Wardrobe door plate machining method and machining equipment

A processing method and technology of processing equipment, which are applied in the field of wardrobe door panel processing methods and processing equipment, can solve the problems of long bonding time, health hazards, and incompatibility with water-based glue, and achieve shortened bonding time, enhanced work efficiency, and less failure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

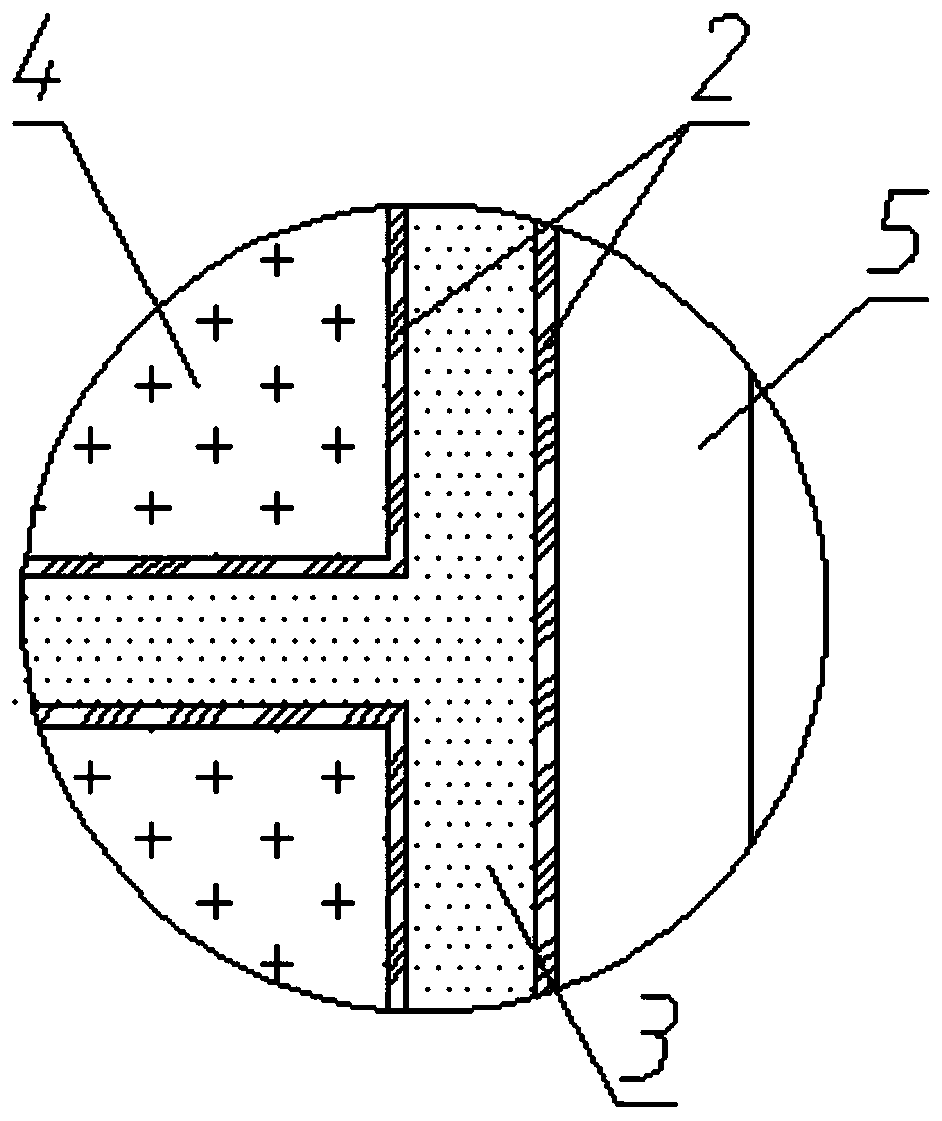

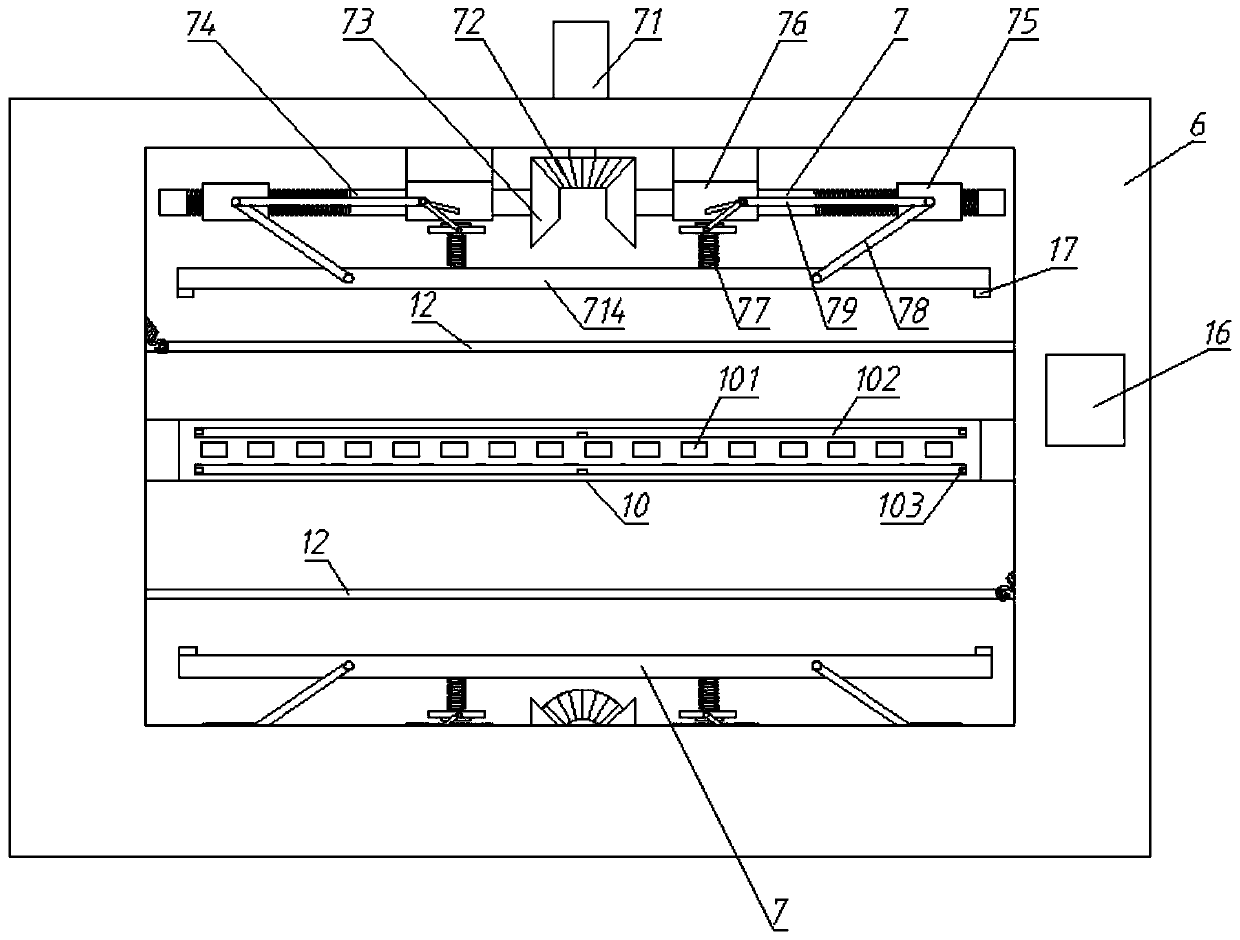

[0032] Wardrobe door panel processing methods, such as Figure 1 to Figure 10 As shown, the processed door panel 1 includes an outer frame 102, a belly plate 101 located inside the outer frame 102, and a wood veneer 5 arranged on the outer periphery of the outer frame 102, the end surface of the wood veneer 5 exceeds the outer frame 102 by a certain distance, The belly panel 101 and the skin 4 are manually bonded by water-based glue and put into the wardrobe door panel processing equipment. The skin 4 is preferably a microfiber leather, which is resistant to folding, has good leather, high strength and is environmentally friendly.

[0033] The door panel 1 includes a detachably connected belly plate 101 and an outer frame 102, the installation method is the same as that of the authorized announcement number CN209769565 U, by attaching the back plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com