Grinding machine with efficient dust removing function

A grinding machine and functional technology, applied in the direction of grinding machines, dust removal, manufacturing tools, etc., can solve problems such as pollution, mechanical equipment damage, and affecting the health of operators, and achieve the effects of saving water resources, preventing injuries, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

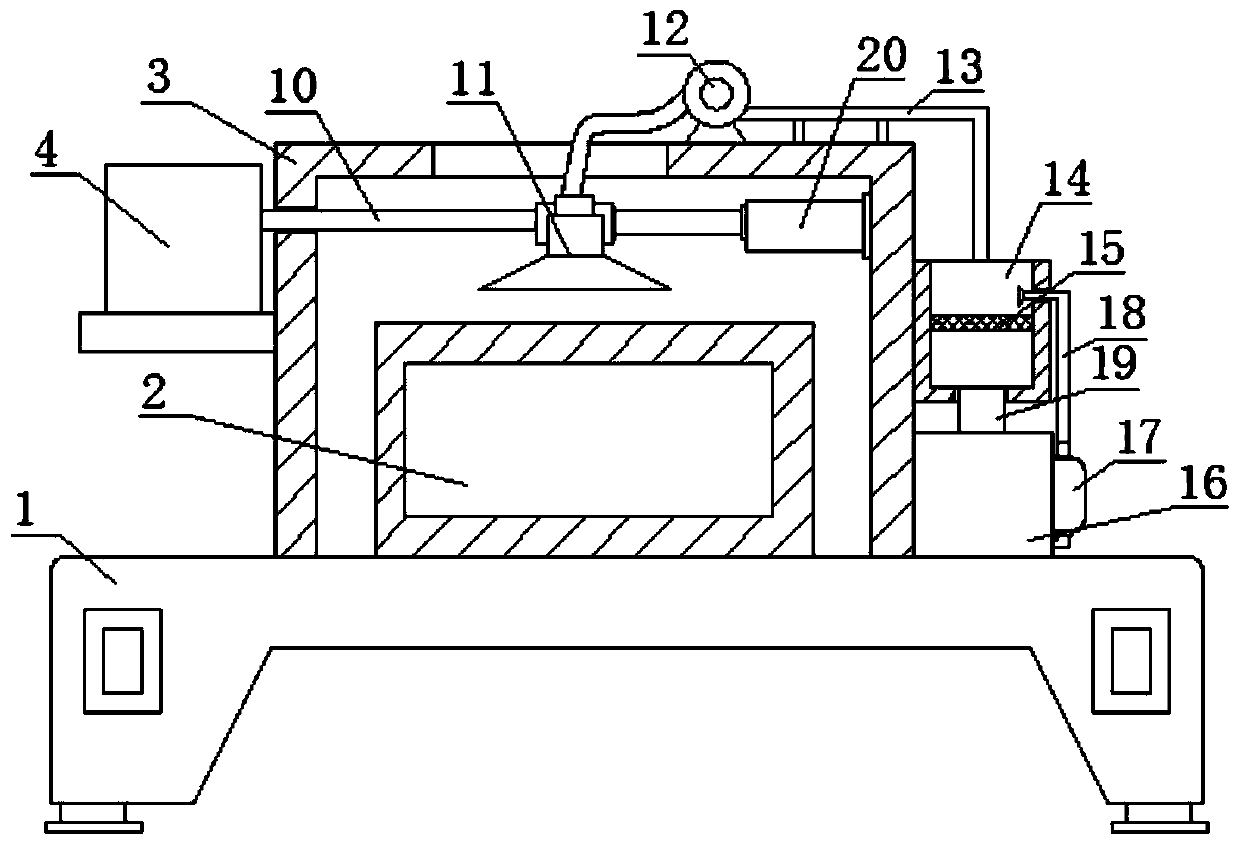

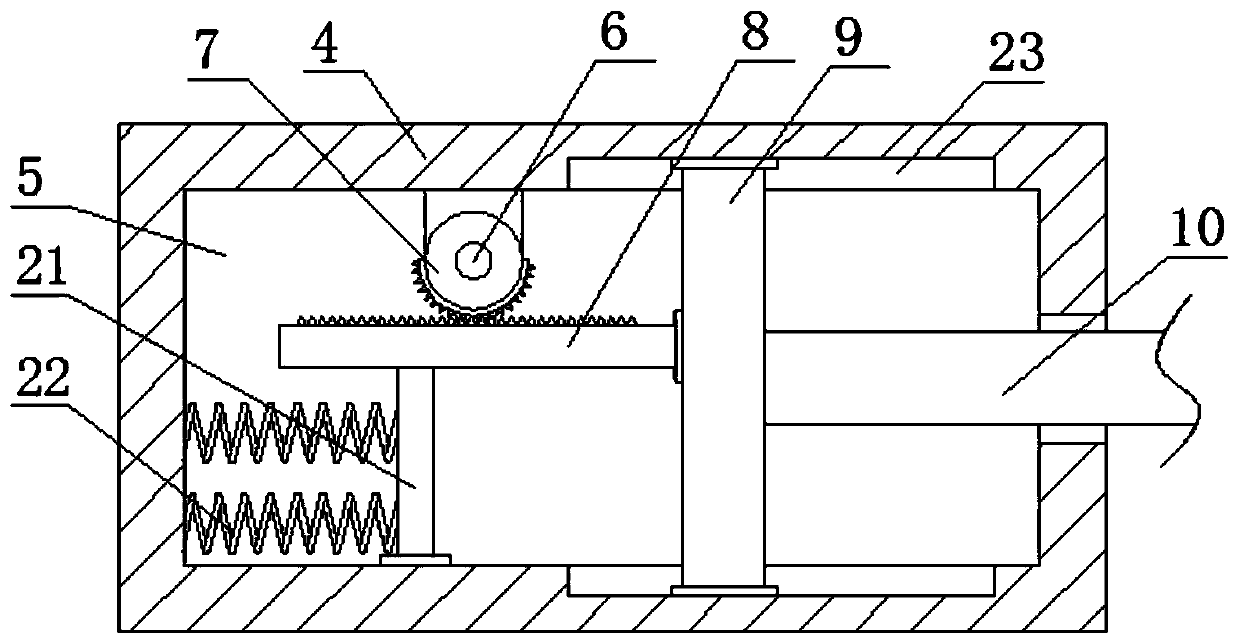

[0020] refer to Figure 1-3 , a grinding machine with high-efficiency dust removal function, comprising an operating table 1, the top of the operating table 1 is fixedly connected with a grinder main body 2, the top of the operating table 1 is fixedly connected with a dust-proof frame 3, and the grinding machine main body 2 is located in the dust-proof frame 3, One side of the dust-proof frame 3 is fixedly connected with a support plate, the top of the support plate is fixedly connected with a fixed seat 4, the fixed seat 4 is provided with a fixed chamber 5, and the top inner wall of the fixed chamber 5 is fixedly connected with a drive motor 6, A half gear 7 is fixedly sleeved on the output shaft of the drive motor 6, a sliding plate 9 is slidably connected in the fixed chamber 5, a rack 8 is fixedly connected to one side of the sliding plate 9, and the half gear 7 is intermittently meshed with the rack 8. A moving rod 10 is fixedly connected to the other side of the sliding...

Embodiment 2

[0022] In the present invention, the bottom of the dust collecting box 14 is sealed and fixedly connected with a connecting pipe 19, the bottom end of the connecting pipe 19 extends into the water tank 16, and the connecting pipe 19 is provided to return the filtered water to the water tank 16 for recycling. , saving water resources.

[0023] In the present invention, a telescopic rod 20 is fixedly connected to the inner wall of one side of the dust-proof frame 3, and one end of the telescopic rod 20 is fixedly connected to one side of the dust hood 11. The telescopic rod 20 can provide support for the dust hood 11, and can The dust cover 11 can be moved smoothly.

[0024] In the present invention, the top inner wall and the bottom inner wall of the fixed chamber 5 are provided with sliding grooves 23, and the top and bottom of the sliding plate 9 are respectively slidably connected to the inner walls of the two sliding grooves 23 away from each other. The sliding grooves 23 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com