Anesthesiology disinfection device

A disinfection device and anesthesiology technology, applied in the medical field, can solve the problems of low disinfection efficiency, poor device performance variability, increased operation energy consumption, etc., to ensure work efficiency and disinfection effect, increase disinfection effect and cleaning effect, and avoid electricity. Consumption and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

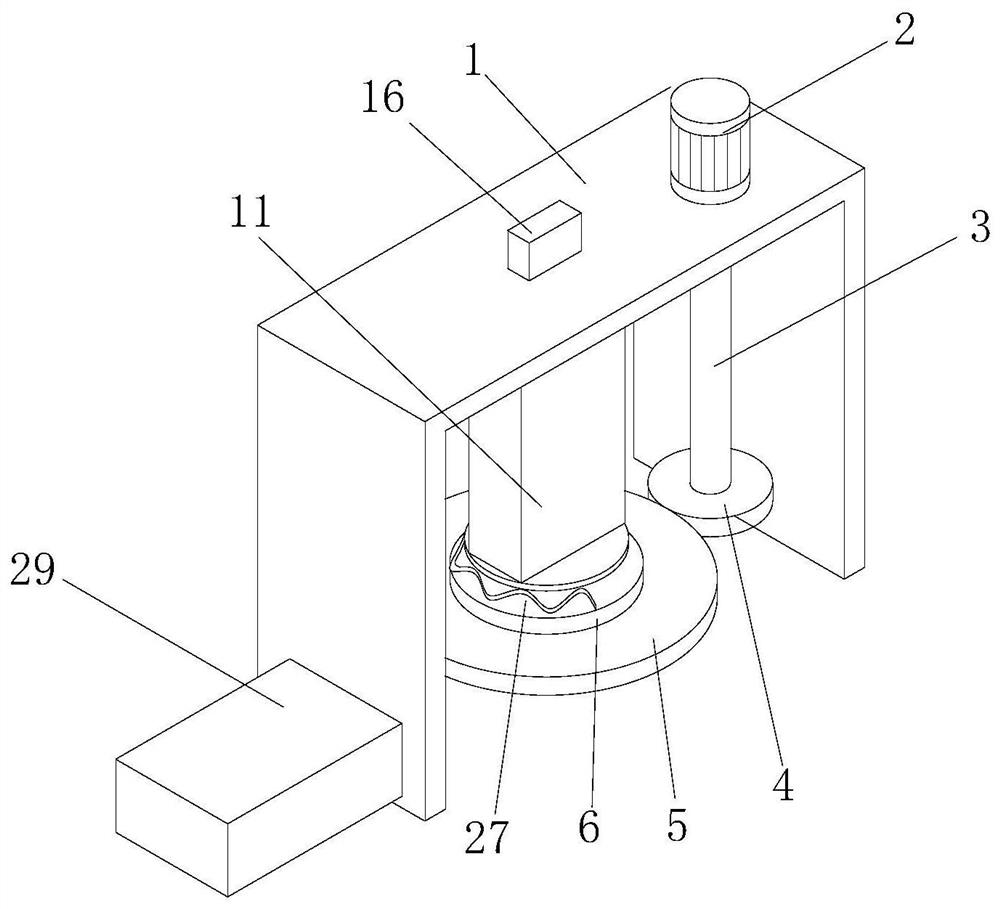

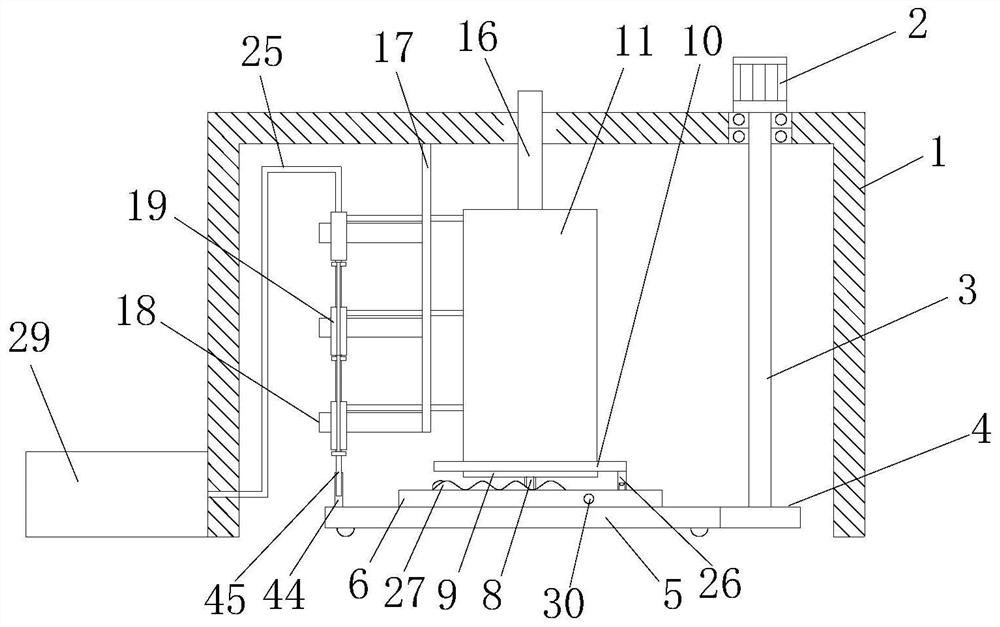

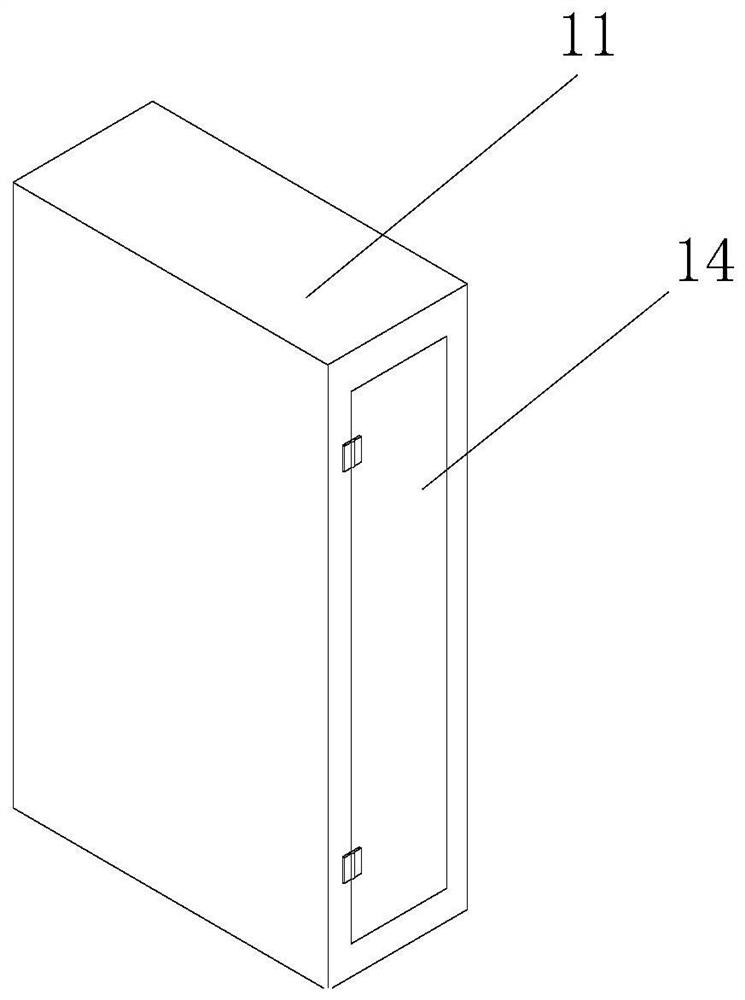

[0042] Example 1: Please refer to Figure 1-7 , an anesthesiology department disinfection device, comprising a frame 1 and a disinfection box 11, the frame 1 is a rectangular body hollowed out on the bottom surface, a rotating motor 2 is fixedly installed on the right side of the top surface of the frame 1, and the transmission shaft of the rotating motor 2 is located below the inner wall of the frame 1 and A transmission rod 3 is fixedly connected, and the end of the transmission rod 3 away from the rotating motor 2 is fixedly connected with a spur gear A4, and the left outer wall of the spur gear A4 is meshed with a chassis A5, and the chassis A5 is cylindrical and has tooth grooves on the outer wall. The top surface is fixedly connected with the chassis B6, and the center of the top surface of the chassis B6 is provided with a socket 7, which is a straight hole and penetrates through the chassis A5, and the inner wall of the socket 7 is sleeved with an insertion rod 8, and t...

Embodiment 2

