Improved TP + LCM full-fit system and control method

A full lamination, conveyor belt technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

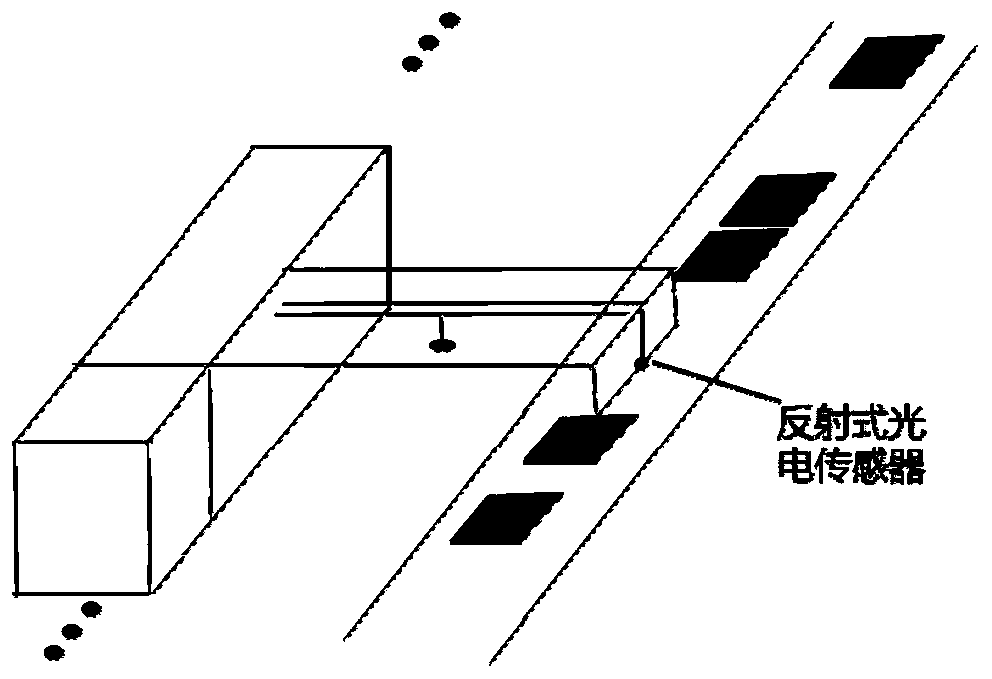

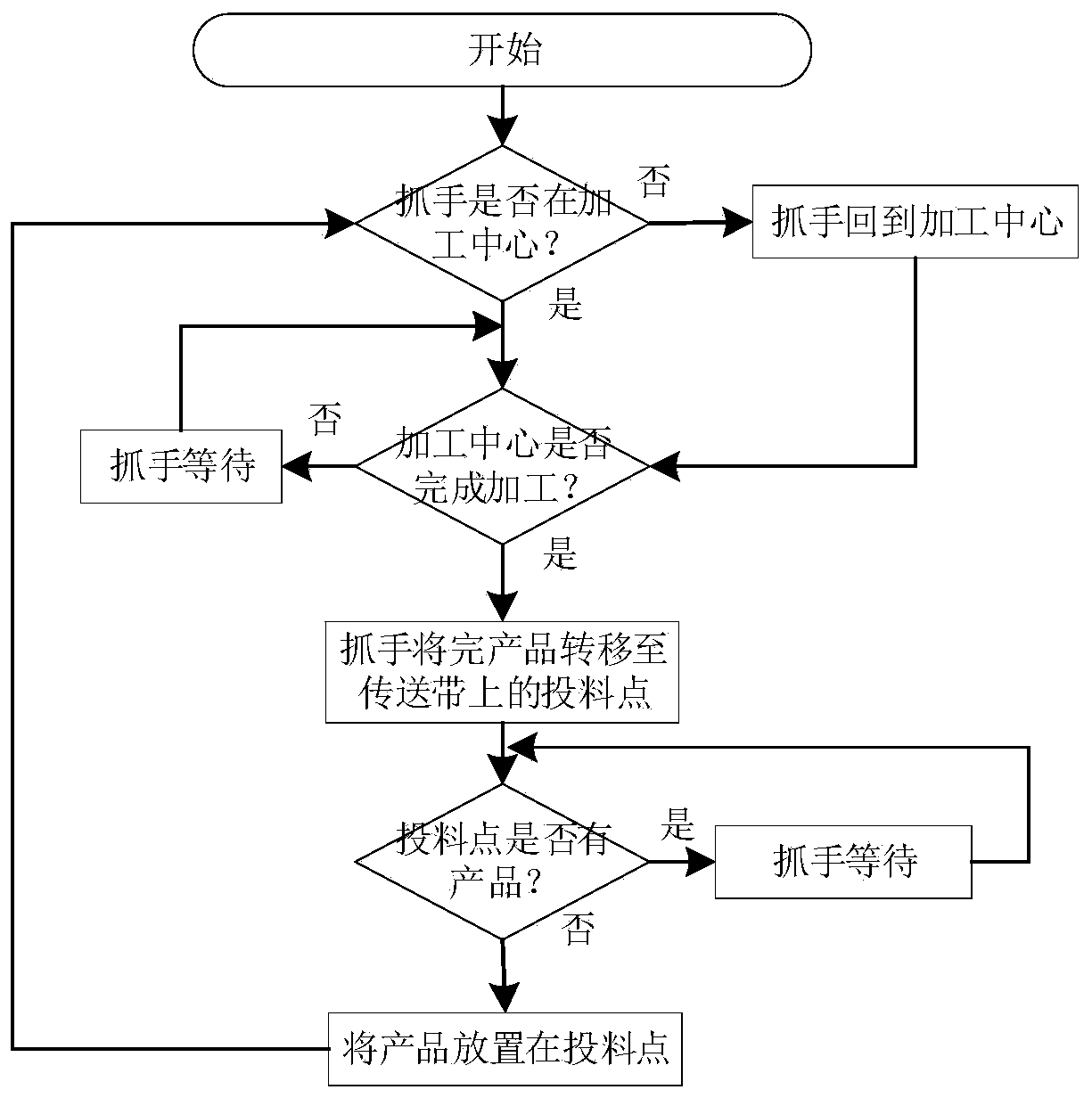

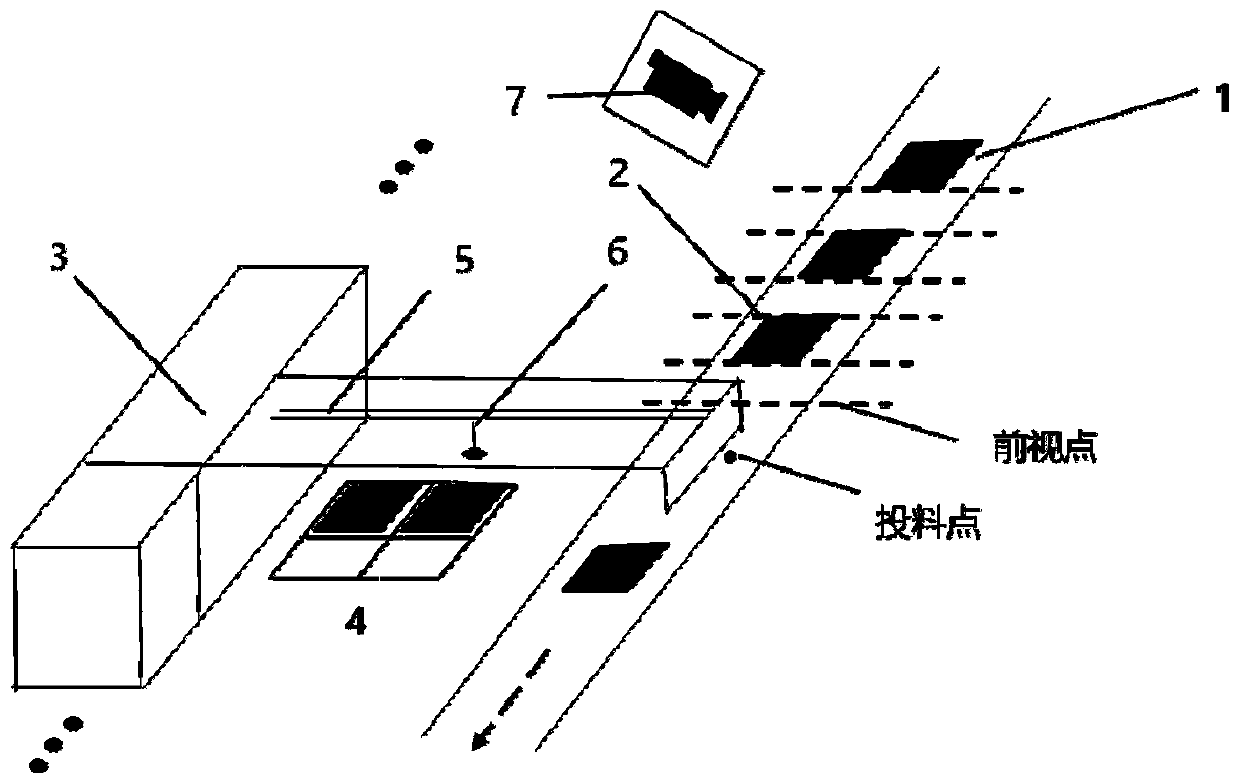

[0097] see image 3 , an improved TP+LCM full lamination system, including: a conveyor belt 2 moving at a constant speed, several processing stations, TLCM1 with the same size after lamination are randomly distributed on the conveyor belt 2 moving at a uniform speed, each of the The station includes a processing center 3 located on one side of the conveyor belt 2, a buffer storehouse 4 with a capacity of M, a guide rail 5, a gripper 6, a front-view sensor 7 and a feeding point;

[0098] A guide rail 5 is arranged between the machining center 3 and the conveyor belt 2, and the gripper 6 is located on the guide rail 5 and moves between the machining center 3 and the conveyor belt 2 along the guide rail 5 for transferring materials ; The buffer storehouse 4 is arranged below the guide rail 5 for temporarily storing the TLCM1 to be thrown after processing; the forward-looking sensor 7 is located upstream of the processing center 3 and is used to obtain the upstream conveyor belt o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com