Shaping and edge cutting stamping die

A stamping die and edge trimming technology, which is applied in the field of shaping and trimming stamping dies, can solve the problems of high mold cost and low pass rate, and achieve the effects of low cost, improved pass rate, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

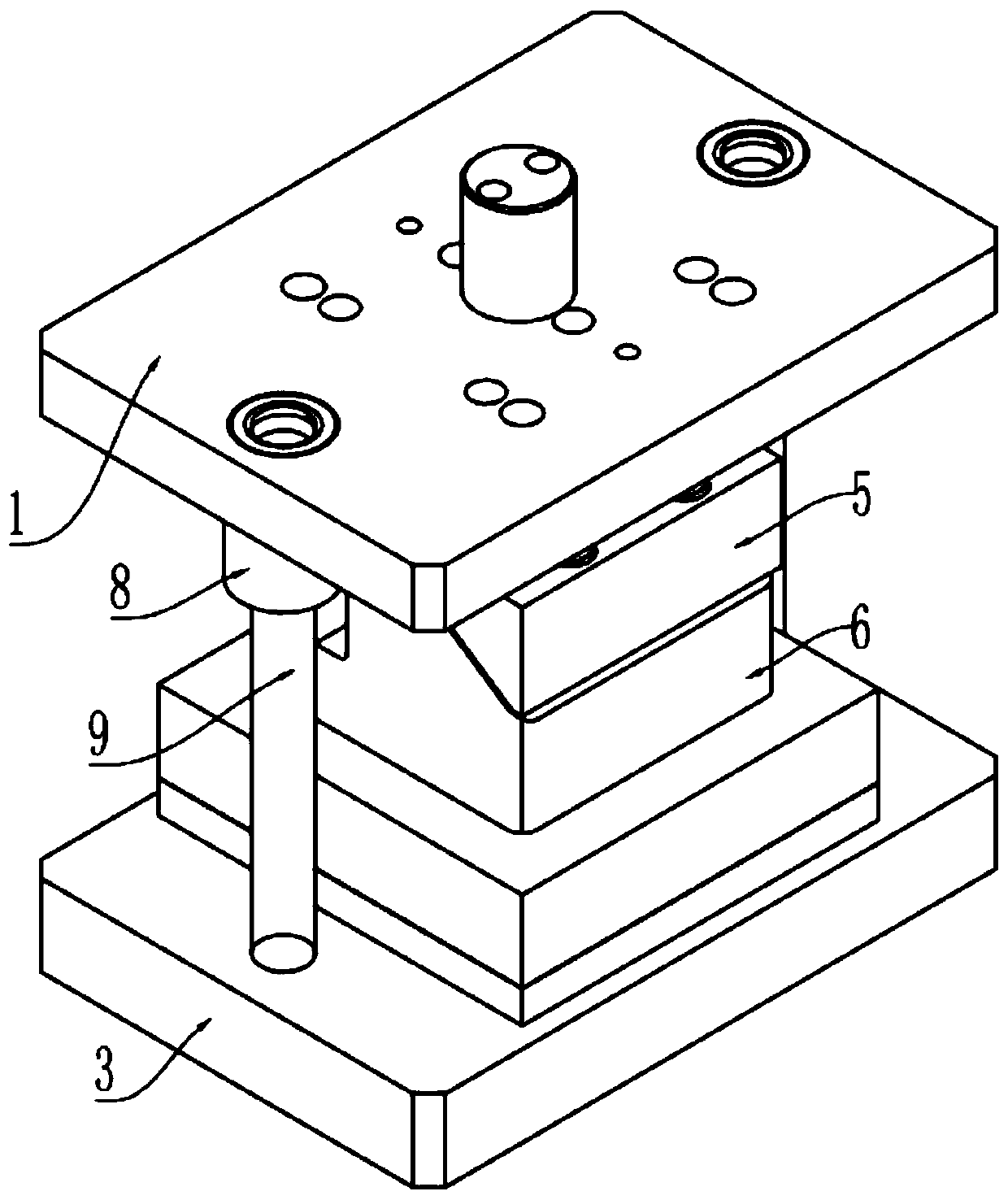

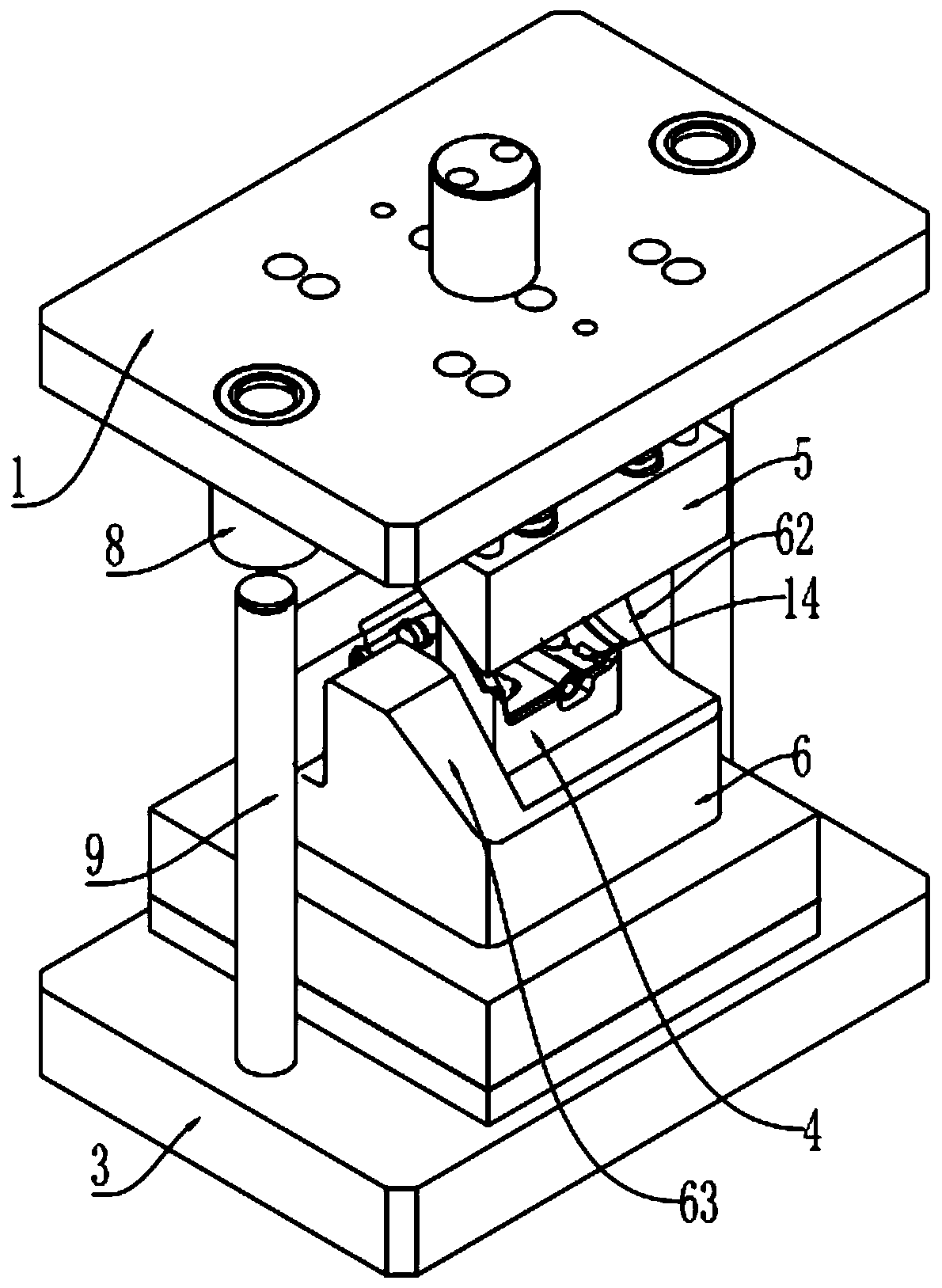

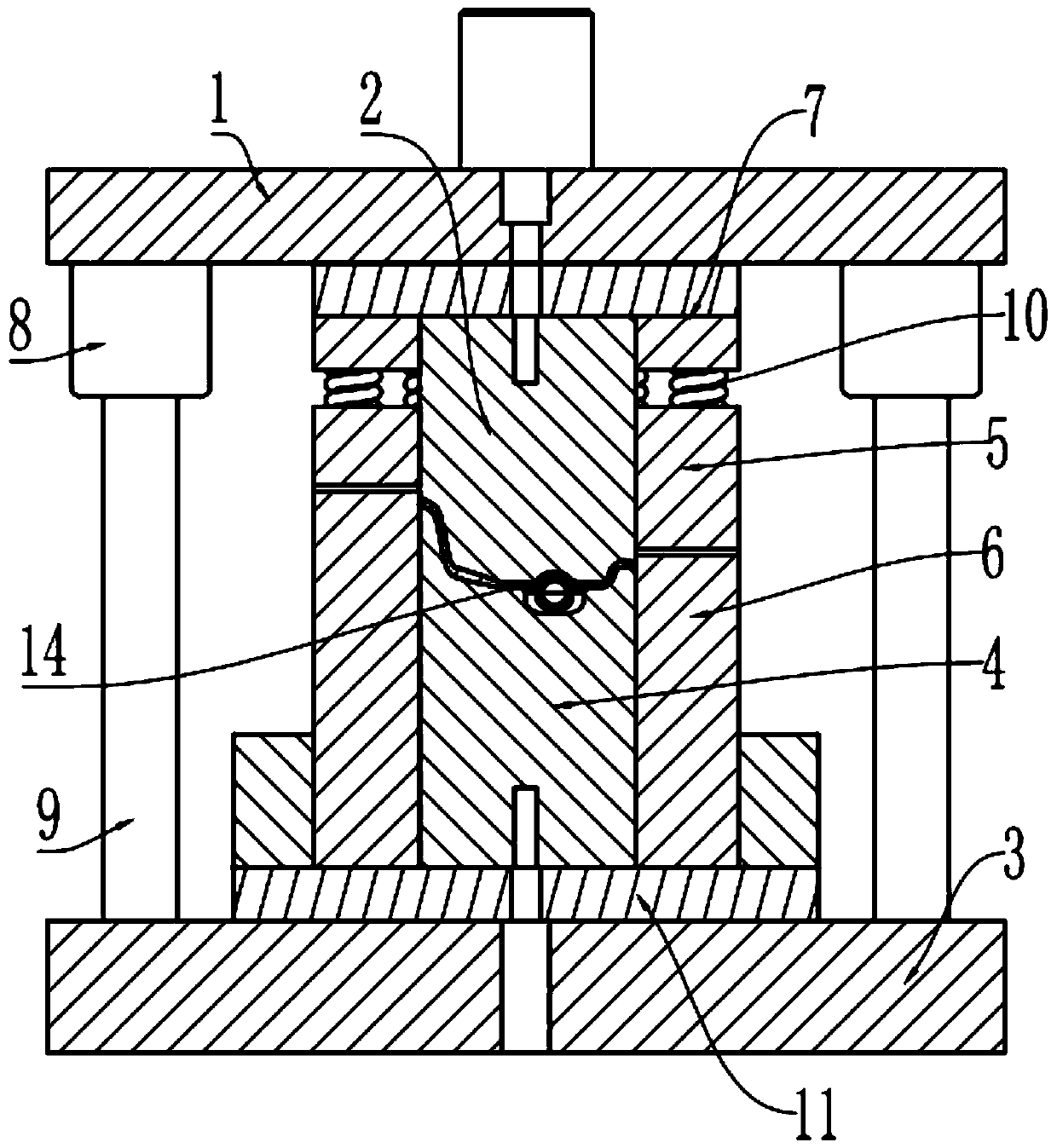

[0039] Embodiment one is basically as attached Figure 1 to Figure 5 Shown:

[0040] Stamping mold for shaping and trimming, including upper mold base 1, upper mold plate 2, lower mold base 3, lower mold plate 4, upper platen 5 and lower platen 6, upper platen 2 and upper mold base 1 are fixedly connected by bolts Plate 7, the upper mold base 1 is fixedly connected with a guide