Compression granulator

A technology of compressing granulator and machine head, which is applied in the direction of making medicines into special physical or taking forms, which can solve the problems of poor particle size uniformity and achieve stable operation, good reliability and high molding quality of the equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

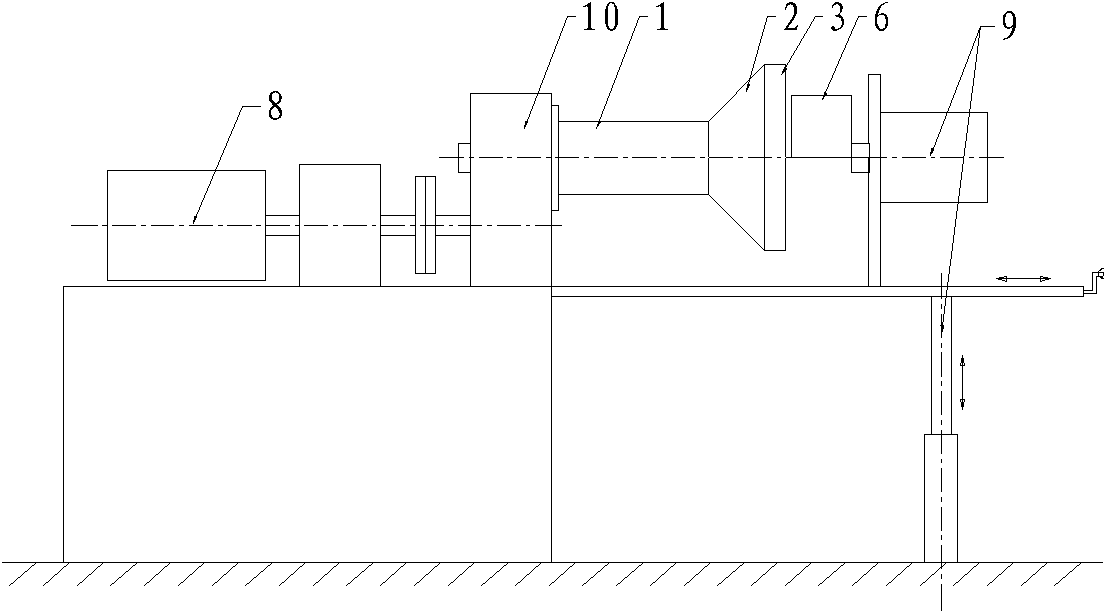

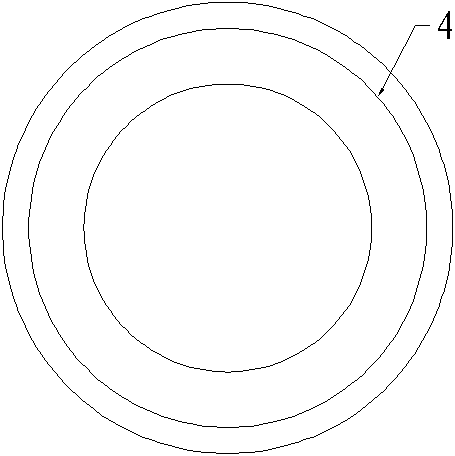

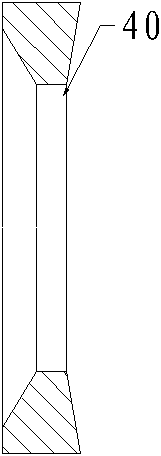

[0046] like Figure 1 to Figure 9 , Figure 11 ~ Figure 13 As shown, the compressed granulator of the present invention includes a power system 8 connected to the twin-screw extrusion feeding device in the machine head 1, a discharge cylinder 2 adapted to the twin-screw extrusion feeding device and the machine head 1 connection, the discharge cylinder 2 is arranged in sequence with a gathering tray 4, a flow diversion member 5 and an extrusion template 3 in contact with each other, wherein the extrusion template 3 is located at the outlet of the discharge cylinder 2, and the central hole 40 of the gathering tray 4 is Combination of tapered holes and round holes, the incoming side of the diverter part 5 is roughly conical, and six diverter ridges 52 are evenly distributed on the cone surface, and the diverter ridges 52 are provided with a gathering disk card that is compatible with the center hole 40 Between the opening 54 and the splitting ridge 52 is a fan-shaped splitting g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com