Preparation method for cerium oxide nanorod array/graphene composite material and application of cerium oxide nanorod array/graphene composite material in photocathode protection

A technology of nanorod arrays and composite materials, applied in the field of preparation of cerium oxide nanorod arrays/graphene composite materials, can solve the problem that cerium oxide nanoparticles cannot conduct electrons quickly and effectively, so as to promote directional transmission and improve light absorption Efficiency, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

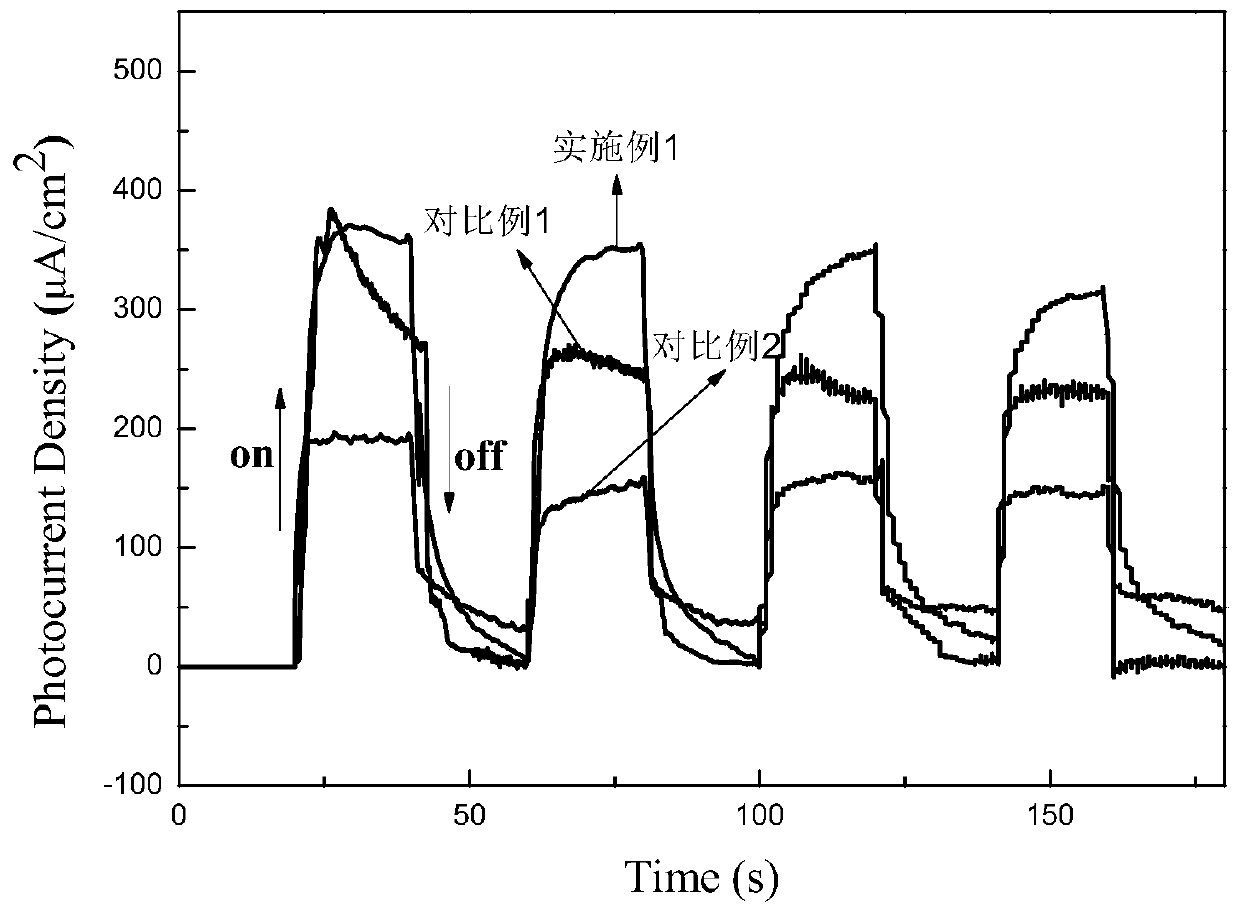

Embodiment 1

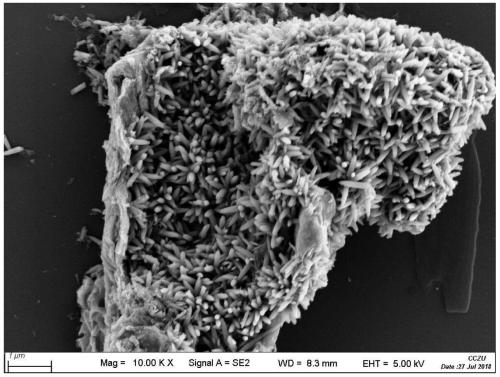

[0021] 1. With 0.01mol / L cerium nitrate as electrolyte, 0.05mol / L potassium chloride as auxiliary electrolyte, 0.1mol / L ammonium chloride as stabilizer, the ratio of the amount of cerium nitrate to ammonium chloride 1:2, the ratio of cerium nitrate to potassium chloride is 1:0.1, Ti is the substrate, Pt is the counter electrode, and the saturated Ag / AgCl electrode is the reference electrode, at 50°C, 0.5mA / cm 2 Potential deposition at a current density of 80min, in CeO 2 Nucleation and growth of CeO on the seed layer 2 nanorod arrays.

[0022] 2. Prepare 50mL of 0.025mol / L SnCl 2 ethanol solution to activate CeO 2 Nanorod array, weigh a certain amount of graphite oxide and dissolve it in 100mL deionized water, and the activated CeO 2 Nanorod arrays were immersed in graphite oxide solution and stirred at 50 °C for 0.5 h, followed by Na 2 SO 4 Rinse with deionized water, and dry in vacuum at 50°C to obtain a ceria nanorod array / graphene composite.

Embodiment 2

