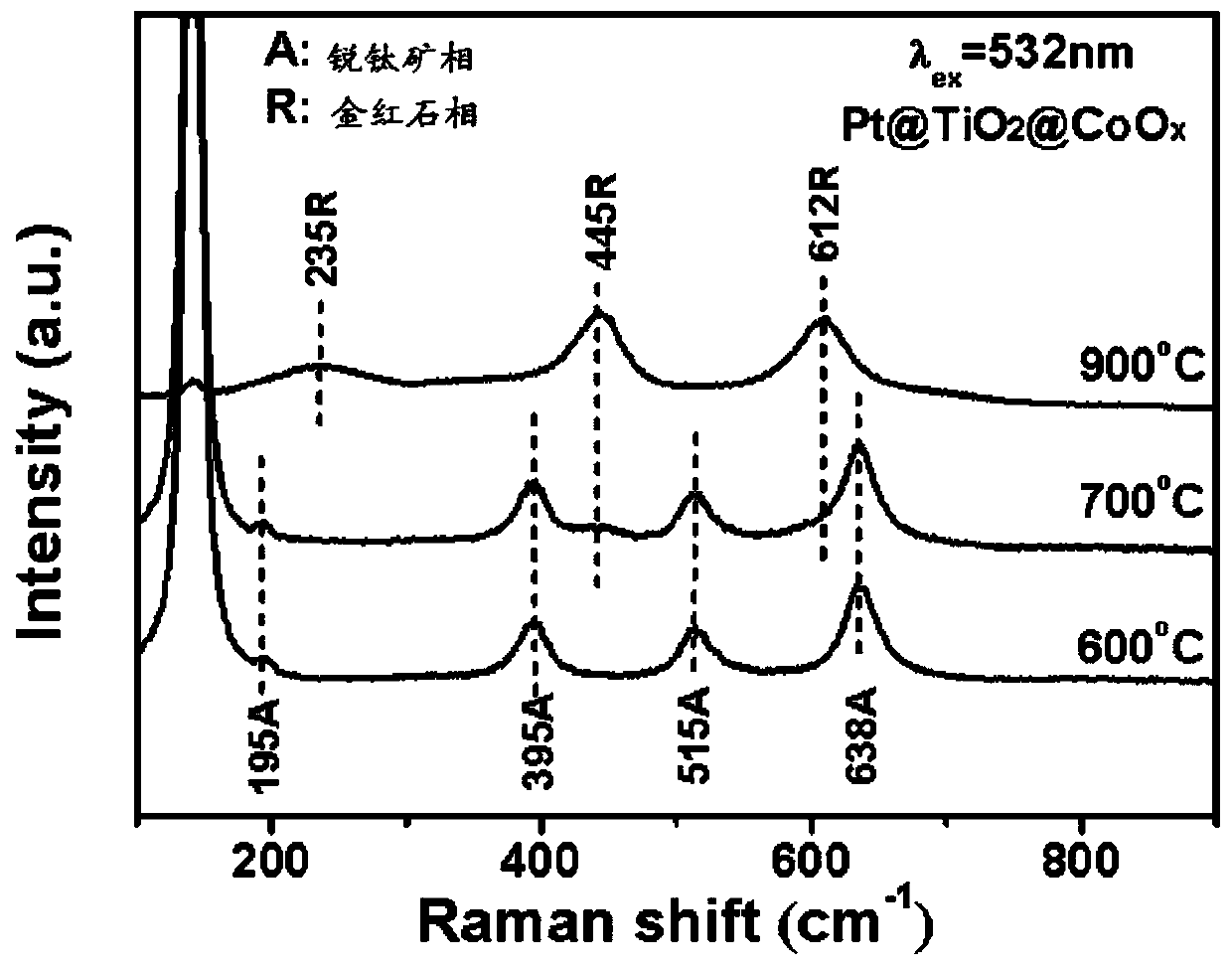

[0079] 0.1g of the Pt 4+ @APF Ultrasonic Dispersion Sonicate in 20mL absolute ethanol ice-water bath to disperse, add 7mL acetonitrile and 0.15mL ammonia water with a mass concen...

