Multi-sulfo surfactant as well as preparation method and application thereof

A technology of surfactants and polysulfonic acid groups, which is applied in the direction of sulfonate preparation, carboxylic acid halide preparation, chemical instruments and methods, etc., and can solve the problem of insufficient surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

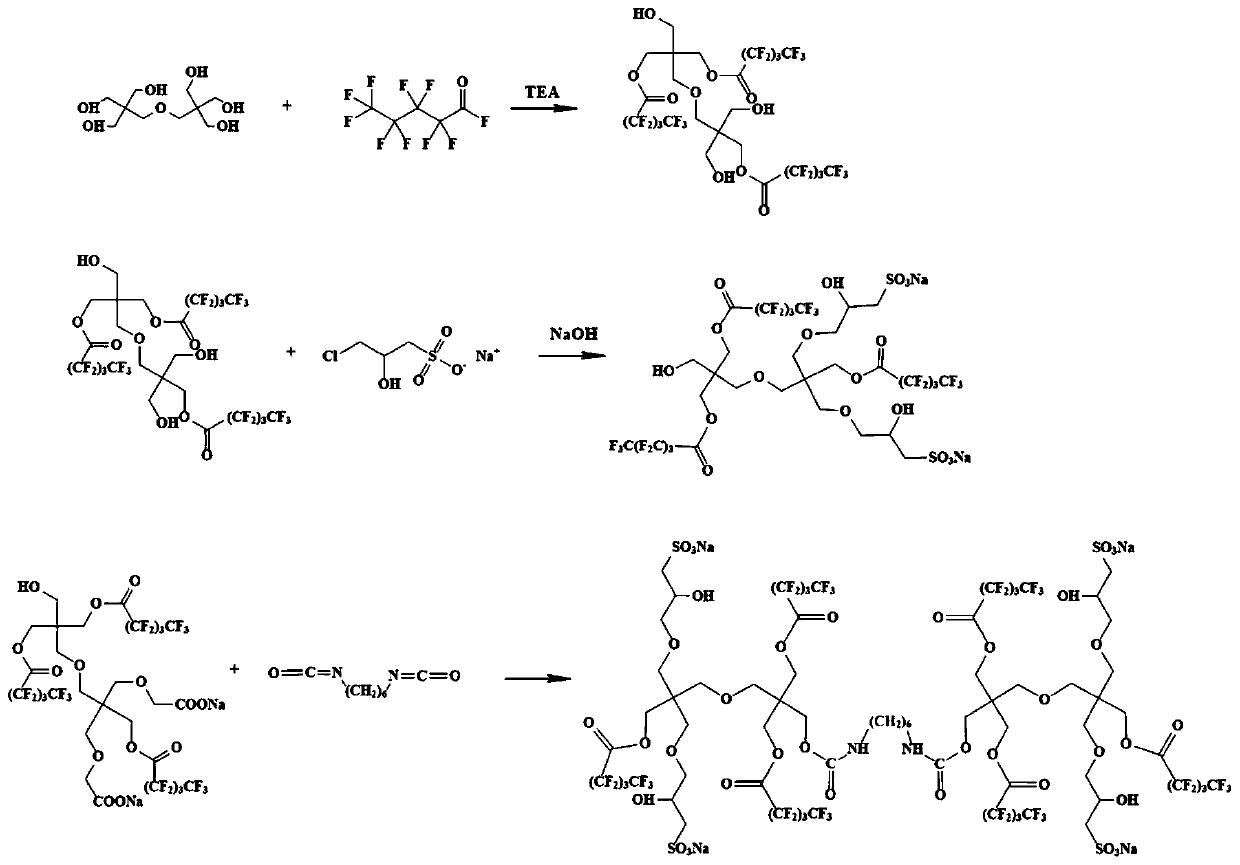

[0028] Concrete, a kind of preparation method of polysulfonic acid-based surfactant, comprises the following steps:

[0029] (1) Dissolve dipentaerythritol in dimethylformamide to obtain a dipentaerythritol solution, add triethylamine, stir and heat to 50-60°C, and add perfluorovaleryl fluoride dropwise while stirring. Wherein the molar ratio of dipentaerythritol to perfluorovaleryl fluoride is 1:(3-3.2). After the dropwise addition, continue to heat up to 75-85°C, and stir for 4-6 hours. The resulting product was first washed twice with 5% HCl solution, and then washed with 5% NaHCO 3 The solution was washed once, washed with water, extracted with ether, separated by liquid separation to obtain the upper organic layer, and the solvent was distilled off under reduced pressure to obtain a light yellow solid.

