Brake magnetic pole structure for linear eddy current brake device

A magnetic pole structure and braking force technology, which is applied in the field of rail vehicle braking systems, can solve the problems of increasing the slot full rate and ampere-turns, short-circuit failure, and increasing the current density of aluminum wires with the aluminum film wire winding coil technology, and achieves the goal of product The effects of increased consistency and reliability, improved packaging strength, and reduced packaging difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

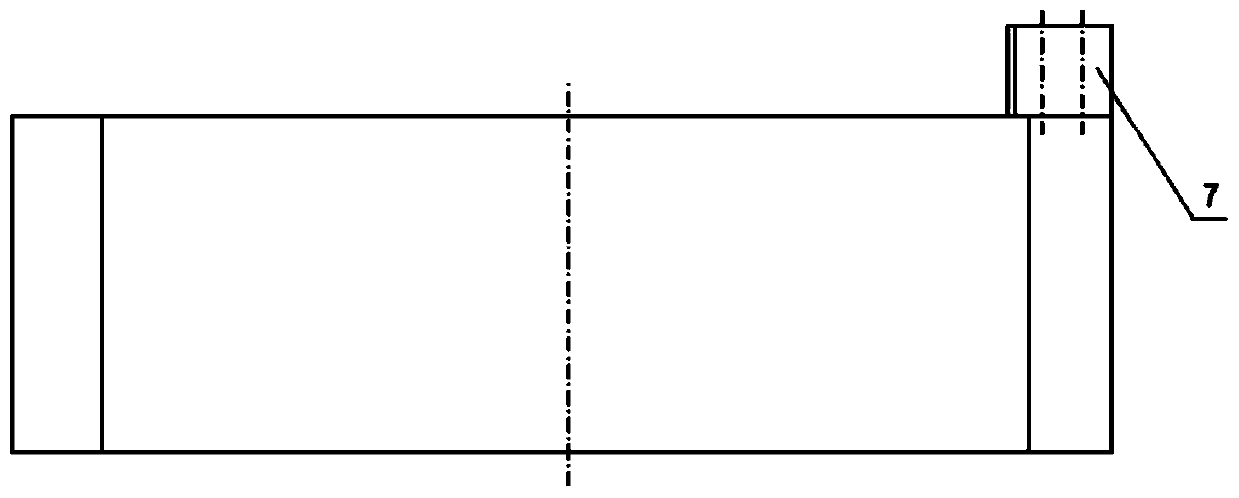

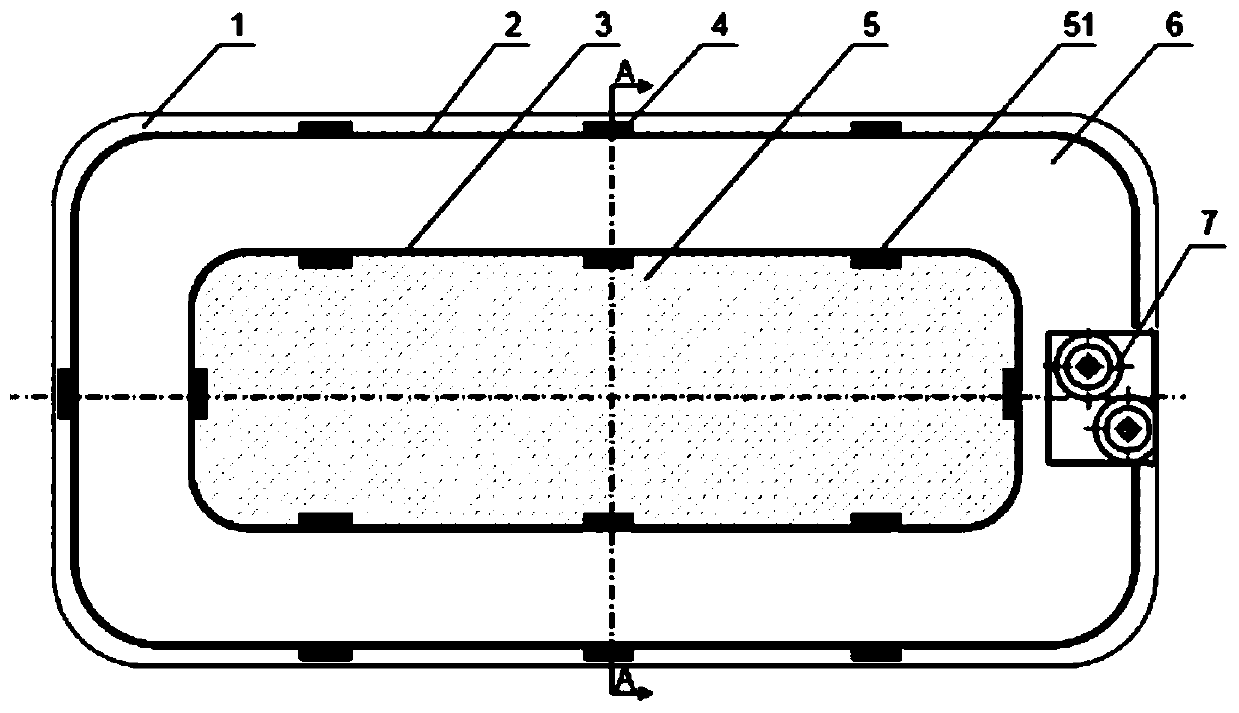

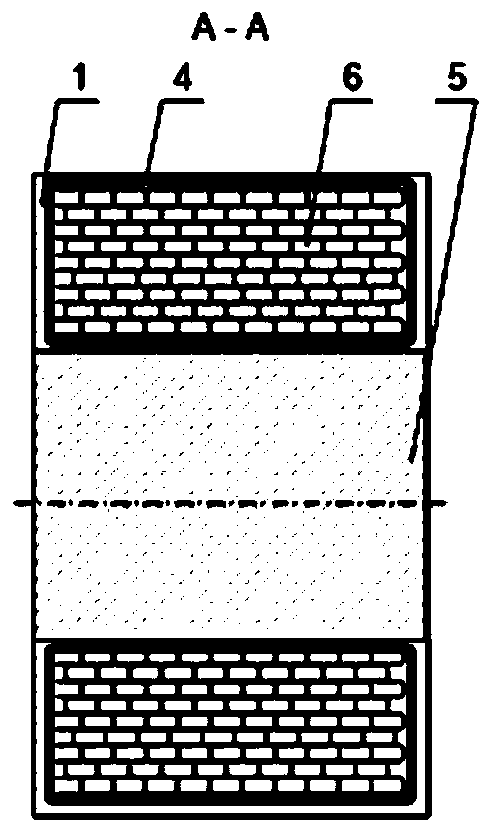

[0034] like Figure 1 to Figure 4 As shown, the magnetic pole structure of this embodiment is suitable for the braking magnetic pole structure of the linear eddy current braking device of the maglev train. The dimensions of the magnetic pole structure are: length 382.5mm, width 167mm, height 93.5mm. The brake pole mainly includes an iron core 5 , an insulating tape 3 , a coil 6 , a heat-shrinkable cable tie 4 , a glass fiber mesh 2 , an epoxy resin encapsulation layer 1 and a terminal post 7 .

[0035] Among them, the iron core 5 is made of low-carbon steel with good magnetic permeability and high strength, which is used to conduct the magnetic circuit and tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com