Horseradish tree leaf brown rice enzyme and preparation method thereof

A technology of Moringa oleifera leaves and Moringa oleifera leaf powder is applied in directions such as yeast-containing food ingredients, food ingredient functions, food drying, etc., and can solve problems such as unacceptable taste and roughness of brown rice, achieve better taste, prevent hemolysis, The effect of promoting iron absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

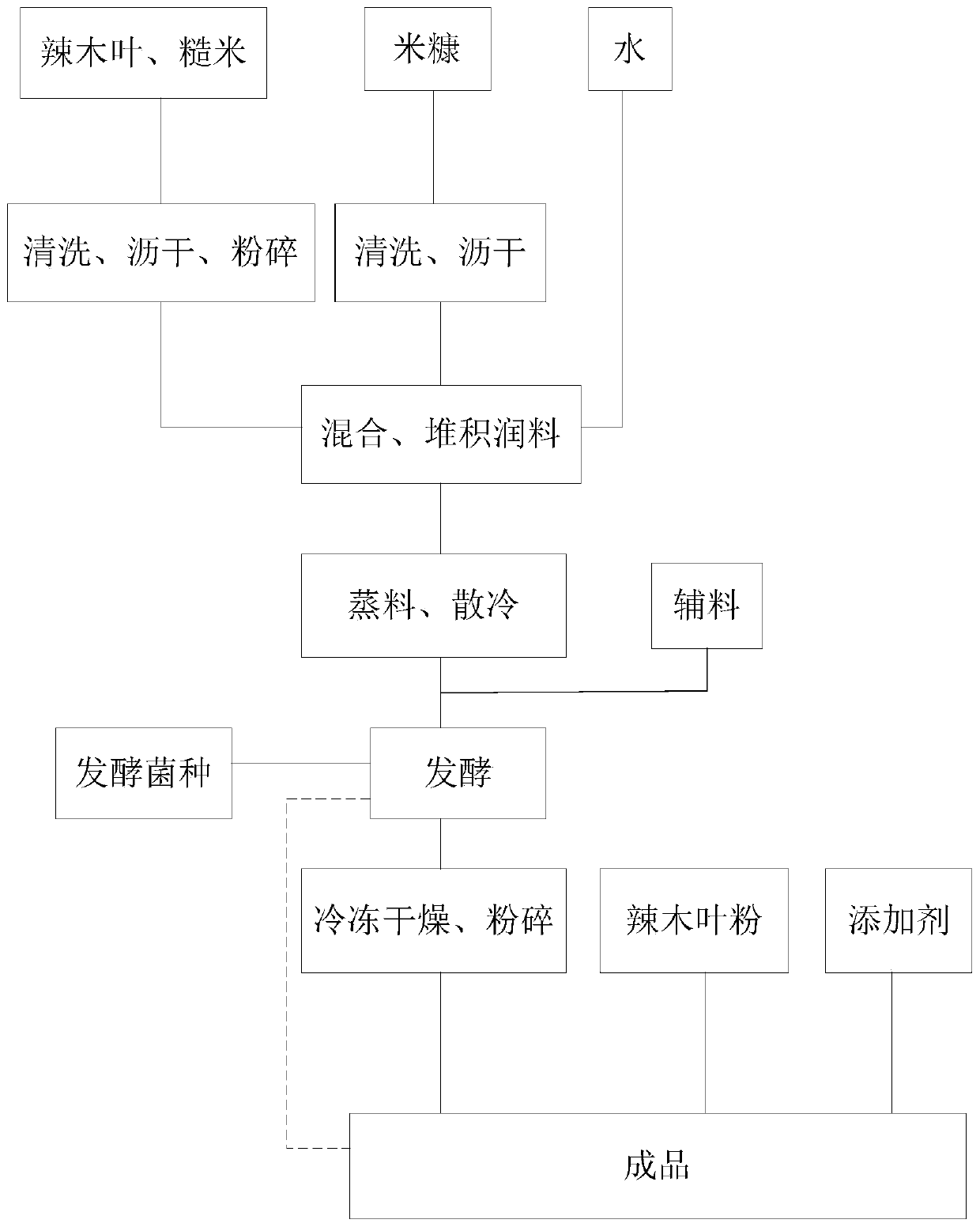

[0047] like figure 1 Shown, the preparation method of this Moringa leaf brown rice ferment comprises the following steps:

[0048] Step S1, preparing the enzyme body;

[0049] Step S2, according to (90-99): (1-10): (0.06-0.13) parts by weight, take the enzyme main body, Moringa leaf powder and additives, and mix them uniformly to obtain the finished product of Moringa leaf brown rice enzyme , wherein the main body of the enzyme is liquid or solid.

[0050] Further, the liquid enzyme body is made by the following preparation method:

[0051] Step 1. Washing the leaves of Moringa oleifera, brown rice and rice bran with clear water, draining, and then crushing the leaves of Moringa oleifera and brown rice respectively to make leaf of Moringa oleifera powder and brown rice flour, and put them aside for later use;

[0052]Step 2. Mix the Moringa oleifera leaf powder and brown rice powder prepared in step 1 with rice bran and water evenly, and carry out accumulation and moistenin...

Embodiment 1

[0062] Preparation of Moringa leaf brown rice enzyme powder.

[0063] Pick and clean Moringa leaves and brown rice, drain them, and crush them respectively to make Moringa leaf powder and brown rice powder, pass through a 40-mesh sieve and put them aside; take 100 kg of Moringa leaf powder and 900 kg of moringa leaf powder by weight. For brown rice flour, add 100 kg of rice bran powder and 400 kg of water, mix them evenly, accumulate and moisten the material for 80 minutes; after the accumulation and moistening treatment, steam the material at 100°C for 180 minutes, and then cool down to 40°C, add 1 kg of glutamic acid, 0.5 kg of cysteine and 1 kg of glycine, and mix well to make a fermentation base; add 40 kg of lactic acid bacteria and 20 kg of yeast to the fermentation base, of which lactic acid bacteria live The number of bacteria exceeds 10 10 cfu / ml, the viable count of yeast exceeds 10 12 cfu / ml, ferment at 30°C for 72 hours to make a liquid enzyme body; freeze-dry ...

Embodiment 2

[0065] Prepare Moringa leaf brown rice enzyme solution.

[0066] Moringa leaves and brown rice are selected and cleaned, drained, and crushed respectively, and the made Moringa leaf powder and brown rice powder are placed for later use after passing through a 40 mesh sieve; 100 kilograms of Moringa leaf powder, 900 1 kg of brown rice flour, then add 100 kg of rice bran powder and 400 kg of water, mix them evenly, accumulate and moisten the material for 80 minutes; after the accumulation of moistening material, steam the material at 100°C for 180 minutes, and then cool Cool down to 40°C, add 1 kg of glutamic acid, 0.5 kg of cysteine and 1 kg of glycine, and mix well to make a fermentation base; add 40 kg of lactic acid bacteria and 20 kg of yeast to the fermentation base, of which lactic acid bacteria The number of live bacteria exceeds 10 10 cfu / ml, the viable count of yeast exceeds 10 12 cfu / ml, ferment at 30°C for 72 hours to make liquid enzyme body; weigh 900 kg of liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com