High-oil-absorption polypropylene material and preparation method thereof

A polypropylene material and high oil absorption technology, applied in the field of high oil absorption polypropylene material and its preparation, can solve the problems of unfavorable material recycling, increase material water absorption, increase material density, etc., achieve excellent floatability, facilitate recycling and disposal, The effect of high oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

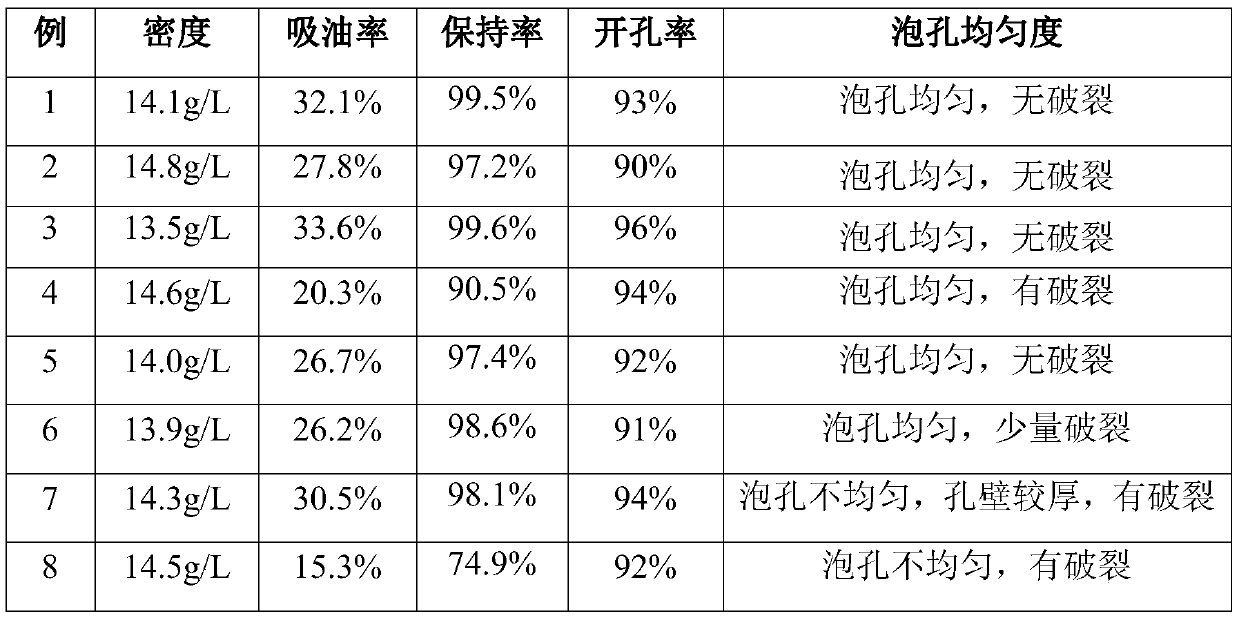

Examples

preparation example Construction

[0051] The preparation method of supercritical carbon dioxide in the present application can be any one known to those skilled in the art, such as pressurized extraction, or can be prepared using commercially available production equipment.

[0052] The inventor found in the research and development process that using supercritical carbon dioxide as a blowing agent greatly improves the foaming efficiency, and the cells are uniform and high in integrity. Rapid diffusion in the medium to form a polymer / gas homogeneous saturated system, and then produce a thermodynamic supersaturated state during mixing with other raw materials, causing phase separation of the system and triggering the formation and growth of bubble nuclei. In addition, the inventors have also found that supercritical carbon dioxide permeates into the polypropylene mobile phase, swelling the structure, increasing the distance between molecular chains, reducing the interfacial tension between the phases in the poly...

Embodiment 1

[0059] Embodiment 1 provides a kind of high oil-absorbing polypropylene material, by weight, its preparation raw material comprises:

[0060] 92 parts of polypropylene (PP9513 produced by ExxonMobil, whose melt index at 230°C and 2.16kg is 7.3g / 10min);

[0061] 6 parts of nucleating aids; the nucleating aids are polystyrene (GP5250 produced by Ningbo Taihua, the melt index at 200°C and 5kg load is 7g / 10min);

[0062] 4 parts of a phenyl-containing compound; the phenyl-containing compound is 1,3:2,4-bis(p-methylbenzylidene)sorbitol, CAS No.: 54686-97-4, purchased from Japan Mitsui Chemicals ;

[0063] 10 parts of whipping agent; Described whipping agent is supercritical carbon dioxide;

[0064] 2 parts of lipophilic additive; the lipophilic additive is hexadecyl pyridinium bromide.

[0065] This example also provides a preparation method of the above-mentioned high oil-absorbing polypropylene material, including the following steps: according to the proportion, polypropylene...

Embodiment 2

[0067] Embodiment 2 provides a kind of high oil absorption polypropylene material, by weight, its preparation raw material comprises:

[0068] 85 parts of polypropylene (PP9513 produced by ExxonMobil, whose melt index at 230°C and 2.16kg is 7.3g / 10min);

[0069] 2 parts of nucleating aid; said nucleating aid is polystyrene (GP5250 produced by Ningbo Taihua, the melt index at 200°C and 5kg load is 7g / 10min);

[0070] 1 part of a phenyl-containing compound; the phenyl-containing compound is 1,3:2,4-bis(p-methylbenzylidene)sorbitol, CAS No.: 54686-97-4, purchased from Japan Mitsui Chemicals ;

[0071] 5 parts of whipping agent; Described whipping agent is supercritical carbon dioxide;

[0072] 1 part of lipophilic additive; the lipophilic additive is hexadecyl pyridinium bromide.

[0073] This example also provides a preparation method of the above-mentioned high oil-absorbing polypropylene material, including the following steps: according to the proportion, polypropylene, nu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com