Hydrogenation catalyst and preparation method and application thereof

A technology of hydrogenation catalysts and additives, applied in chemical instruments and methods, preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of not reaching the industrialization level and high price, and achieve Increased unit activity, high selectivity, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] When the preparation method is a chemical precipitation method, the preparation method of the metal oxide carrier preferably includes the following steps:

[0042] Perform primary mixing of soluble subgroup metal salts and polar solvents to obtain a mixed solution;

[0043] After the mixed solution and the precipitating agent are mixed in two stages, the metal oxide carrier is obtained by standing for aging and calcining in sequence.

[0044] In the present invention, the soluble subgroup metal salt and the polar solvent are mixed in one stage to obtain a mixed solution;

[0045] In the present invention, the soluble subgroup metal salt preferably includes a soluble subgroup inorganic metal salt and / or a soluble subgroup alkoxy metal salt; in the present invention, the soluble subgroup inorganic metal salt preferably includes Ce, Ti, Soluble inorganic metal salts of Zr and Zn, more preferably one or more of soluble nitrates, chlorides, sulfates and carbonates of Ce, Ti...

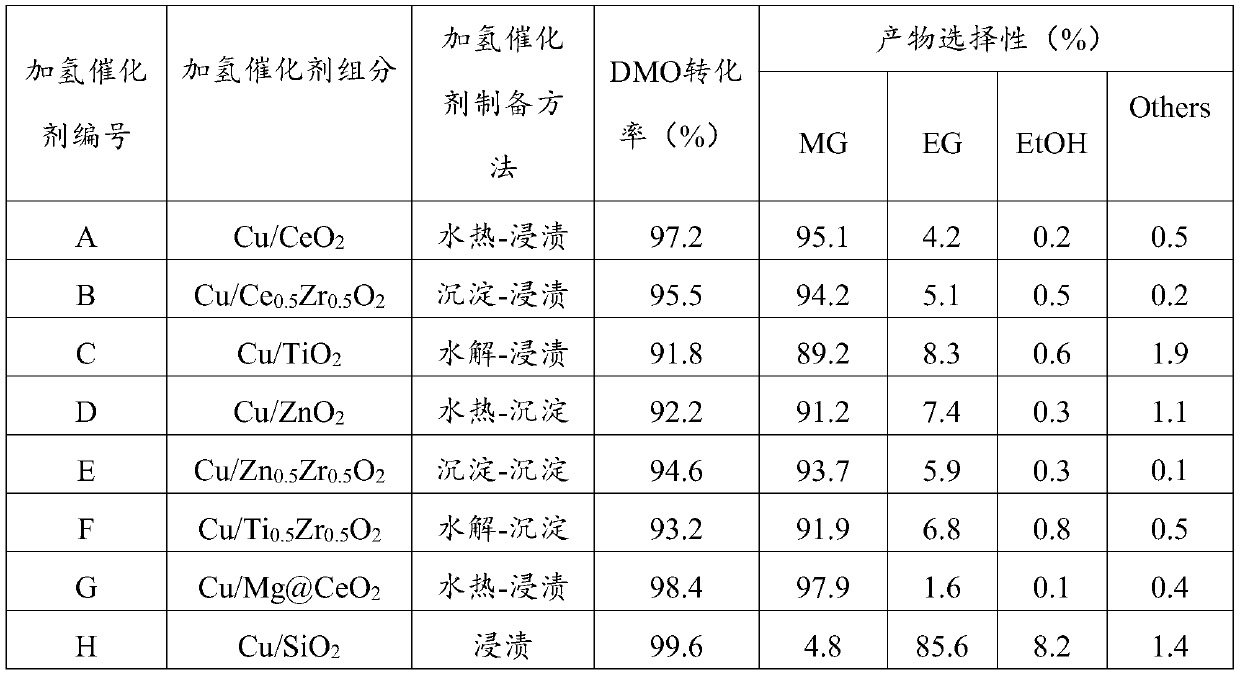

Embodiment 1

[0145] Mix 9.75g cerium nitrate and 50mL deionized water ultrasonically for 15min, the ultrasonic power is 40W, to obtain a mixed solution; add 4mol / L sodium hydroxide solution dropwise to the mixed solution, the dropping rate is 5 drops per second, in which hydrogen The molar ratio of sodium oxide and cerium nitrate is 3.0:1, stir evenly, transfer to a stainless steel hydrothermal kettle, heat at 150°C for 12h, leave it to age at room temperature for 2h, centrifuge the reacted mixed solution, and centrifuge the obtained product Washing was carried out sequentially, first washing twice with deionized water, then washing once with absolute ethanol, after washing until neutral, drying at 100°C for 12h, and then calcining at 500°C for 4h to obtain a cerium oxide carrier.

[0146] Mix 3.78g of copper nitrate trihydrate with 5mL of water to obtain an impregnating solution, immerse 4g of cerium oxide carrier in the impregnating solution for 12h, dry at 100°C for 12h, and then calcina...

Embodiment 2

[0149] 4.88g of cerium nitrate, 4.34g of zirconium oxychloride and 50mL of deionized water were ultrasonically mixed for 15min, and the ultrasonic power was 40W to obtain a mixed solution; the mixed solution was mixed with urea, wherein the moles of urea, cerium nitrate and zirconium oxychloride The ratio is 8:1:1; at 60°C, stir for 10 hours at a stirring speed of 500r / min, let it stand for aging at room temperature for 2 hours, then filter the mixed solution after the reaction, and wash the filtered product in turn until neutral. Drying at 100° C. for 12 hours, and then calcining at 500° C. for 4 hours to obtain a ceria-zirconia composite carrier.

[0150] Mix 3.78g of copper nitrate trihydrate with 5mL of water to obtain an impregnating solution, immerse 4g of cerium oxide-zirconia composite carrier in the impregnating solution for 12h, dry at 100°C for 12h, and then roast at 400°C for 4h; Hydrogenation catalyst precursor.

[0151] The hydrogenation catalyst precursor is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com