A new type of urea filter with pressure relief capability

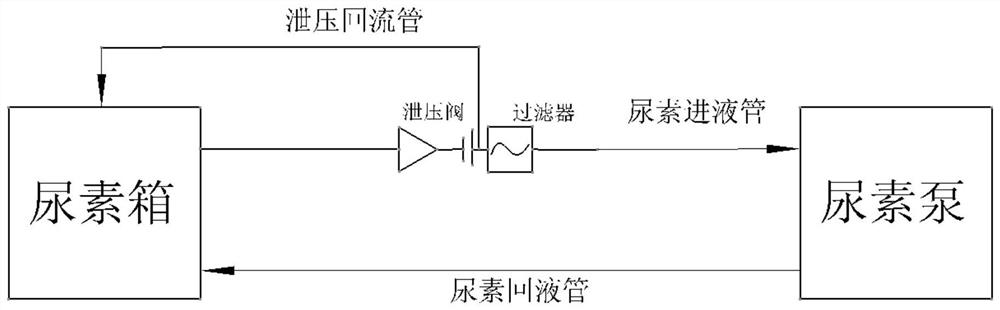

A filter and filter housing technology, used in fixed filter element filters, filtration and separation, machines/engines, etc., can solve problems such as volume expansion, limited application scope, complex structure, etc., to extend service life and ensure work. Stability, the effect of increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

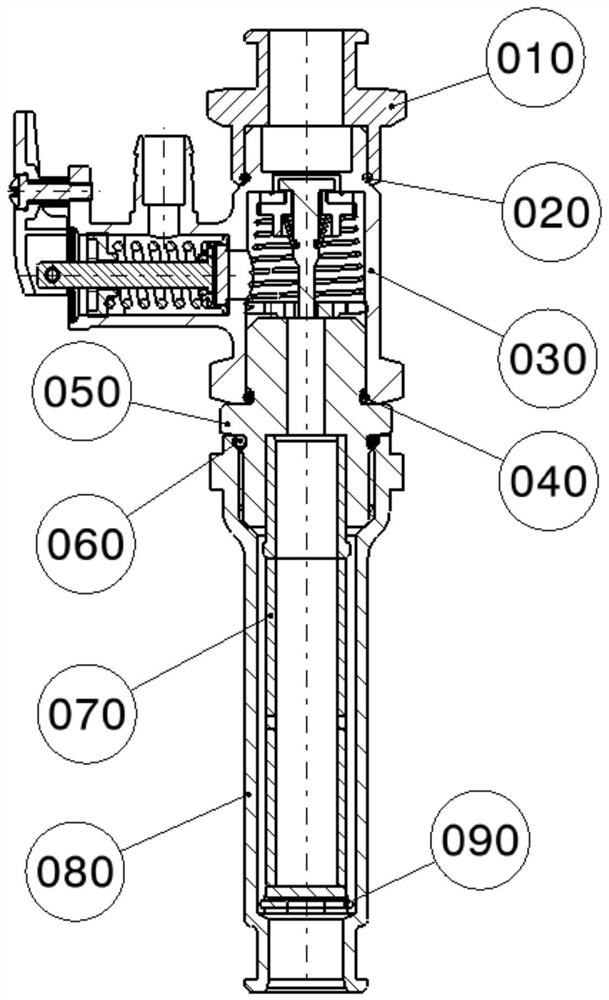

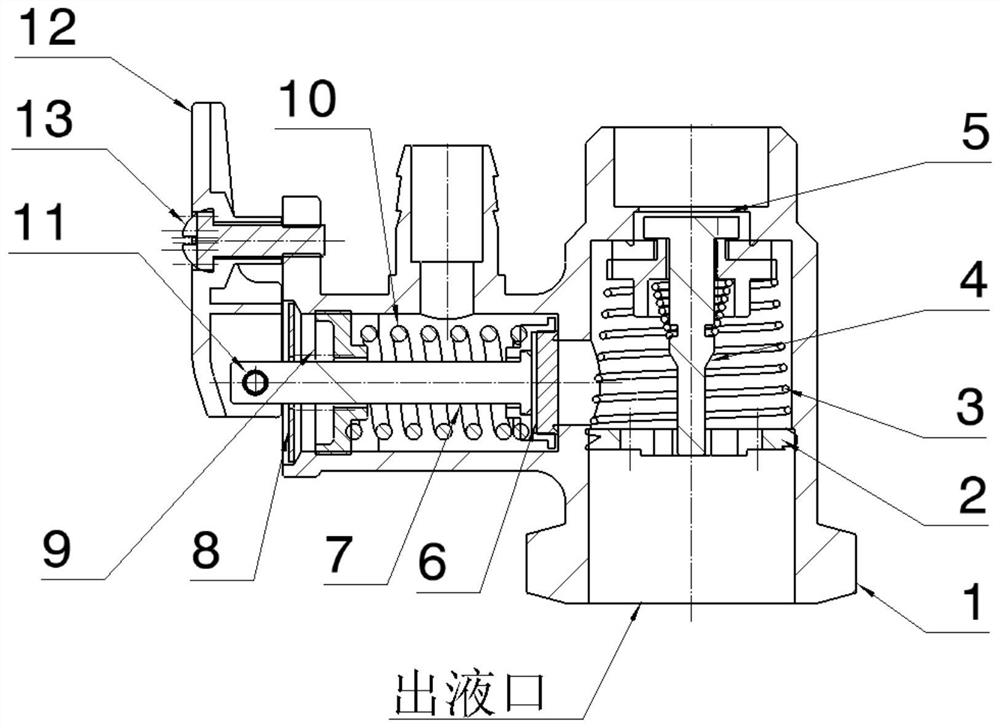

[0029] Example: a novel urea filter with pressure relief capability, such as Figure 1-Figure 9 Shown, including filter joint 010 and housing 1.

[0030] A positioning piece 2 is fixedly installed inside the upper part of the housing 1, a reverse cut-off valve spring 3 is fixedly installed on the upper end of the positioning piece 2, and a reverse valve core 4 is arranged in the middle of the reverse stop valve spring 3 A reverse cut-off valve 5 is fixedly installed on the upper end of the reverse spool 4, a safety valve 6 is arranged on the left side inside the housing 1, and a manual lever 7 is fixedly installed on the left side of the safety valve 6, so The outer circle of the manual lever 7 is sleeved with an internal sealing ring 8, the outer circle of the middle position of the manual lever 7 is sleeved with a pressure regulating disc 9, and the outer circle of the manual lever 7 is sleeved with a safety valve spring 10. A rivet 11 is provided at the left end of the man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com