A kind of composite optical fiber and preparation method thereof

A composite material and optical fiber technology, applied in the directions of cladding optical fiber, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of super multi-core fiber preparation, high processing and molding difficulty, increasing application volume and preparation difficulty, and the overall size of super multi-core fiber. Large and other problems, to achieve the effect of improving the effective transmission distance, low cost, and easy shape adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

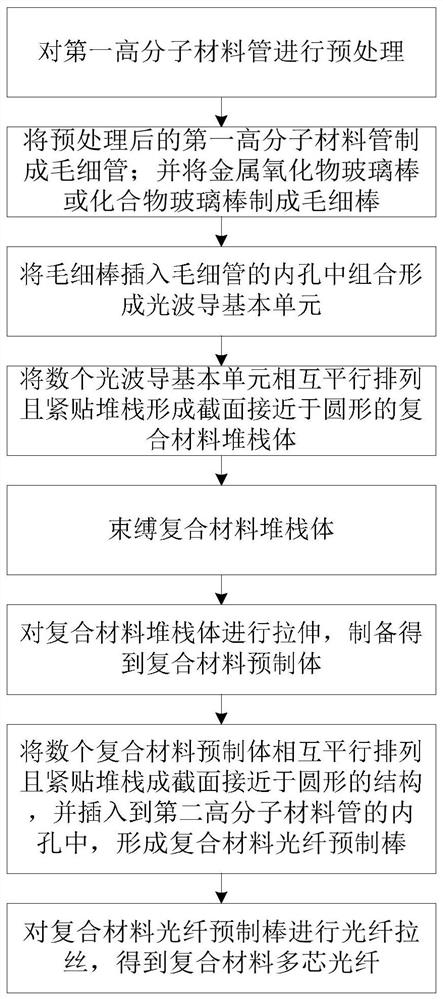

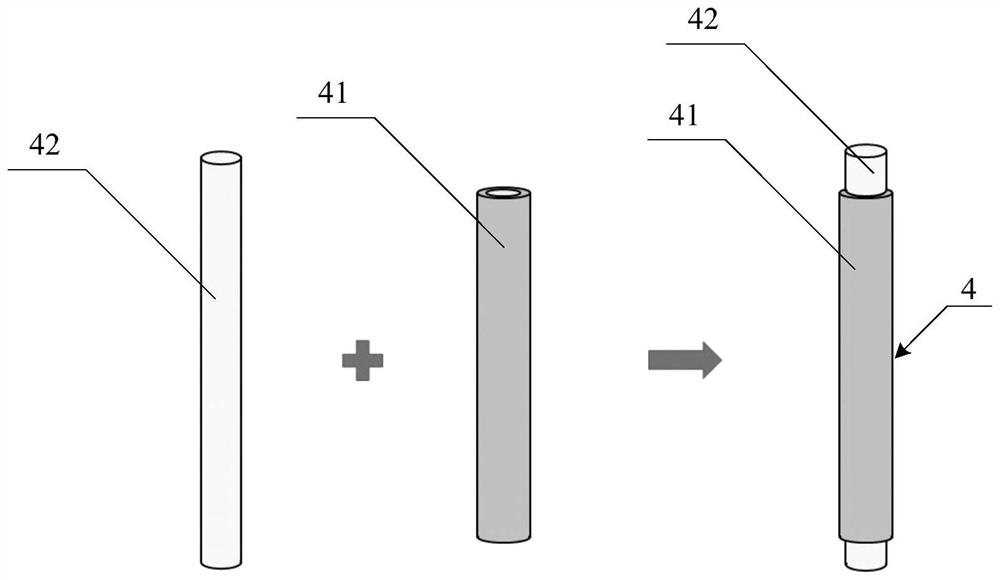

[0040] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

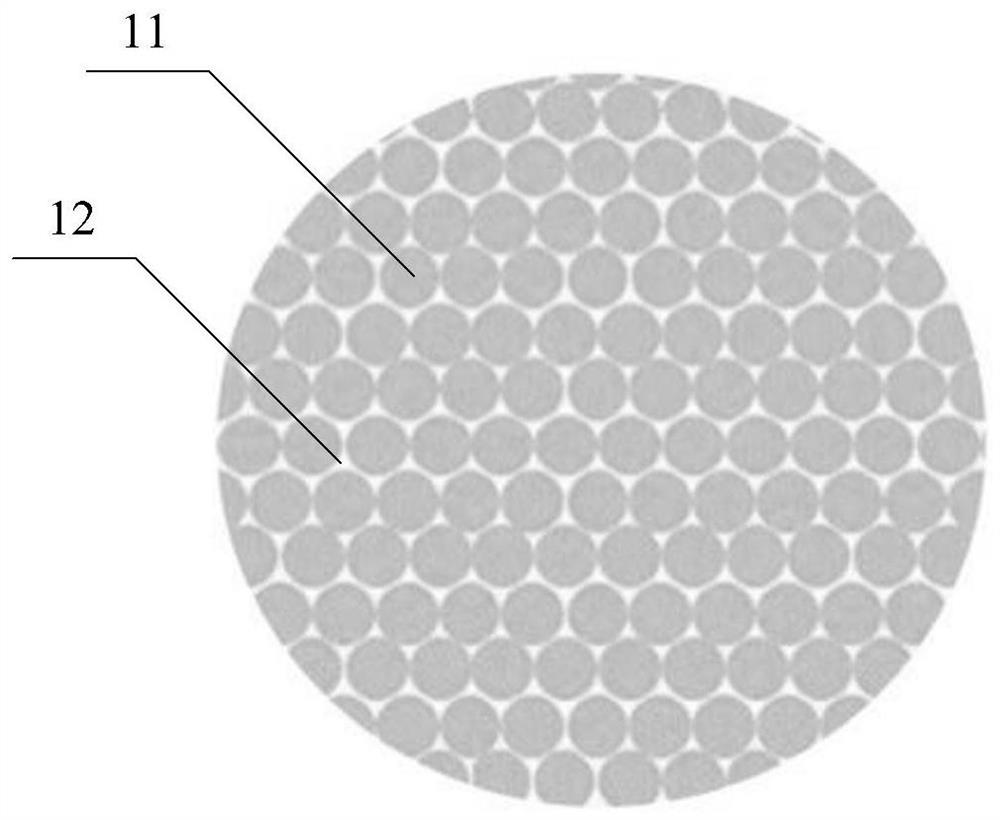

[0041] Composite material is an important branch of material science. The optical fiber material of a composite material optical fiber proposed by the present invention fully conforms to the definition of composite material: (1) The composite material must be artificial, and it is a material designed and manufactured by people according to their needs; (2) ) The composite material must be composed of two or more material components with different chemical and physical properties in the designed form, proportion and distribution, and there is an obvious interface between the components; (3) It has a structure Designability, composite structure design can be carried out; (4) composite materials not only maintain the advantages of the properties of each component material, but also obtain comprehensive properties that cannot be achieved by a sing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com