A method for preparing high-purity ultrafine zirconium boride powder by grinding aid-assisted sand milling

A grinding aid, zirconium boride technology, applied in the field of zirconium boride powder preparation, can solve the problem that the particle size, purity and output of zirconium boride powder cannot meet scientific research and production, long production cycle and other problems, and achieve enhanced sintering. The effect of driving force, short production cycle and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] (1) In step A, the amount of oleic acid used is 1-20% of the total volume of the clear solution.

[0037] (2) In step C, the grinding into powder is to perform ball milling on the dried zirconium boride precursor gel, the ball milling speed is 50-400rpm, and the ball milling time is 0.5-4h, so that the dried boride Zirconium precursor gel changed from block to powder.

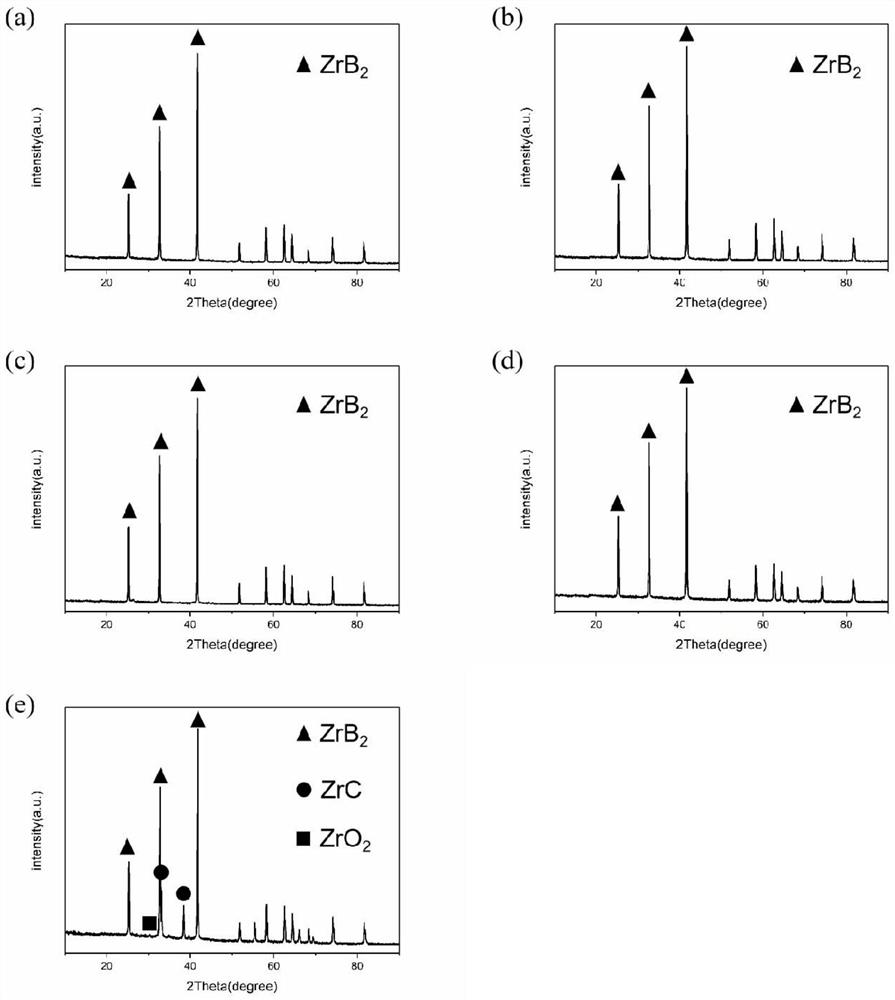

[0038] (3) In step C, the calcination uses high-purity argon (Ar ≥ 99.999%) as a protective gas, and the debinding furnace is heated from room temperature to 400-600°C at a rate of 1-5°C / min , keep warm for 10-120 minutes, then raise the temperature to 600-800 ℃ at a rate of 1-5 ℃ / min, keep warm for 10-120 minutes, and then cool naturally to room temperature. This calcination process can remove the organic matter in the zirconium boride precursor gel powder, making the subsequent high-temperature calcination products more uniform.

[0039](4) In step D, the grinding aid is a chlorine-containing organic...

