Numerical control machine tool equipment capable of improving equipment reliability by improving environmental friendliness

A CNC machine tool and reliability technology, applied in metal processing equipment, dispersed particle filtration, metal processing machinery parts, etc., can solve problems such as high cost and affect the reliability of CNC machine tools, and achieve the effect of improving processing accuracy and ensuring clean and tidy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

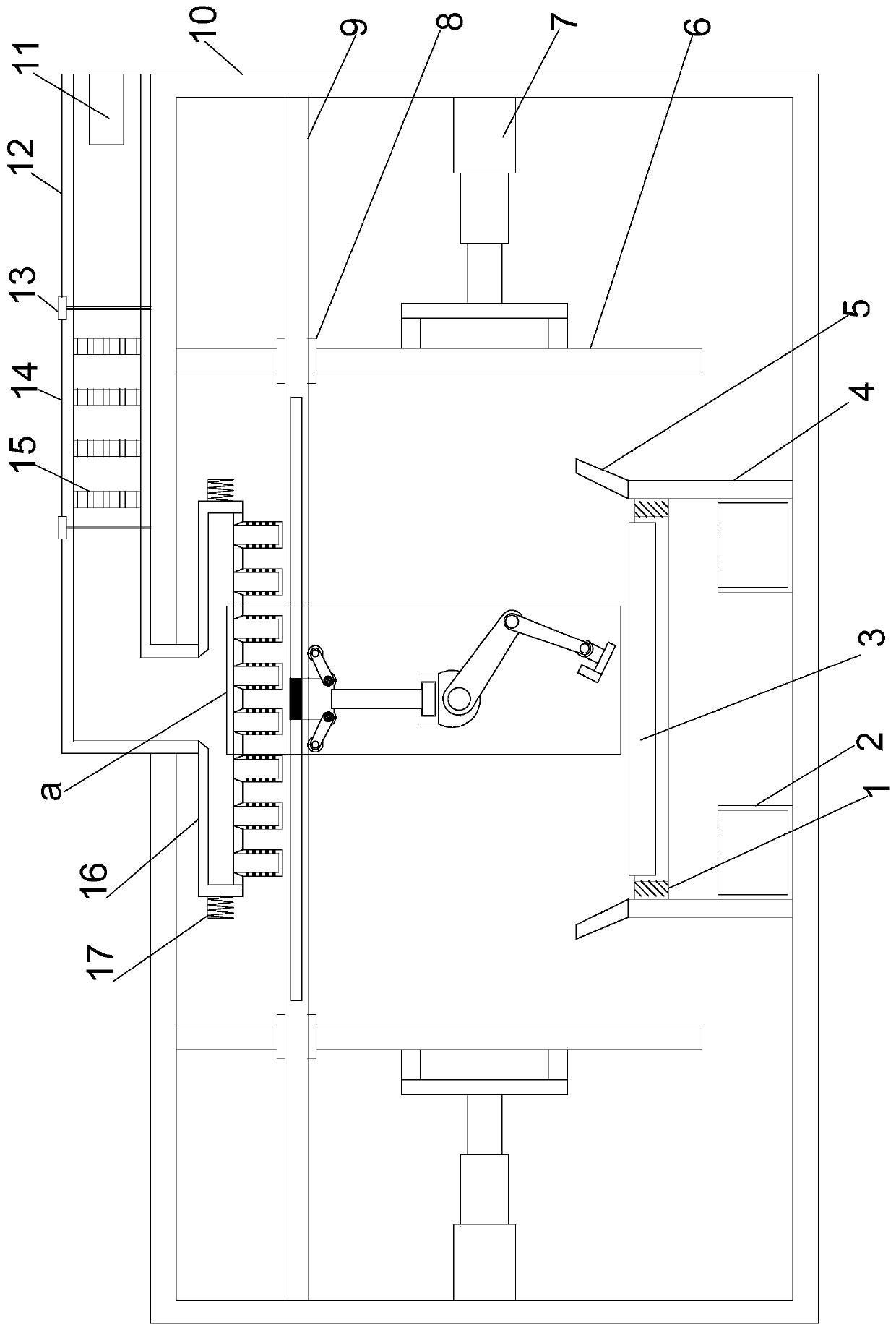

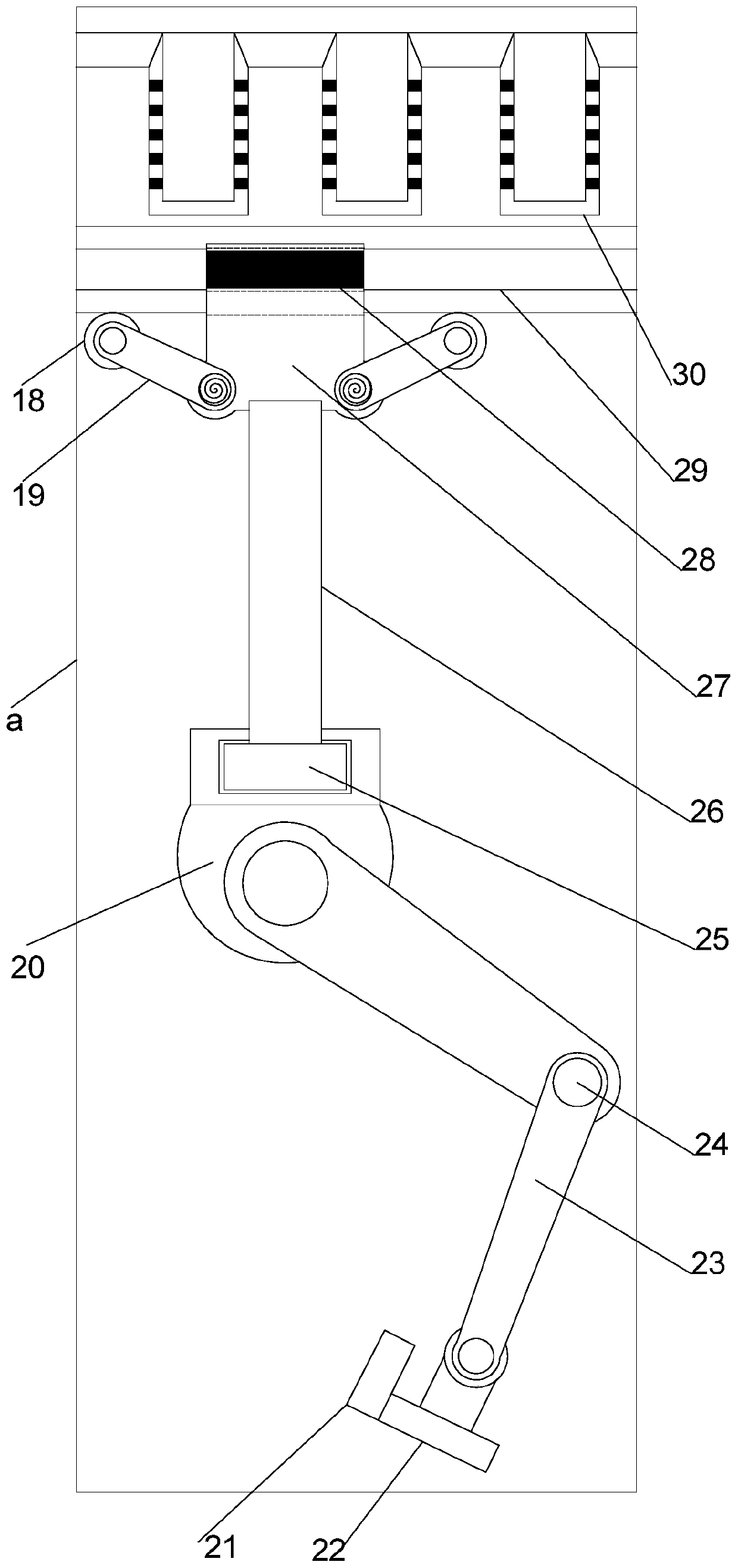

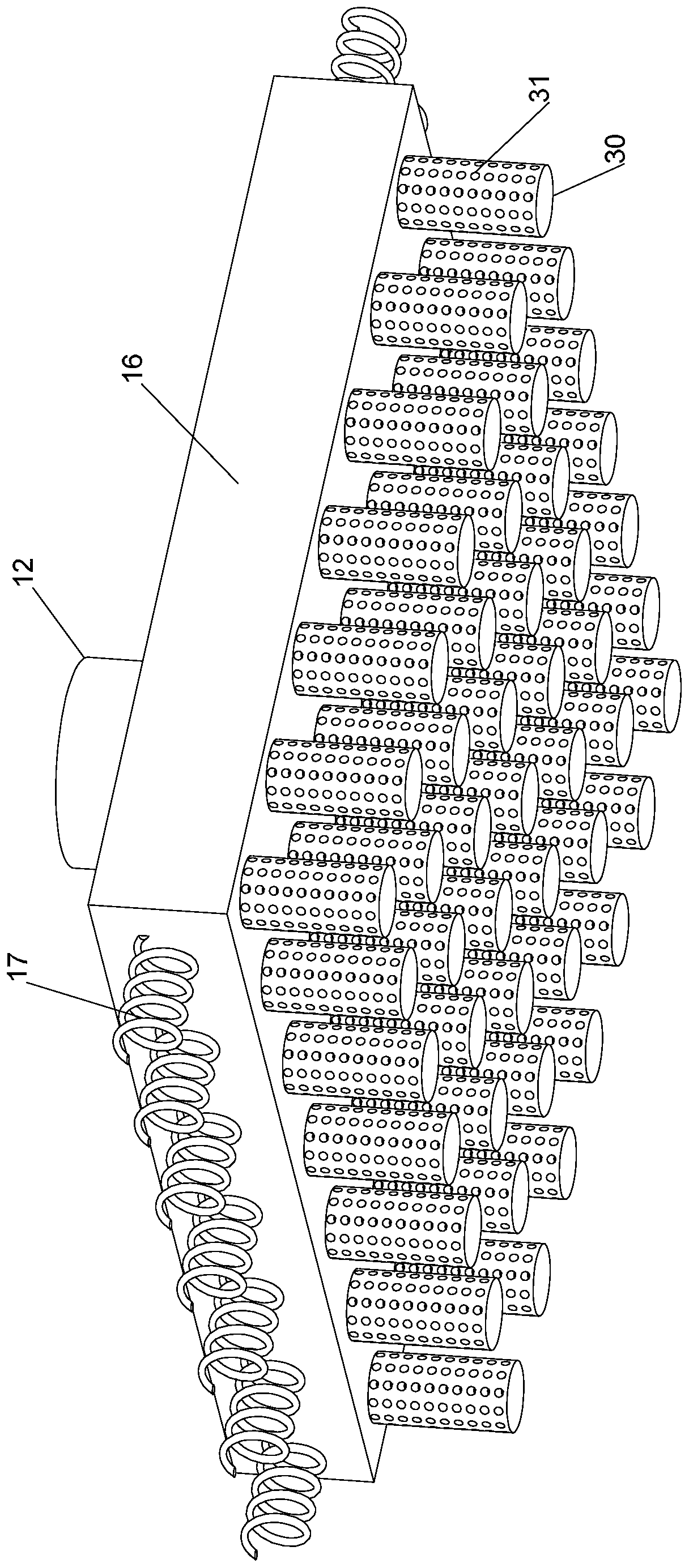

[0021] see Figure 1~3 , in an embodiment of the present invention, a CNC machine tool equipment that improves equipment reliability by improving environmental protection, includes a vertically arranged support installation cover 10, and a support installation cylinder 4 is vertically provided at the middle position of the bottom of the support installation cover 10, The upper end of the support installation cylinder 4 is horizontally provided with a translational installation platform 3, and the inner upper half of the support installation cover 10 is horizontally provided with a guide support column 9, and both sides of the middle area of the guide support column 9 are horizontally provided with guide movement grooves 29, The middle position of the guide support column 9 is vertically provided with a mobile mounting cylinder 27, and the inner side of the mobile mounting cylinder 27 cooperates with the guide moving groove 29 to be provided with a guiding mobile column 28, an...

Embodiment 2

[0024] On the basis of Embodiment 1, during the moving process of the mobile installation cylinder 27, due to the cooperation of the guide moving groove 29 and the guide moving column 28, the moving process is smooth and stable. There is always a rotational stress, so that the driving guide wheel 18 is always in contact with the guide support column 9, which ensures the realization of the movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com