A method for preparing a high-reliability and high-density integrated structure of a power device

A power device and high-density technology, which is applied in the preparation of high-reliability and high-density integrated structures of power devices, and the field of high-reliability three-dimensional assembly of power devices, can solve the difficulties of integrating broadband high-frequency circuits, excessive differences in thermal expansion coefficients, and wide range of applications. Limitations and other issues to achieve the effect of ensuring three-dimensional high-density integration and efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

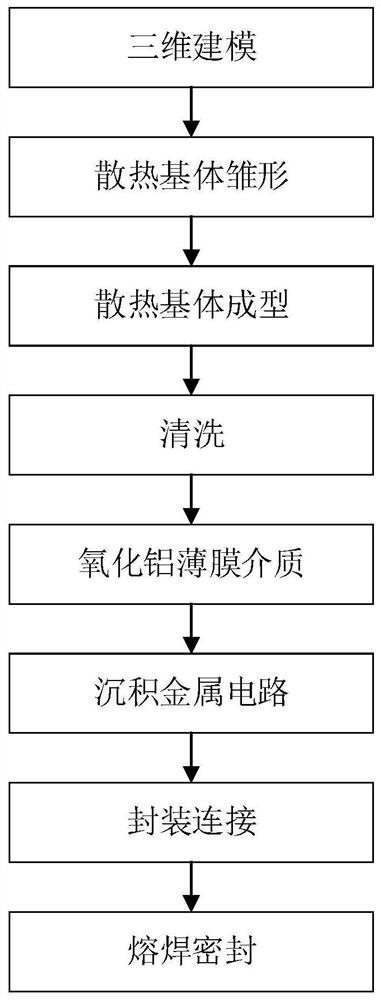

[0044] Such as figure 1 As shown, a method for preparing a high-reliability and high-density integrated structure of a power device of the present invention comprises the following steps:

[0045] S1, drawing a three-dimensional model of the integrated structure of power devices;

[0046] S2, use the gradient material to make the prototype of the heat dissipation matrix according to the three-dimensional model;

[0047] S3, using precision machining to shape the prototype of the heat dissipation substrate;

[0048] S4, cleaning the formed heat dissipation substrate;

[0049] S5, forming a layer of aluminum oxide film on the required position on the surface of the heat dissipation substrate;

[0050] S6, depositing a metal circuit on the surface of the aluminum oxide film;

[0051] S7, connect the bare chip, micro-module and packaging unit to the designated area on the surface of the heat dissipation substrate;

[0052] S8, sealing the outer cover of the power device and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com