Surface treatment method for high strength bolt

A high-strength bolt and surface treatment technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as low work efficiency, difficult operation, cumbersome steps of bolt surface treatment methods, etc., to achieve The steps are simple, easy to operate, and the processing effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

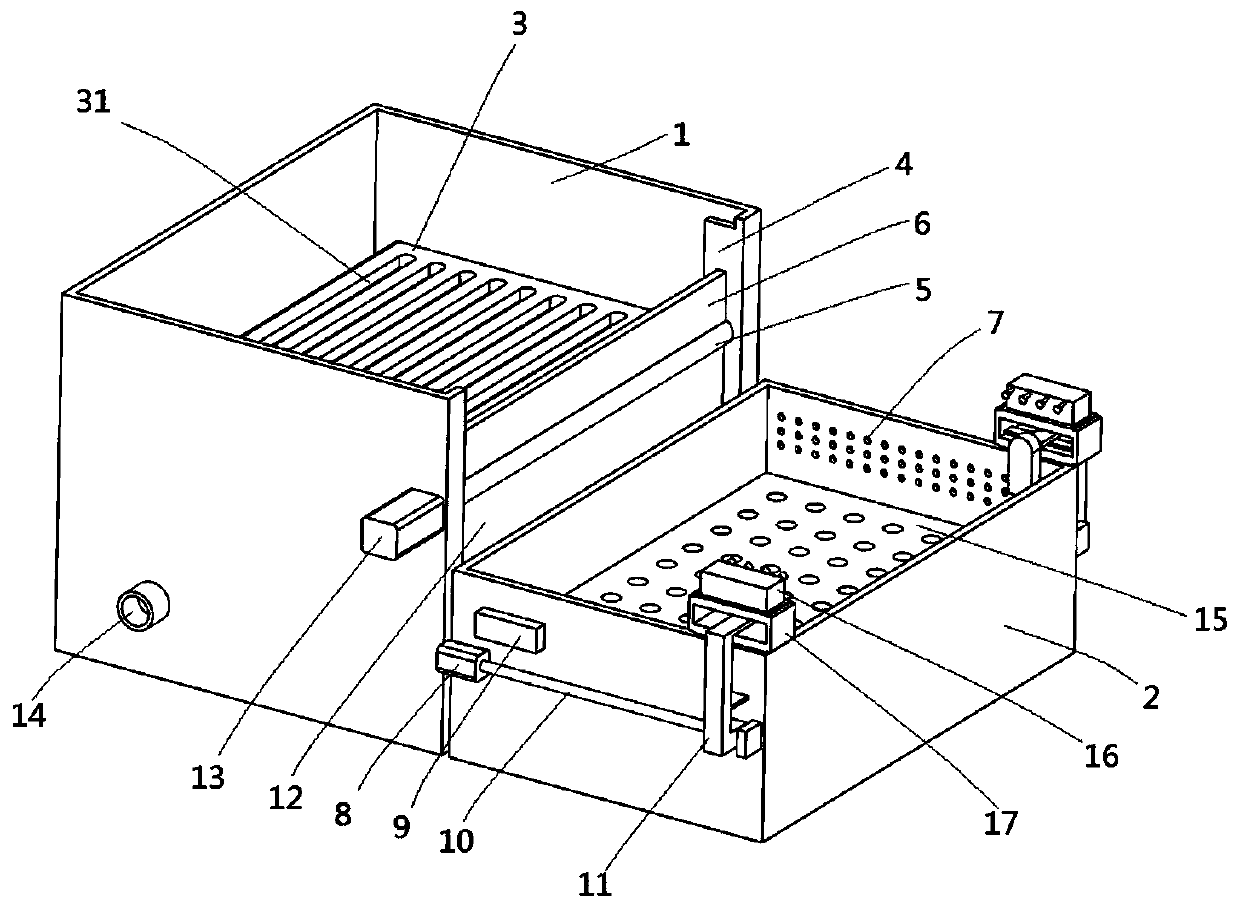

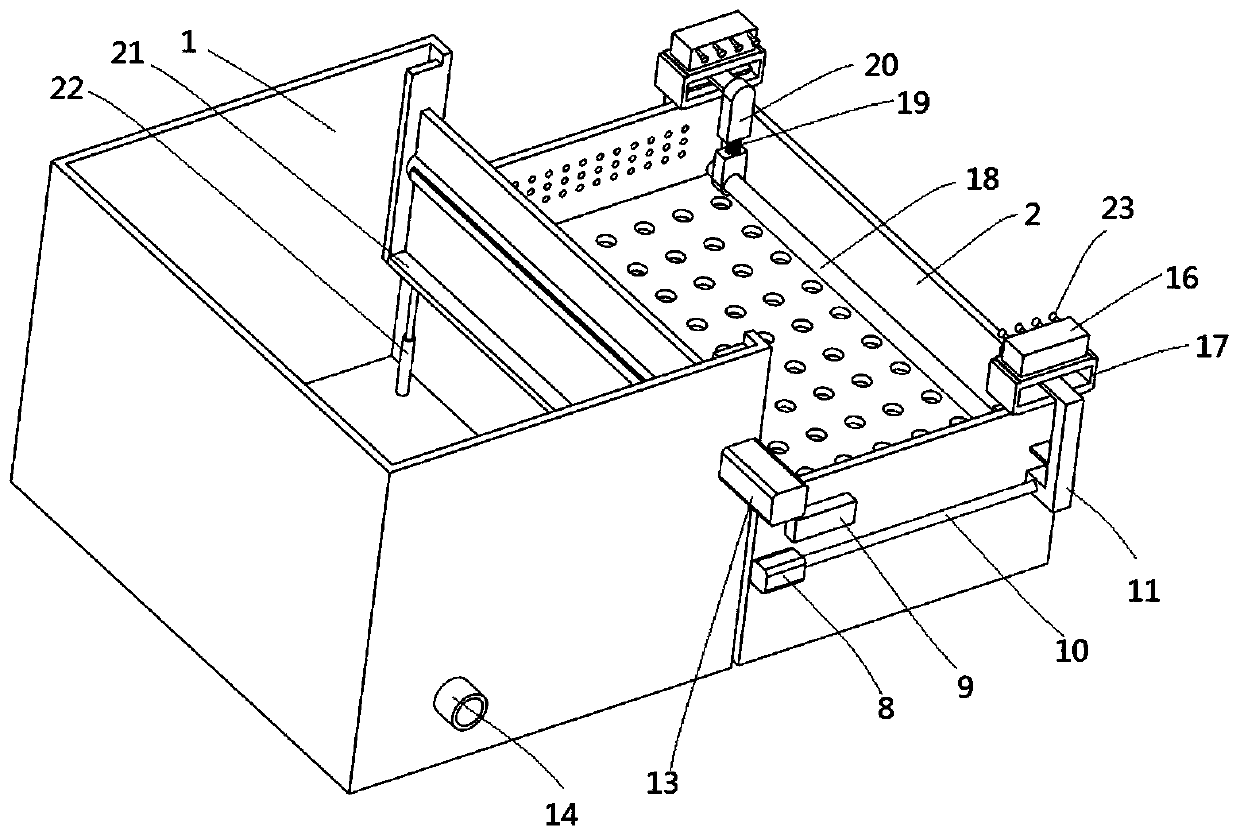

[0033] see Figure 1-4 , an ultrasonic cleaning device, comprising an ultrasonic cleaning machine, the ultrasonic cleaning machine includes a cleaning box 1 and a collection box 2 adjacently arranged, the cleaning box 1 is provided with an ultrasonic cleaning device, and the ultrasonic transducer in the ultrasonic cleaning device is placed in the cleaning box 1, so as to carry out ultrasonic cleaning, the side of the cleaning box 1 close to the collection box 2 is provided with a rectangular opening, and the opposite sides of the opening are all vertically fixed side plates 4 inward, and the middle part of the opening is rotated to install a horizontal shaft 5 , the cleaning box 1 is also provided with a sealing mechanism for sealing the rotating shaft 5 and the open bottom surface, and the outer wall of the cleaning box 1 is fixed with a first motor 13, and the output shaft of the first motor 13 is drivingly connected with the rotating shaft 5 for driving the rotating shaft 5...