[0030] (2) Dissolve the light yellow solid obtained in step 1 in dimethyl sulfoxide (DMSO) and add it to a four-necked flask. After it is completely dissolved, add abou...

Embodiment 1

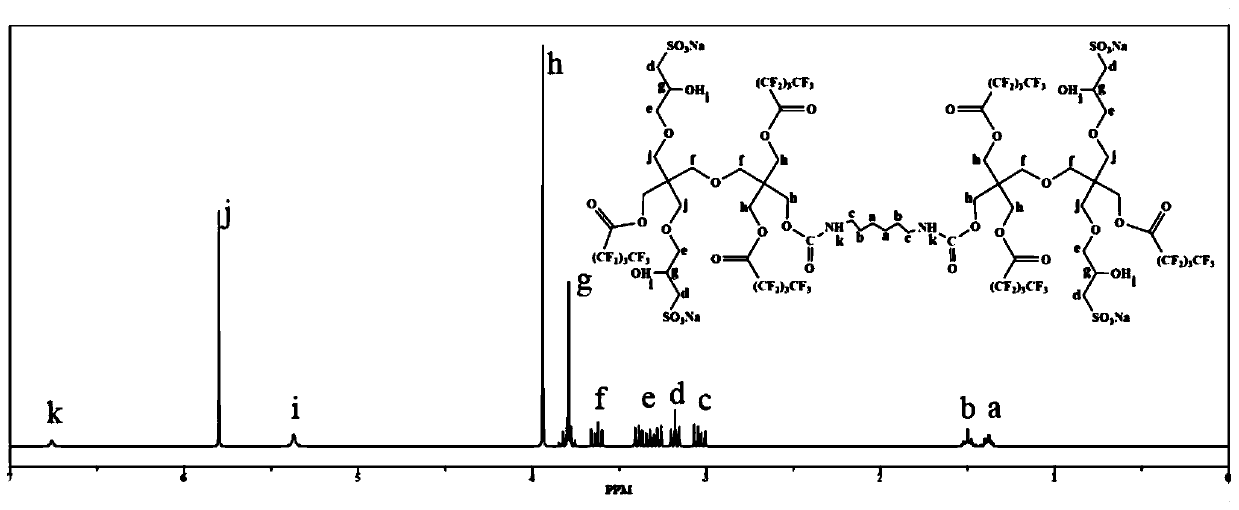

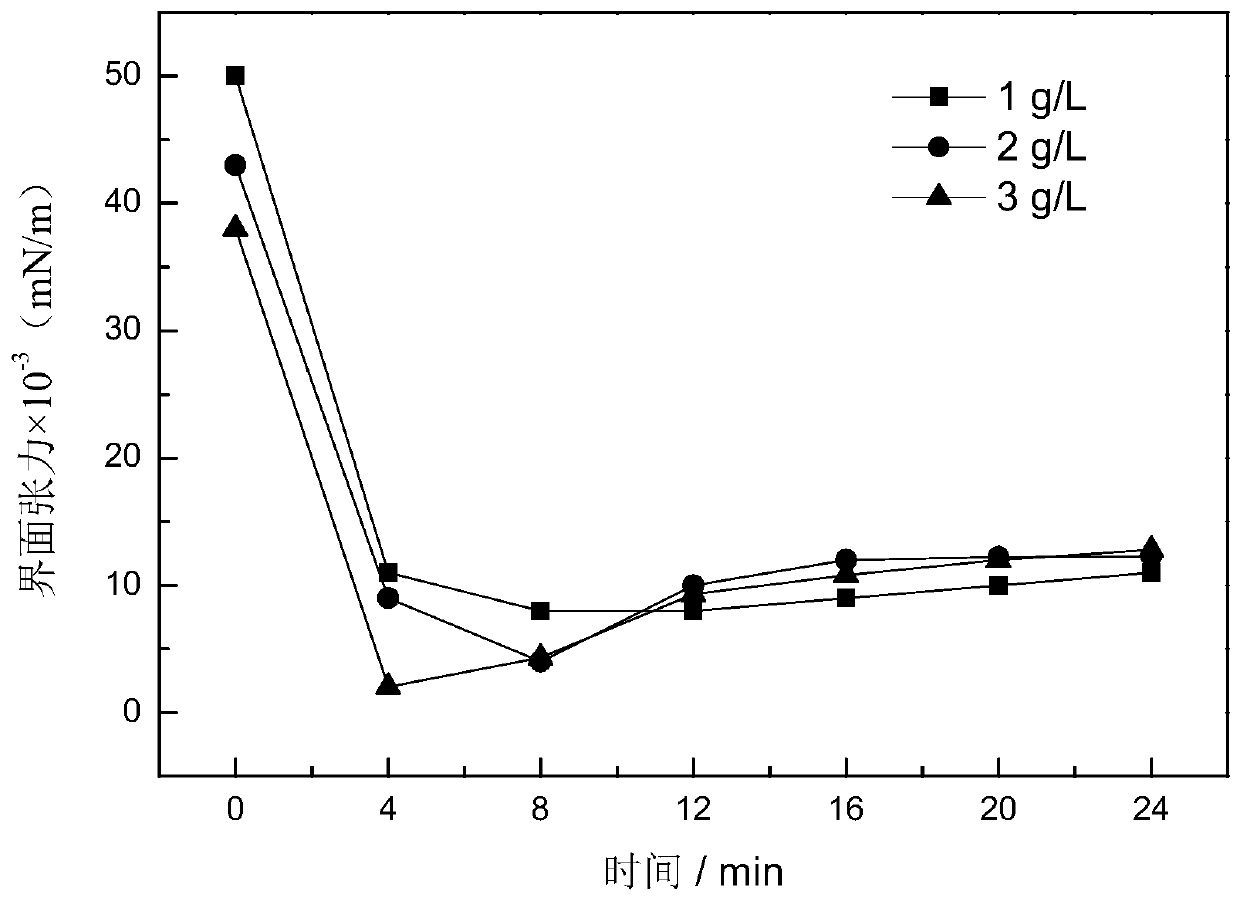

[0036] Equipped with a stirrer, thermometer, dropping funnel and reflux condenser (anhydrous CaCl 2 Drying tube) In a dry 250mL four-neck flask, dissolve dipentaerythritol in dimethylformamide to obtain a dipentaerythritol solution, add triethylamine and stir to heat to 55°C, then add perfluorovaleryl fluoride dropwise while stirring. The molar ratio of dipentaerythritol to perfluorovaleryl fluoride is 1:3. After the dropwise addition was completed, the temperature was continued to rise to 80° C., and the reaction was stirred for 5 h. The resulting product was first washed twice with 5% HCl solution, and then washed with 5% NaHCO 3 The solution was washed once, washed with water, extracted with ether, separated by liquid separation to obtain the upper organic layer, and the solvent was distilled off under reduced pressure to obtain a light yellow solid. Dissolve the obtained pale yellow solid in dimethyl sulfoxide (DMSO) and add it to a four-necked flask. After it is complet...

Embodiment 2

[0039] Equipped with a stirrer, thermometer, dropping funnel and reflux condenser (anhydrous CaCl 2 Drying tube) In a dry 250mL four-neck flask, dissolve dipentaerythritol in dimethylformamide to obtain a dipentaerythritol solution, add triethylamine and stir to heat to 55°C, then add perfluorovaleryl fluoride dropwise while stirring. The molar ratio of dipentaerythritol to perfluorovaleryl fluoride is 1:3. After the dropwise addition was completed, the temperature was continued to rise to 80° C., and the reaction was stirred for 5 h. The resulting product was first washed twice with 5% HCl solution, and then washed with 5% NaHCO 3 The solution was washed once, washed with water, extracted with ether, separated by liquid separation to obtain the upper organic layer, and the solvent was distilled off under reduced pressure to obtain a light yellow solid. Dissolve the obtained pale yellow solid in dimethyl sulfoxide (DMSO) and add it to a four-necked flask. After it is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com