Embodiment 2

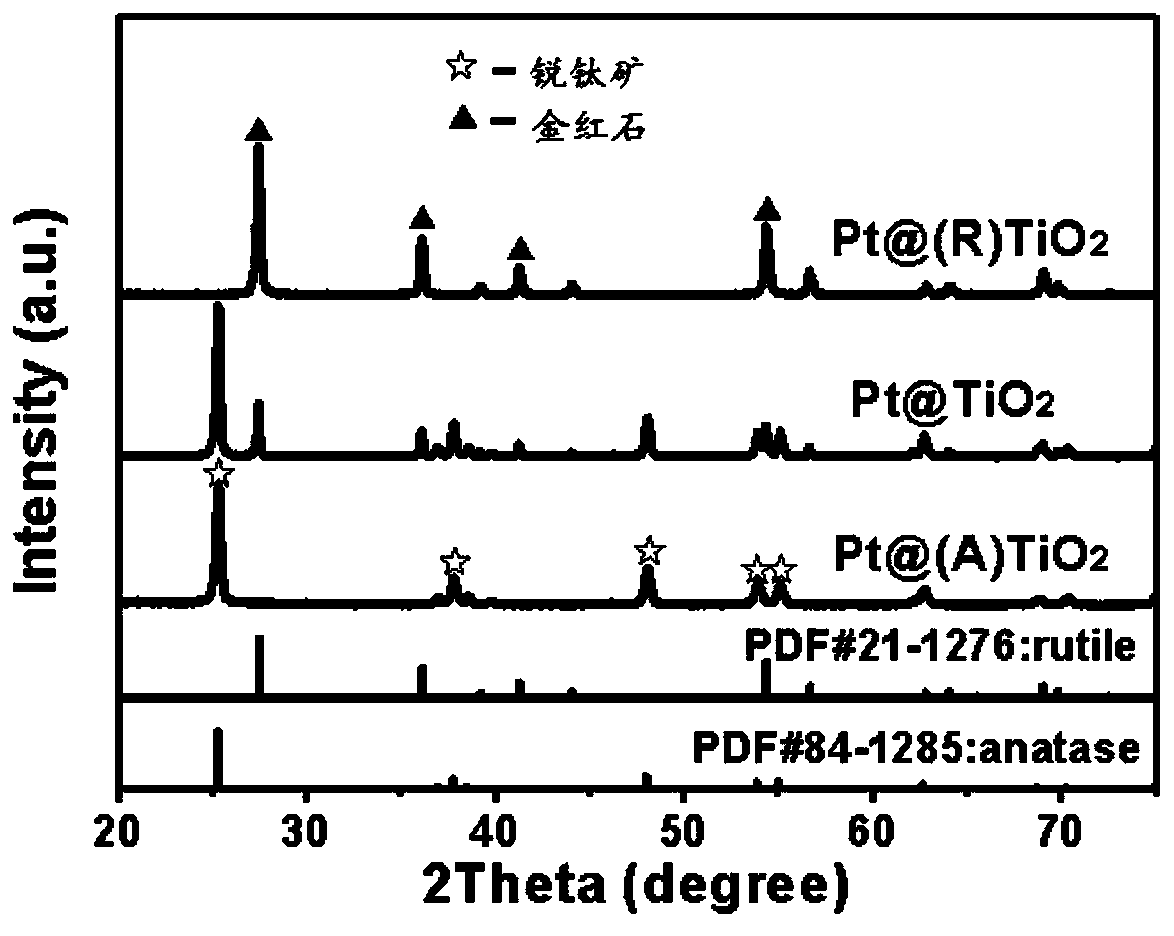

[0083] Referring to the preparation method of Example 1, the only difference is that the calcination temperature is 600°C to obtain a hollow sphere photocatalyst, which is denoted as 2-Pt@TiO 2 @CoO x (Pt accounted for the TiO 2 The mass percentage of the hollow sphere matrix is 0.3%, CoO x accounts for the TiO 2 The mass percentage of the hollow sphere matrix is 1.5%, anatase).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com