Euphausia superba pulverizing system and application thereof

An Antarctic krill meal and milling system technology, applied in application, food heat treatment, food freezing, etc., can solve the problems of loss of nutrients, changes in the properties of nutrients, denaturation, etc., and achieves low related costs, convenient transportation, and long shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

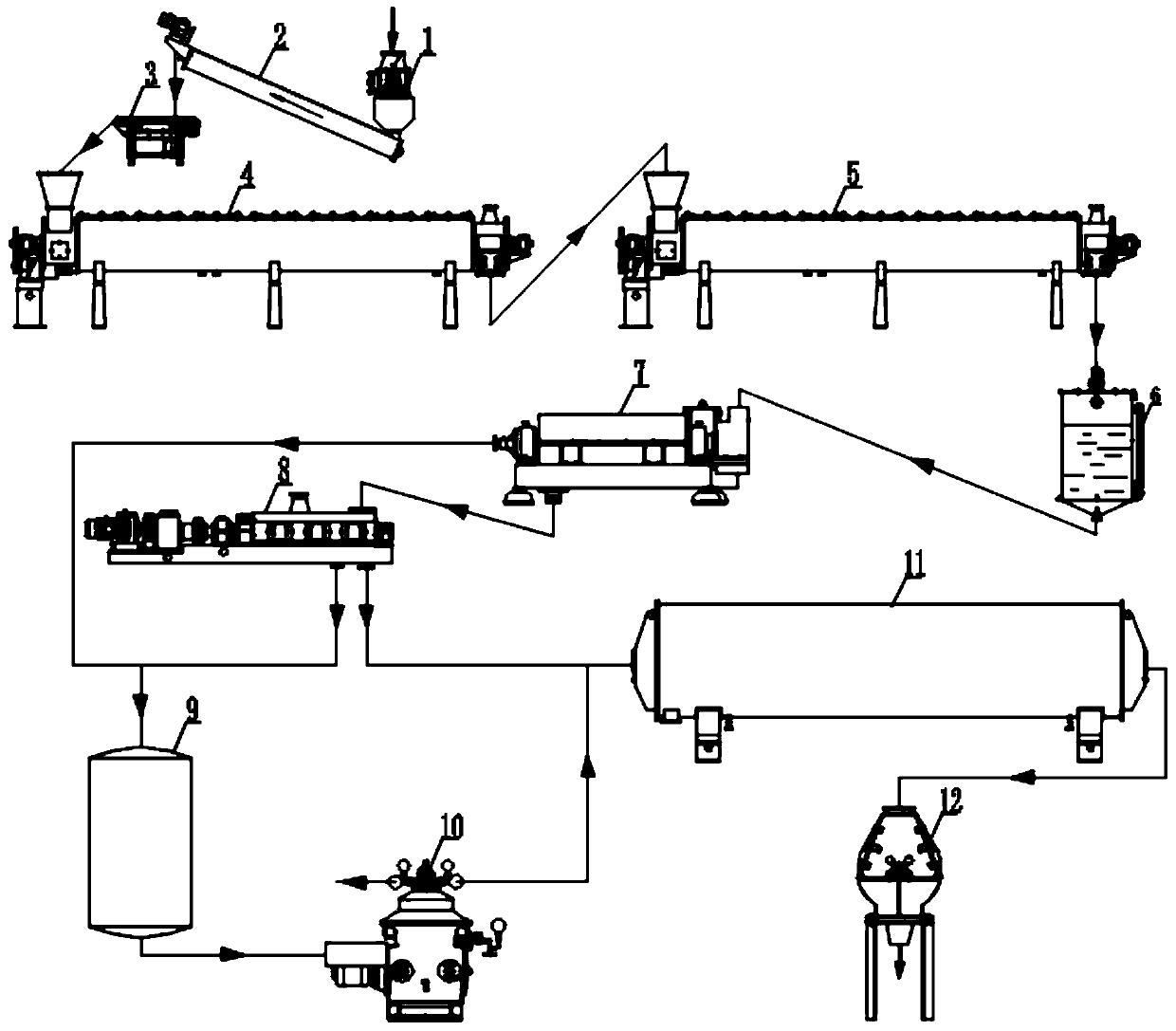

[0034] The specific embodiment of the present invention also provides a kind of preparation method of Antarctic krill meal, is to adopt above-mentioned system, comprises the following steps:

[0035] (1) Broken Antarctic krill into particles with a diameter of about 4-6 mm to facilitate the outflow of fat at high temperature, and then transport the broken krill to the metal detection process;

[0036] (2) After metal detection, the krill enters the first-level cooking machine and is cooked by indirect steam heating. The indirect heating temperature is ≤40°C, and the cooking time is controlled within 2 minutes;

[0037] (3) The krill after the first-level cooking enters the second-level cooking machine, and is cooked by direct steam heating, and the direct heating temperature is ≤85°C. In the closed cooking machine, the minced materials are easier to be heated quickly and evenly. It is easier to release fat. At this stage, the protein coagulates effectively and prevents oxidati...

Embodiment 1

[0041] This embodiment discloses a method for preparing ship-borne Antarctic krill powder, which adopts the above-mentioned system and method, and specifically includes: sending Antarctic krill into a crusher to be crushed into particles with a diameter of 4-6 mm, so as to facilitate fat removal under high temperature. Flow out, and then transport the broken krill to the metal detector through the conveying auger; after the metal detection is completed, the krill enters the first-level cooking machine and is cooked by steam indirect heating. The indirect heating temperature is 30°C and the cooking time is 1min; The first-level heated krill enters the second-level cooking machine and is cooked by direct steam heating. The direct heating temperature is 80°C. In the closed cooking machine, the minced materials are easier to be heated quickly and evenly, and are easier to release At this stage, the protein coagulates effectively and prevents oxidation; the cooking time is 1.5min, a...

Embodiment 2

[0045] This embodiment discloses a method for preparing ship-borne Antarctic krill powder, which adopts the above-mentioned system and method, and specifically includes: sending Antarctic krill into a crusher to be crushed into particles with a diameter of 4-6 mm, so as to facilitate fat removal under high temperature. Flow out, and then transport the broken krill to the metal detector through the conveying auger; after the metal detection is completed, the krill enters the first-level cooking machine and is cooked by steam indirect heating. The indirect heating temperature is 35°C and the cooking time is 1.5min ;The first-level heated krill enters the second-level cooking machine and is cooked by direct steam heating. The direct heating temperature is 82°C. In the closed cooking machine, the minced materials are easier to be heated quickly and evenly, and easier to release At this stage, the protein coagulates effectively and prevents oxidation; the cooking time is 1.5 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com