Embodiment 2

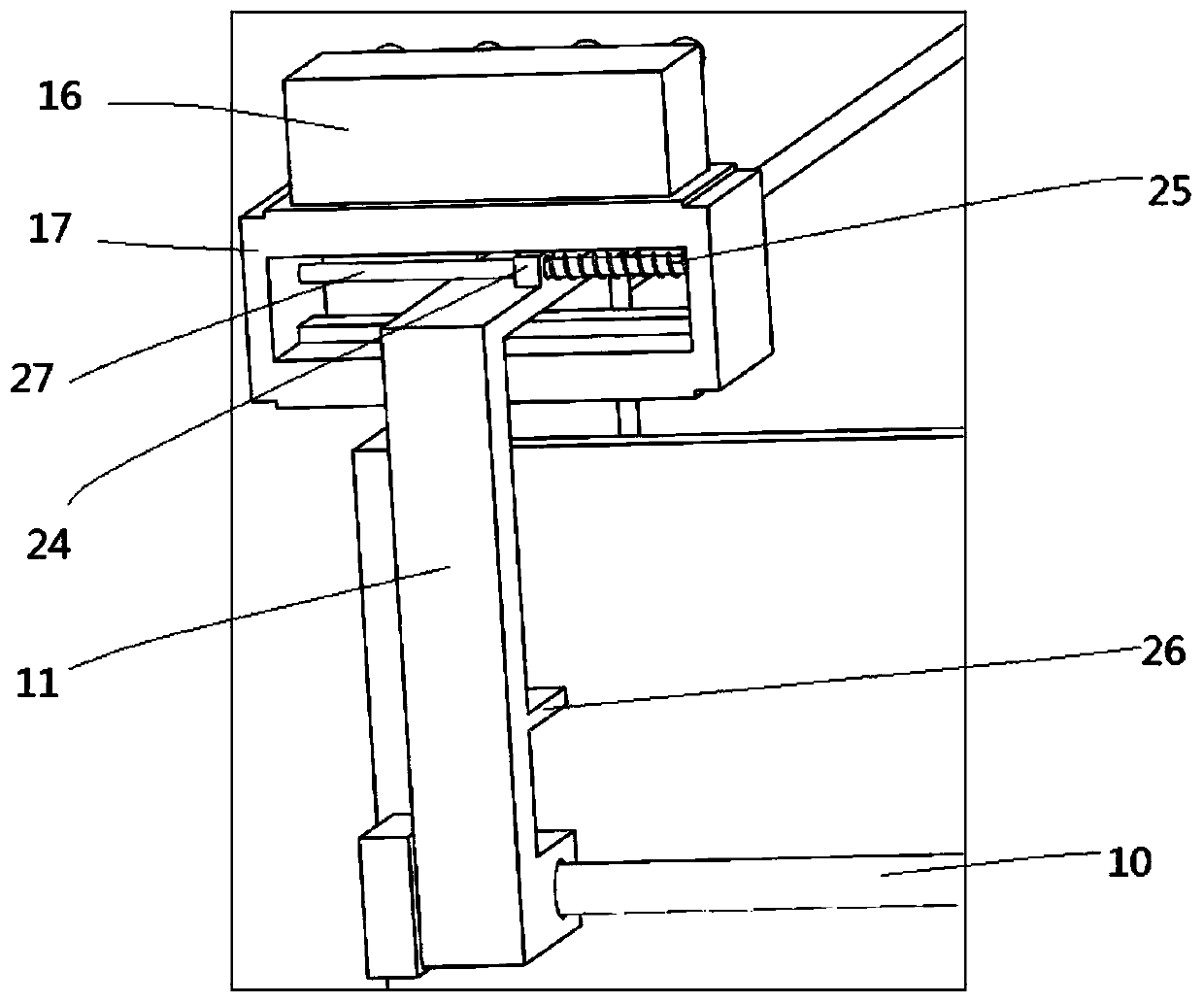

[0037] This embodiment is a further improvement on the basis of Embodiment 1. The drying mechanism includes a movable support frame 11, a second hot air blower 16, and a mounting frame 17, wherein the movable support frame 11 is an L-shaped plate, and the movable The longitudinal section of support frame 11 is positioned at collection box 2 outsides, and is slidably connected with the outer wall of collection box 2; On the mounting frame 17, a plurality of blowing heads 23 communicated with its air outlet end are installed on the outside of the second hot air blower 16.

[0038] Wherein, the mounting frame 17 is a rectangular block, and the hollow of the mounting frame 17 is provided with a rectangular hollow portion, the transverse section of the movable support frame 11 passes through the hollow portion of the mounting frame 17, and the positioning rod 27 is fixed in the hollow portion of the mounting frame 17. The transverse section top surface of support frame 11 is also p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com