High-vacuum multi-station liquid adding system

A multi-station, high-vacuum technology, which is applied in the field of liquid filling system, can solve the problems of high product repair rate and reduced production capacity, and achieve the effect of reducing product failure and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

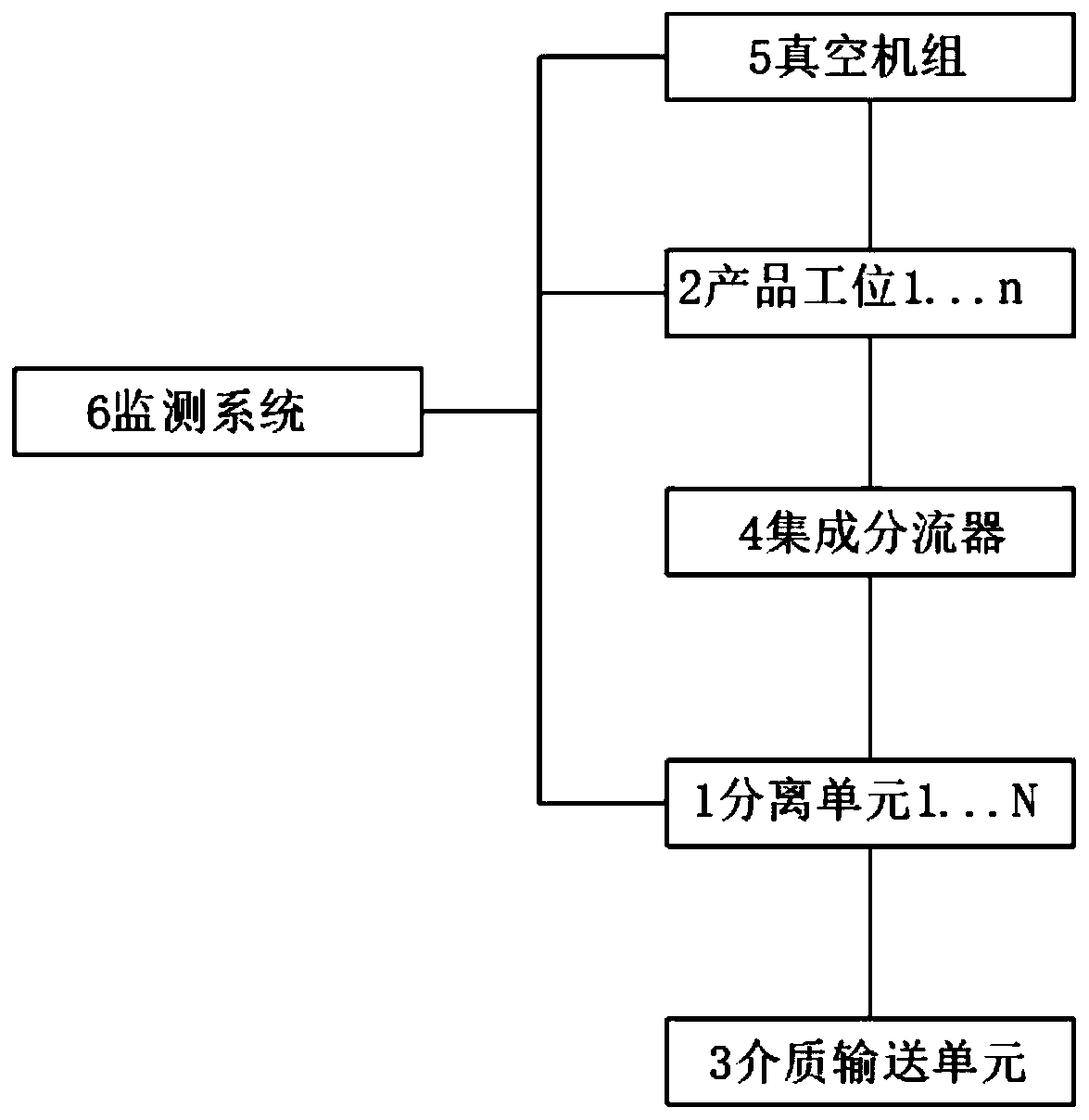

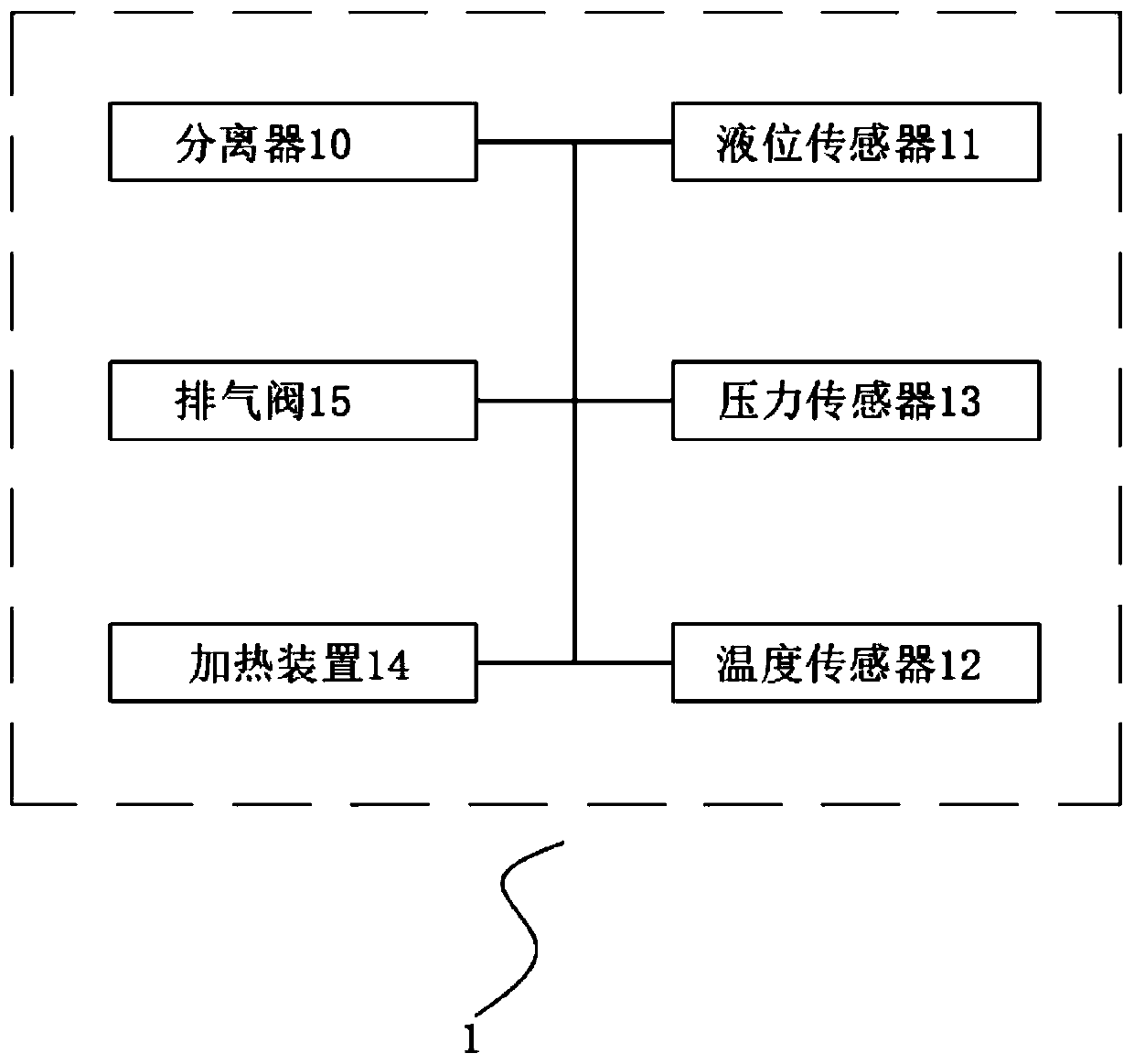

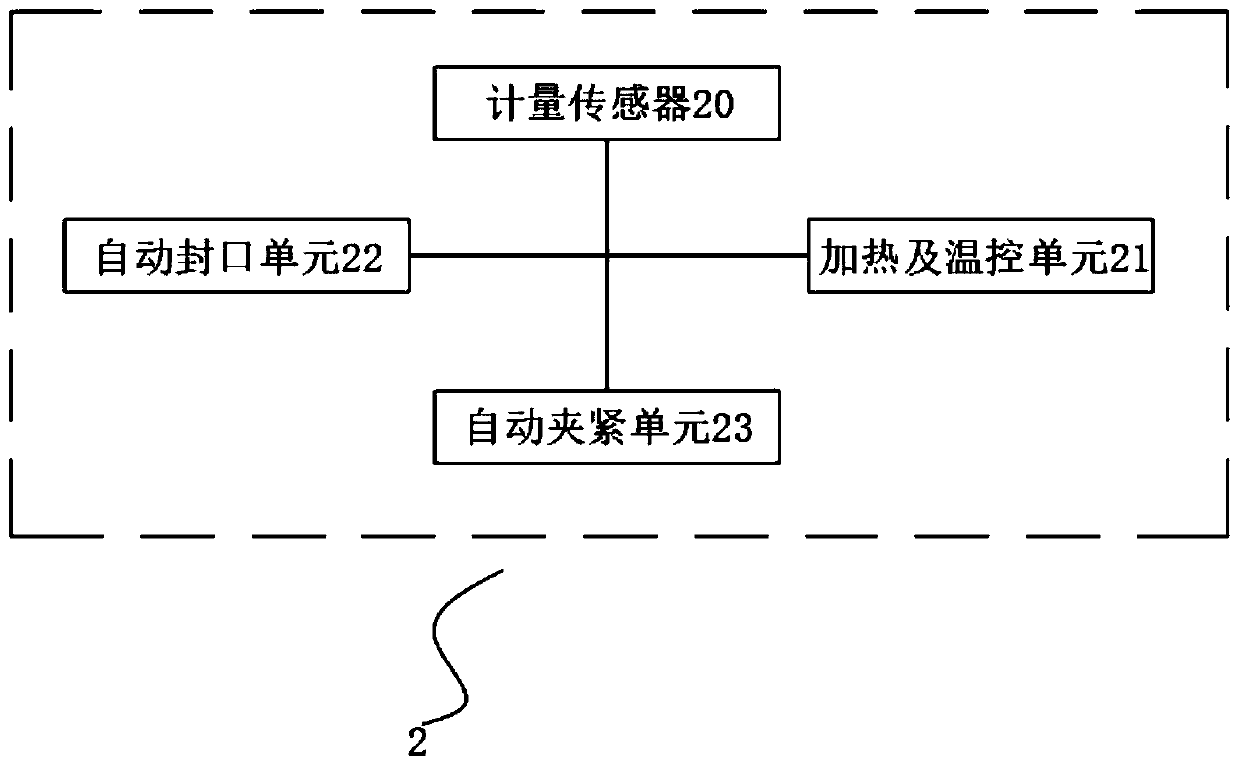

[0026] Such as Figure 1-4 As shown, the embodiment of the present invention provides a high-vacuum multi-station liquid adding system, including a separation unit 1, a product station 2, a medium conveying unit 3, an integrated splitter 4, a vacuum unit 5, a monitoring system 6, and a medium conveying unit 3 is connected to the separation unit 1 through the liquid inlet pipe, the separation unit 1 is connected to the integrated splitter 4 through the liquid outlet pipe, the integrated splitter 4 is connected to the product station 2 through the pipeline, and the vacuum unit 5 is connected to the product station through the pipeline 2 are connected, the number of product stations 2 and separation units 1 are multiple. The monitoring system 6 includes a control center 60, a vacuum monitoring unit 61, a filling monitoring unit 62, a separation monitoring unit 63, an automatic disconnect unit 64, and an alarm Unit 65, decision analysis unit 66.

[0027] The vacuum monitoring unit 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com