Calophyllum inophyllum fruit beer and brewing method thereof

A technology of crabapple fruit and beer, which is applied in the field of beer brewing, can solve the problems of no crabapple fruit, beer body stability and flavor coordination, and achieve the effects of retaining flavor substances, increasing health care effects, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

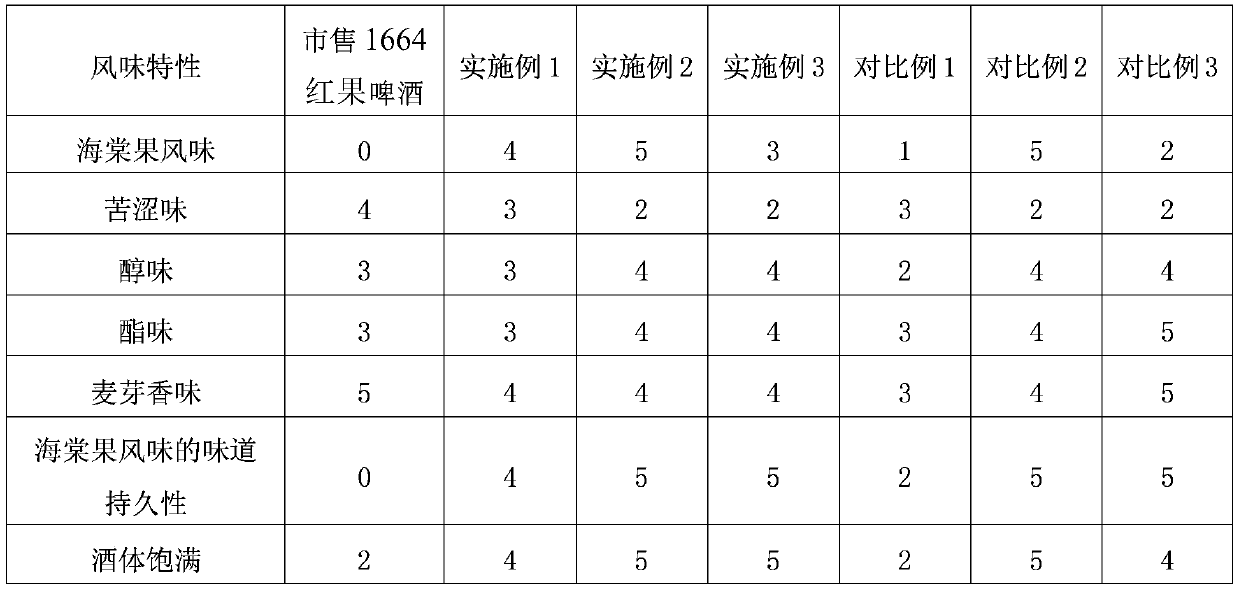

Examples

Embodiment 1

[0040] The crabapple beer comprises the following raw materials in weight percentage: 44% of pilsner malt, 1% of caramel malt, 45% of wheat malt and 10% of crabapple fruit juice.

[0041] The brewing method of above-mentioned crabapple beer comprises steps as follows:

[0042] (1) Select the crabapple fruit of medium maturity to peel and remove the core, squeeze the juice according to the mass ratio of material to water at 1:1, the water used for squeezing the juice is water that is cooled to room temperature from boiling water, and add pectinase in the squeezed juice, wherein , pectinase is obtained by dissolving pectinase solid powder in distilled water according to the mass ratio of 1:20, and the addition amount of pectinase is 0.01mL / L squeezed juice; Inactivate the enzyme in a water bath at 85°C for 15 minutes, then cool to room temperature, seal the crabapple fruit juice during the cooling period, and finally use a suction filter to obtain clarified crabapple fruit juice...

Embodiment 2

[0047] The crabapple beer comprises the following raw materials in weight percentage: 48% of pilsner malt, 2% of caramel malt, 30% of wheat malt and 20% of crabapple fruit juice.

[0048] The brewing method of above-mentioned crabapple beer comprises steps as follows:

[0049] (1) Select the crabapple fruit of medium maturity to peel and remove the core, squeeze the juice according to the mass ratio of material and water at 1:3, the water used for squeezing the juice is water that is cooled to room temperature in boiling water, and add pectinase in the squeezed juice, wherein , pectinase is obtained by dissolving pectinase solid powder in distilled water according to the mass ratio of 1:20. The amount of pectinase added is 0.01mL / L squeezed juice; Inactivate the enzyme in a water bath at 95°C for 15 minutes, then cool to room temperature, seal the crabapple fruit juice during the cooling period, and finally use a suction filter to obtain clarified crabapple fruit juice;

[00...

Embodiment 3

[0054] The crabapple beer comprises the following raw materials in weight percentage: 43% of pilsner malt, 2% of caramel malt, 25% of wheat malt and 30% of crabapple fruit juice.

[0055] The brewing method of above-mentioned crabapple beer comprises steps as follows:

[0056] (1) Select the crabapple fruit of medium maturity to peel and remove the core, squeeze the juice according to the mass ratio of material to water at 1:2, the water used for squeezing the juice is water from boiling water to room temperature, add pectinase in the squeezed juice, wherein , pectinase is obtained by dissolving pectinase solid powder in distilled water according to the mass ratio of 1:20, and the addition amount of pectinase is 0.01mL / L squeezed juice; Inactivate the enzyme in a water bath at 90°C for 15 minutes, then cool to room temperature, seal the crabapple fruit juice during the cooling period, and finally use a suction filter to obtain clarified crabapple fruit juice;

[0057] (2) Tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com