A method for resource utilization of silicon tetrachloride pollutants

A technology of silicon tetrachloride and pollutants, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of strong toxicity, large pollution of silicon tetrachloride pollutants, high treatment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for resource utilization of silicon tetrachloride pollutants is to make silicon tetrachloride pollutants into a polysilicate composite flocculant. The specific preparation scheme is as follows: add 35g metal salt and 0.8 g coupling agent, after mixing evenly, control the temperature at 120°C, react for 15min, then add 8g of modified chitosan material, and continue the heat preservation reaction for 2h; then add 1000g of water to the mixing kettle, add inorganic acid to adjust the pH value to 1, and stir After uniformity, slowly add 80g of silicon tetrachloride pollutants into the mixing kettle within 60 minutes, stir and mix for 20 minutes after the addition is complete, then add to the reaction kettle, stir and mix evenly, control the temperature at 80°C, and react for 5 hours. The polysilicate composite flocculant is obtained.

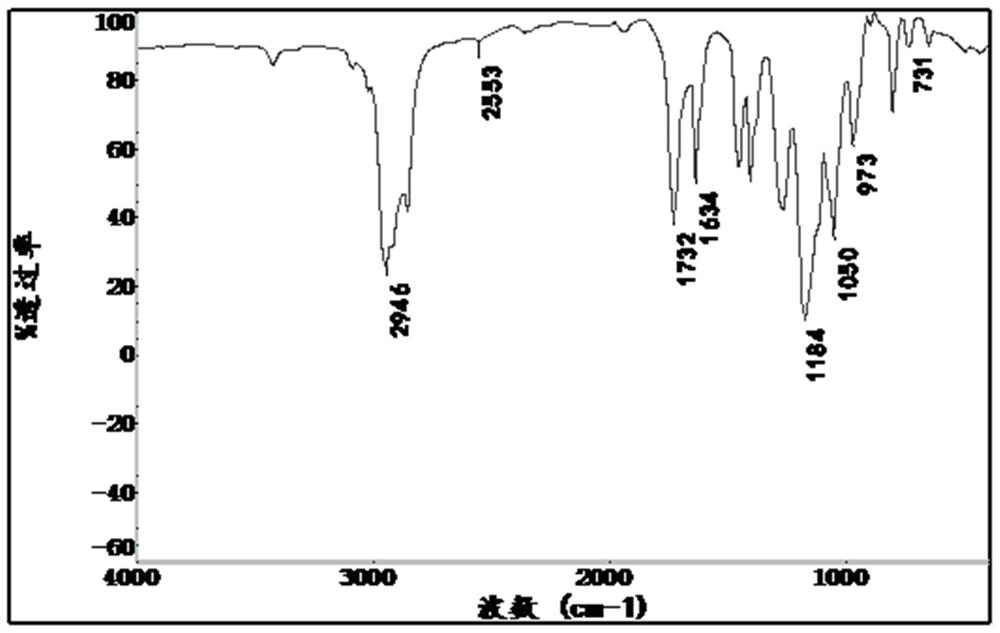

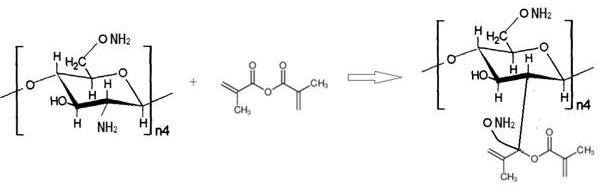

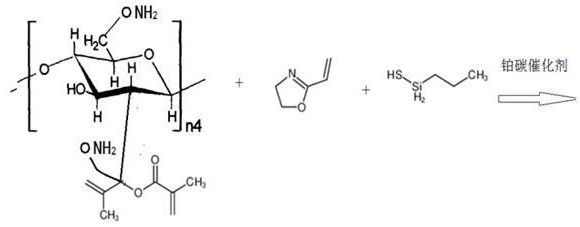

[0030] Described modified chitosan material is a kind of chitosan material containing oxazoline base, and its preparation method is ...

Embodiment 2

[0039]A method for resource utilization of silicon tetrachloride pollutants is to make silicon tetrachloride pollutants into a polysilicate composite flocculant. The specific preparation scheme is as follows: add 42g metal salt and 1.8 g coupling agent, after mixing evenly, control the temperature at 130°C, react for 20min, then add 9g of modified chitosan material, and continue the heat preservation reaction for 5h; then add 1300g of water into the mixing kettle, add inorganic acid to adjust the pH value to 2, stir After uniformity, slowly add 120g of silicon tetrachloride pollutants into the mixing kettle within 90 minutes, stir and mix for 25 minutes after the addition is complete, then add to the reaction kettle, stir and mix evenly, control the temperature at 95°C, and react for 6 hours. The polysilicate composite flocculant is obtained.

[0040] Described modified chitosan material is a kind of chitosan material containing oxazoline base, and its preparation method is as...

Embodiment 3

[0049] A method for resource utilization of silicon tetrachloride pollutants is to make silicon tetrachloride pollutants into a polysilicate composite flocculant. The specific preparation scheme is as follows: add 52g of metal salt and 3.4 g coupling agent, after mixing evenly, control the temperature at 150°C, react for 30min, then add 13g of modified chitosan material, and continue the heat preservation reaction for 7h; then add 1500g of water into the mixing kettle, add inorganic acid to adjust the pH value to 3, and stir After uniformity, slowly add 150g of silicon tetrachloride pollutants into the mixing kettle within 120min, stir and mix for 30min after the addition is complete, then add to the reaction kettle, stir and mix evenly, control the temperature at 110°C, and react for 8h. The polysilicate composite flocculant is obtained.

[0050] Described modified chitosan material is a kind of chitosan material containing oxazoline base, and its preparation method is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com