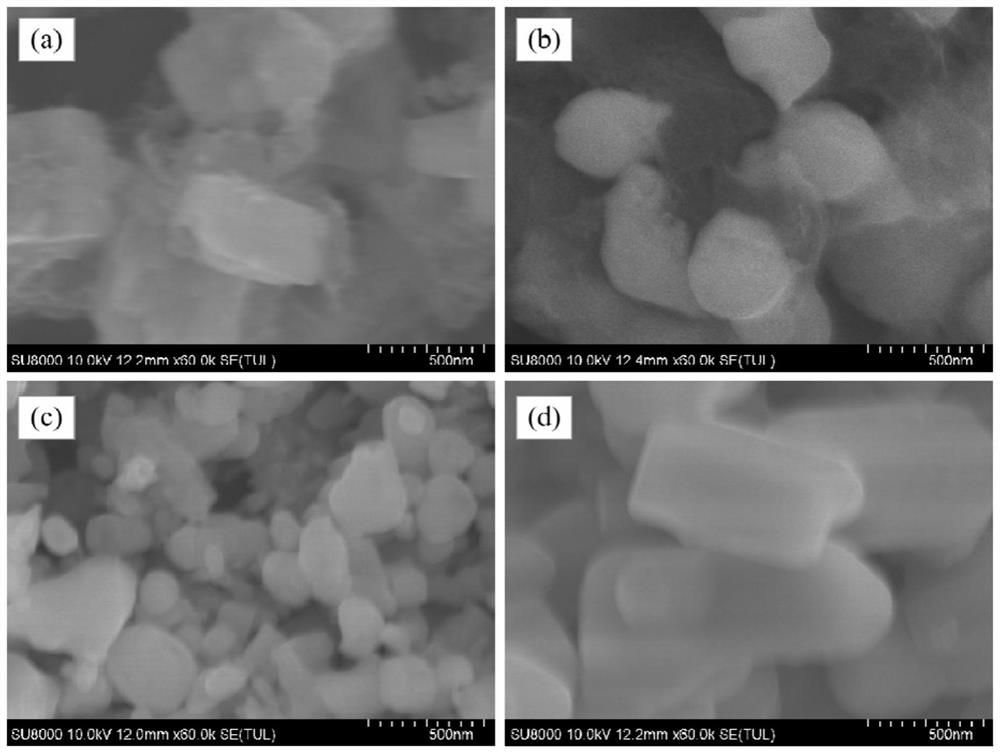

Embodiment 1

[0051] A method for preparing high-purity ultrafine zirconium boride powder by grinding aid-assisted sand milling may include the following steps:

[0052] Step a1. Weigh 3.875g of boric acid and 6.875g of sorbitol, put them into the same beaker and mix them, then pour 30mL of acetic acid (analytical pure) into it, and use an oil bath magnetic stirrer to gradually raise the temperature to 60°C, and stir at a constant temperature , until the boric acid and sorbitol are completely dissolved in acetic acid, and the solution is completely clear, thereby obtaining a clear solution. Add 0.6mL oleic acid to the clarified solution, stop heating, continue to stir until cooled to room temperature, and then slowly drop in 9.375mL zirconium n-propoxide at a constant speed of 0.5-10mL / min under continuous stirring (with time 10 min), thereby preparing the zirconium boride precursor sol.

[0053] Step b1, sealing the zirconium boride precursor sol, putting it into a constant temperature bo...

Embodiment 2

[0058] A method for preparing high-purity ultrafine zirconium boride powder by grinding aid-assisted sand milling may include the following steps:

[0059] Step a2, weigh 3.875g of boric acid and 6.875g of sorbitol, put them into the same beaker and mix them, then pour 30mL of acetic acid (analytical pure) into it, and use an oil bath magnetic stirrer to gradually raise the temperature to 60°C, and stir at a constant temperature , until the boric acid and sorbitol are completely dissolved in acetic acid, and the solution is completely clear, thereby obtaining a clear solution. Add 0.6mL oleic acid to the clarified solution, stop heating, continue to stir until cooled to room temperature, and then slowly drop in 9.375mL zirconium n-propoxide at a constant speed of 0.5-10mL / min under continuous stirring (with time 10 min), thereby preparing the zirconium boride precursor sol.

[0060] Step b2, sealing the zirconium boride precursor sol, putting it into a constant temperature bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com