[0045] Example 2: Please refer to Figure 8-10 , on the basis of Embodiment 1, the number of cylinders A19 on a single connection plate 18 is three and distributed left and right, the left side of the frame 1 is fixedly connected with the box body B40 and the box body C41, and the box body A29, the box body The body B40 and the box body C41 communicate with the round platform holes 22 at the top of the three cylinders A19 through connecting pipes 25 respectively. A groove is opened on the top surface of the chassis A5 and a telescopic motor 43 is fixedly installed in the groove. The transmission shaft of the telescopic motor 43 and the roller frame 44 is fixedly connected, and the telescopic motor 43 is fixedly installed with three sensors 42 in the slot installed on the chassis A5, and the three sensors 42 correspond to the positions of the three cylinders A19. Different disinfectants use the control circuit to control the expansion and contraction of the telescopic motor 43,...

Embodiment 3

[0047] Example 3: Please refer to Figure 11-14, On the basis of Embodiment 1, the corresponding clamp ring 13 positions on the left side of the disinfection tank 12 are provided with a discharge groove 55, and the shape of the discharge groove 55 is oblique rectangle (such as Figure 13 As shown), the position corresponding to the clamp ring 13 on the right side of the disinfection tank 12 is provided with a feed tank 54. Be positioned at disinfection box 11 fronts (as Figure 14 shown), the right side of the disinfection box 11 is provided with a movable groove 47 above the disinfection groove 12, the center inner wall of the movable groove 47 is fixedly connected with a slide bar 48, and the outer wall of the slide bar 48 is sleeved with a sleeve 49, and the sleeve 49 The bottom surface of the sleeve 49 is fixedly connected with a return spring A50, and the end of the return spring A50 away from the sleeve 49 is fixedly connected with the bottom surface of the movable groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com