Special performance regulator for secondary lining concrete and preparation method thereof

A technology for concrete and conditioner, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of self-compacting concrete shrinkage, unable to restrain shrinkage cracking, etc. Frost resistance, improved appearance and interior quality, improved construction work environment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

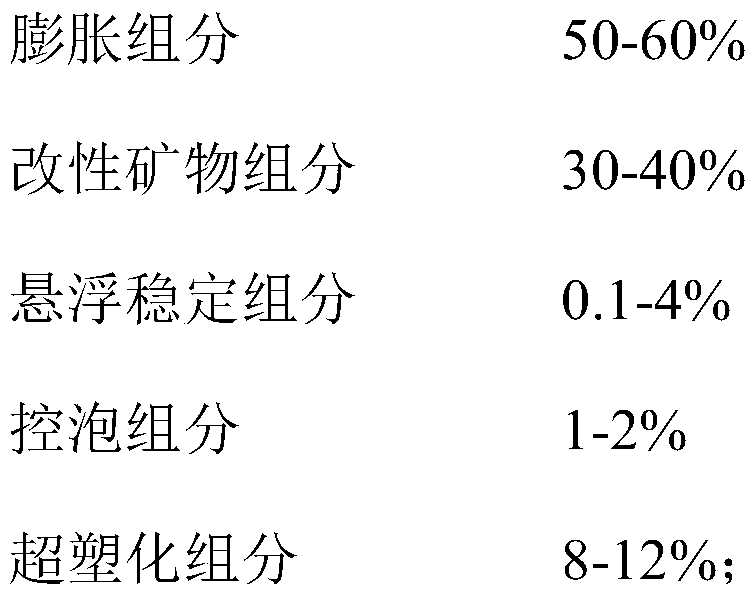

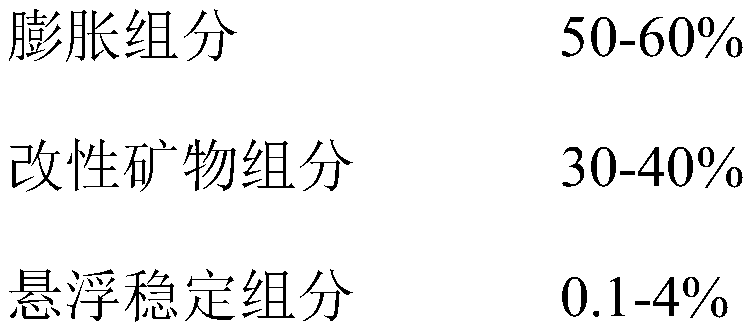

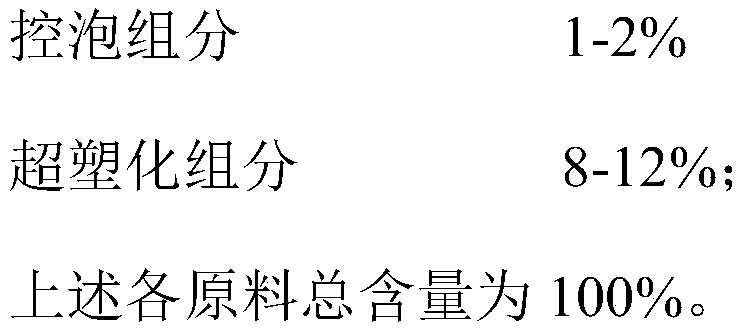

[0035] A special performance modifier for second-lined concrete, made of the following raw materials in weight percentage:

[0036] The specific surface area of 55% magnesium oxide expanded clinker and 30% jet grinding is 800kg / m 2 Fine slag powder, 2% hydroxyethyl cellulose ether, 1% foam control component, obtained by mixing silicone foam control agent and triterpene saponin air-entraining agent at a mass ratio of 1:10; 12% superplasticizing component It is obtained by mixing polycarboxylate superplasticizer powder and sodium gluconate powder at a mass ratio of 4:1.

Embodiment 2

[0038] A special performance modifier for second-lined concrete, made of the following raw materials in weight percentage:

[0039] The specific surface area of 55% magnesium oxide expanded clinker and 30% jet mill is 750kg / m 2Superfine fly ash, 2% hydroxyethyl cellulose ether, 1% foam control component, obtained by mixing silicone foam control agent and triterpene saponin air-entraining agent at a mass ratio of 1:10, 12% superplastic The chemical component is obtained by mixing polycarboxylate superplasticizer powder and sodium gluconate powder in a mass ratio of 4:1.

Embodiment 3

[0041] A special performance modifier for second-lined concrete, made of the following raw materials in weight percentage:

[0042] The specific surface area of 55% magnesium oxide expanded clinker and 10% jet grinding is 800kg / m 2 The specific surface area of fine slag powder and 20% jet milling is 750kg / m 2 Superfine fly ash, 2% hydroxyethyl cellulose ether, 1% foam control component, obtained by mixing silicone foam control agent and triterpene saponin air-entraining agent at a mass ratio of 1:10, 12% superplastic The chemical component is prepared by mixing polycarboxylate superplasticizer powder and sodium gluconate powder in a mass ratio of 4:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com