[0024] 1. With 0.03mol / L cerium ammonium nitrate as electrolyte, 0.20mol / L potassium chloride as auxiliary electrolyte, 0.3mol / L ammonium acetate as stabilizer, the ratio of the amount of cerium ammonium nitrate to ammonium acetate 1:1, the ratio of cerium ammonium nitrate to potassium chloride is 1:5, ITO conductive glass is the substrate, Pt is the counter electrode, and the saturated Ag / AgCl electrode is the reference electrode, at 70°C, 3mA / cm 2 CeO was grown on the seed layer by potential deposition at a current density of 120 min 2 nanorod arrays.

[0025] 2. Prepare 100mL of 0.05mol / L SnCl 2 ethanol solution to activate CeO 2 Nanorod array, weigh a certain amount of graphite oxide and dissolve it in 200mL deionized water, and the activated CeO 2 Nanorod arrays were immersed in graphite oxide solution and stirred at 70 °C for 2 h, followed by Na 2 SO 4 Rinse with deionized water, and dry in vacuum at 70°C to obtain cerium oxide nanorod arrays / graphene composites. ...

Embodiment 3

[0027] 1. With 0.05mol / L ammonium chloride as electrolyte, 0.35mol / L potassium chloride as auxiliary electrolyte, 0.5mol / L hexamethylenetetramine as stabilizer, ammonium chloride and hexamethylene The ratio of the substance amount of tetramine is 1:0.5, the ratio of the substance amount of ammonium chloride to potassium chloride is 1:10, the FTO conductive glass is the substrate, Pt is the counter electrode, and the saturated Ag / AgCl electrode is the reference electrode. Specific electrode, at 90°C, 5.5mA / cm 2 CeO was grown on the seed layer by potential deposition at a current density of 160 min 2 nanorod arrays.

[0028] 2. Prepare 150mL of 0.075mol / L SnCl 2 ethanol solution to activate CeO 2 nanorod array, weigh a certain amount of graphite oxide and dissolve it in 300mL deionized water, and the activated CeO 2 The nanorod arrays were immersed in graphite oxide solution and stirred at 90 °C for 3.5 h, followed by Na 2 SO 4Rinse with deionized water, and dry in vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com