Biomass nanocellulose/polypyrrole composite aerogel, and preparation method and application thereof

A technology of nanocellulose and composite airgel, which is applied in the direction of airgel preparation, organic material conductor, chemical instrument and method, etc., can solve the problems of limited application, and achieve the advantages of simple operation, good conductivity, and easy control of conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a preparation method of the biomass nanocellulose / polypyrrole composite aerogel described in the above scheme, which includes the following steps:

[0030] (1) Prepare the biomass material into an aqueous nanocellulose suspension;

[0031] (2) Injecting an aqueous solution of ammonium persulfate into the nanocellulose aqueous suspension, and letting it stand for 1.5 to 2 hours for solvent replacement to obtain nanocellulose hydrogel;

[0032] (3) Soak the nanocellulose hydrogel in a phytic acid solution of pyrrole, and let it stand for 2-12 hours to obtain a nanocellulose / polypyrrole composite hydrogel;

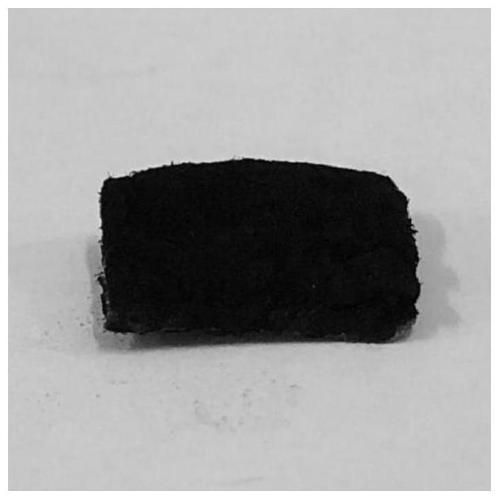

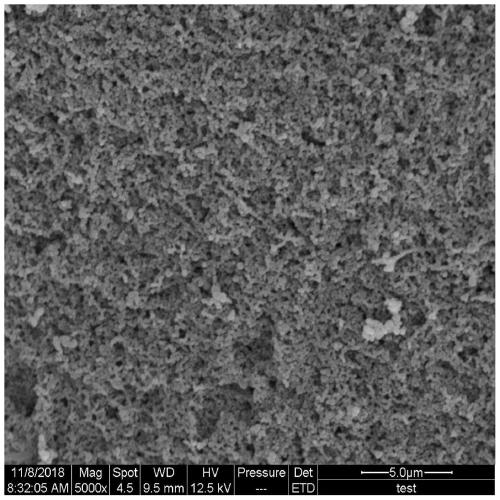

[0033] (4) freeze-drying the nanocellulose / polypyrrole composite hydrogel to obtain the biomass nanocellulose / polypyrrole composite aerogel.

[0034] The invention prepares the biomass material into an aqueous nano-cellulose suspension. The present invention does not have special requirements for the biomass material, and it is sufficient to use b...

Embodiment 1

[0054] (1) Add 30g of poplar wood powder to 1500g of distilled water, then add 15g of sodium chlorite and 2mL of glacial acetic acid, cover the beaker with plastic wrap, and heat in a constant temperature water bath at 75°C for 1 hour; add sodium chlorite and ice above. The operation of acetic acid and water bath heating was repeated 6 times to clean the sample to neutrality; then put the sample into 800g potassium hydroxide solution with a mass fraction of 5%, and directly heat it in a constant temperature water bath at 90°C for 2h, and wash it to neutrality. Suction and filter excess water to obtain purified cellulose in a hydrated state;

[0055] (2) Prepared from purified cellulose into 0.5wt% aqueous solution;

[0056] (3) The purified cellulose aqueous solution was subjected to ultrasonic treatment with a power of 1200W and a treatment time of 30min, and then continued high-pressure homogenization treatment, the treatment time was 20min, the primary pressure was 40-90bar, and...

Embodiment 2

[0062] (1) Add 30g of poplar wood powder to 1500g of distilled water, then add 15g of sodium chlorite and 2mL of glacial acetic acid, cover the beaker with plastic wrap, and heat in a constant temperature water bath at 75°C for 1 hour; add sodium chlorite and ice above. The operation of acetic acid and water bath heating was repeated 6 times to clean the sample to neutrality; then put the sample into 800g potassium hydroxide solution with a mass fraction of 5%, and directly heat it in a constant temperature water bath at 90°C for 2h, and wash it to neutrality. Suction and filter excess water to obtain purified cellulose in a hydrated state;

[0063] (2) Prepared from purified cellulose into 0.8%wt concentration aqueous solution;

[0064] (3) The purified cellulose aqueous solution was subjected to ultrasonic treatment with a power of 1200W and a treatment time of 30min, and then continued high-pressure homogenization treatment, the treatment time was 20min, the primary pressure was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com