Long-service-life balanced tundish

A tundish and balanced technology, applied in the direction of casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems of limiting the continuous use time of tundishes, disrupting the production rhythm, increasing production costs, etc., to extend the continuous use time, reduce erosion, and prolong working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

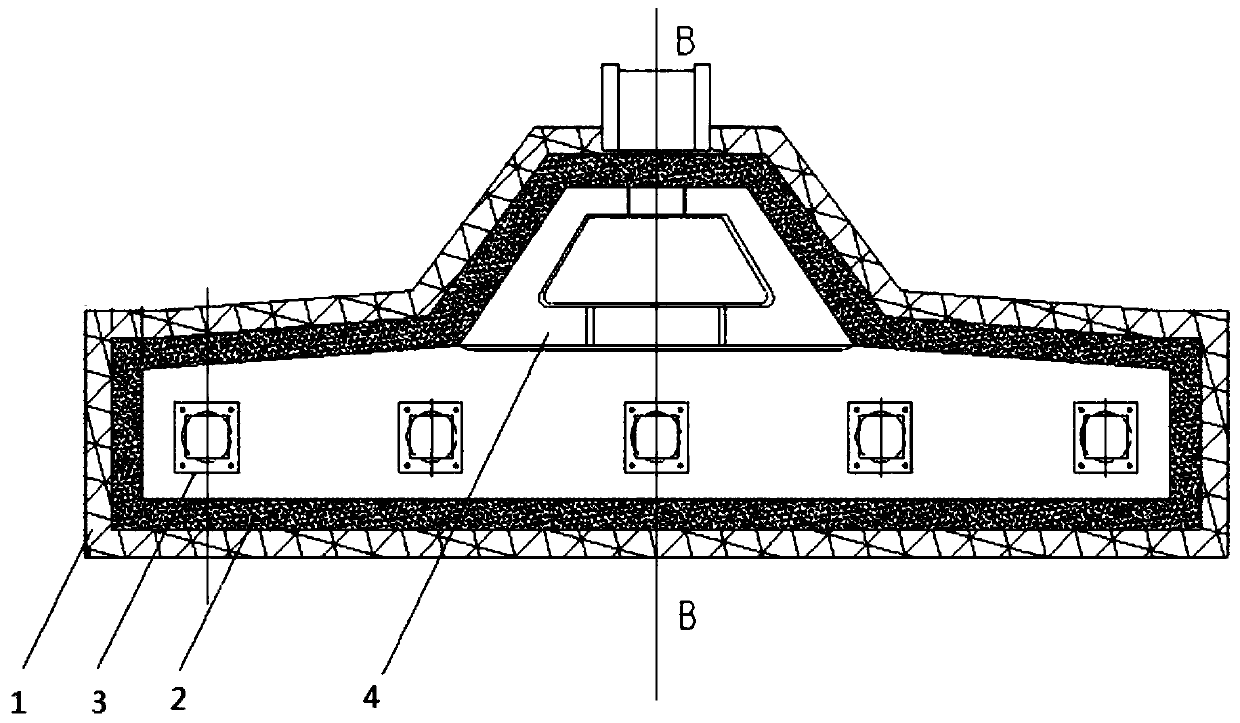

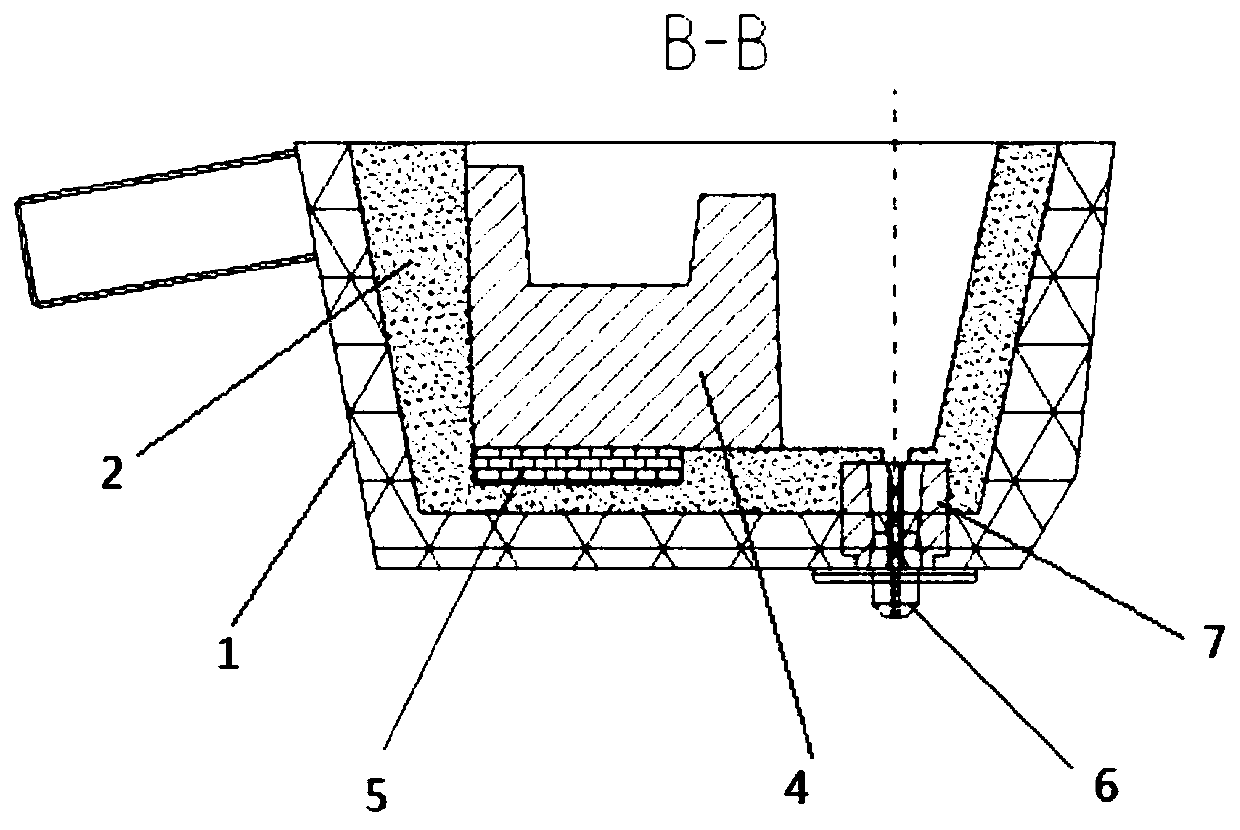

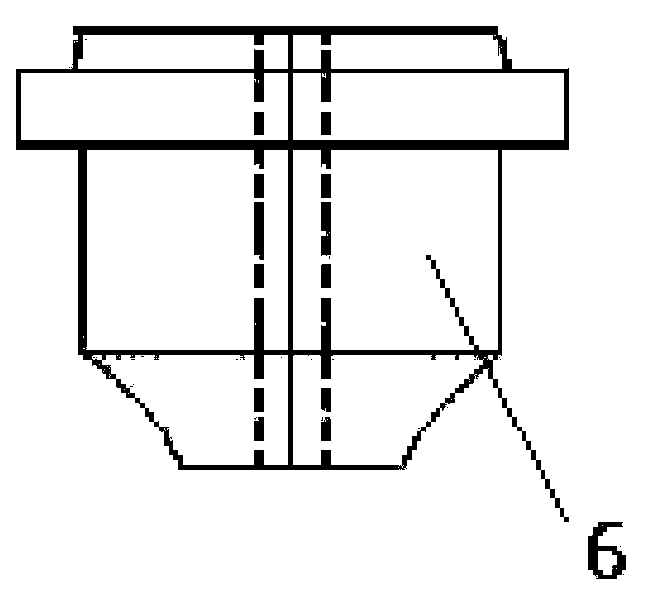

[0024] Such as Figure 1-Figure 4 As shown, a long-life balanced tundish includes a tundish main body, the tundish main body includes a permanent layer 1, a working layer 2 is provided on the inner side of the permanent layer 1, and the middle part of the cavity of the working layer is uniform A plurality of seat bricks 3 are provided. The working layer at the bottom, wall and slag line of the main body of the tundish is built with different dry materials, and the working layer at the bottom of the main body of the tundish has a mass content of 96% A dry material made by mixing high-purity magnesia and 3.5% solid resin powder, wherein the purity of the high-purity magnesia is 95%. The working layer located at the slag line of the tundish body is a dry material mixed with a mass content of 96% high-purity magnesia and 3.5% solid resin powder, wherein the purity of the high-purity magnesia is 97%. The working layer located at the cladding part of the tundish main body is a dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com