sleeve 8, the lower mold base 3 is fixedly connected with a guide post 9 that can be inserted into the guide sleeve 8, and the upper die base 1 can move vertically along the guide post 9; Pressing plate 5 is positioned at the bottom of upper backing plate 7, and vertical sliding connection is connected with connector 13 on the upper backing plate 7, and the lower end of connector 13 passes through upper backing plate 7 and is screwed on the upper pressing plate 5, and the upper end of connector 13 vertically Slidingly connected on the upper backing plate 7, the upper template 2 is set in the middle of ...

Embodiment 2

[0052] Embodiment two is basically as attached Figure 6 As shown, Embodiment 2 has made the following improvements on the basis of Embodiment 1: There is a horizontal chute in the lower formwork 4, and a push block 15 with a wedge surface is connected to the horizontal slide in the chute, and the wedge surface of the push block 15 Downward, the push block 15 can stick to the curved surface 62 on the lower pressing plate 6, and a third elastic member is welded between the push block 15 and the bottom of the chute, and the third elastic member adopts a spring.

[0053] The screw on the lower platen 6 is connected with a guide plate 16, and the guide plate 16 is provided with a guide groove. The end rests on the opening of the collection box 17.

[0054] The specific implementation process is as follows:

[0055] During the mold opening process of the upper template 2 and the lower template 4, the lower template 4 moves upward under the action of the second elastic member 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com