Manufacturing method of wafer-level glass cavity

A manufacturing method and wafer-level technology, applied in the manufacture of microstructure devices, techniques for producing decorative surface effects, decorative arts, etc., can solve the problem that it is difficult to obtain cavities with a depth greater than 50um, and the back of a glass sheet cannot be obtained very well. Good protection, depth cannot be precisely controlled, etc., to achieve the effect of eliminating surface undercutting, reducing defects and pinholes, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

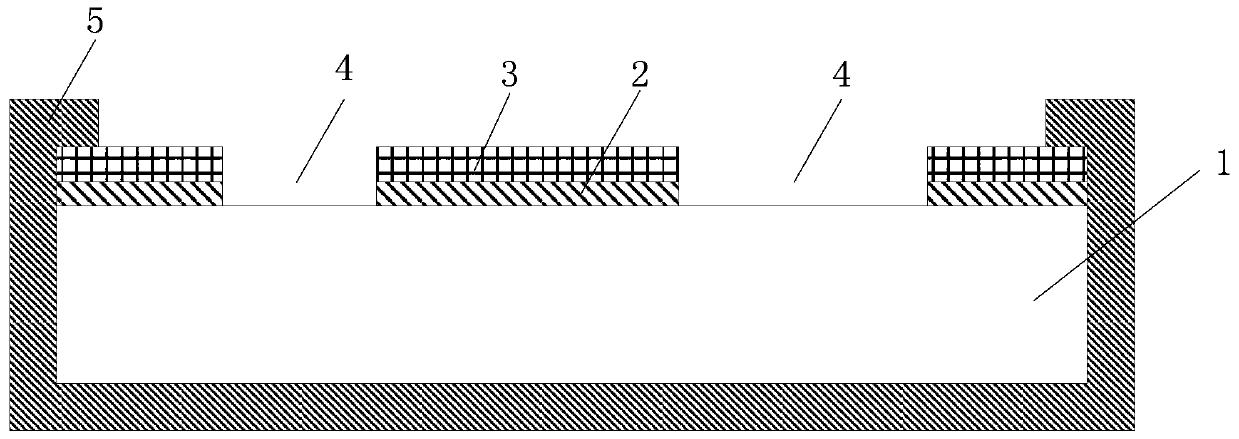

Embodiment 1

[0043] In the first step, the Pyrex7740 glass slides were successively soaked with 120°C 3# solution (H 2 SO 4 :H 2 o 2 =4:1) Wash for 20min, 1# solution (NH 4 OH:H 2 o 2 :H 2 O=1:1:5) wash for 20min, 2# solution (HCl: H 2 o 2 :H 2 O=1:1:6) Wash for 20 minutes, rinse with water, and shake dry.

[0044] In the second step, put the glass sheet in 60°C, 20% KOH solution for cleaning for 10 minutes, rinse with water, and spin dry.

[0045] In the third step, a Cr / Au film with a thickness of 40nm / 200nm is deposited on one side of the glass sheet by using a magnetron sputtering station.

[0046] The fourth step is to apply i7010 photoresist on the metal surface of the glass sheet with a thickness of 2 μm, and use photolithography and dry etching to form a specific pattern on the Cr / Au film and expose the glass surface.

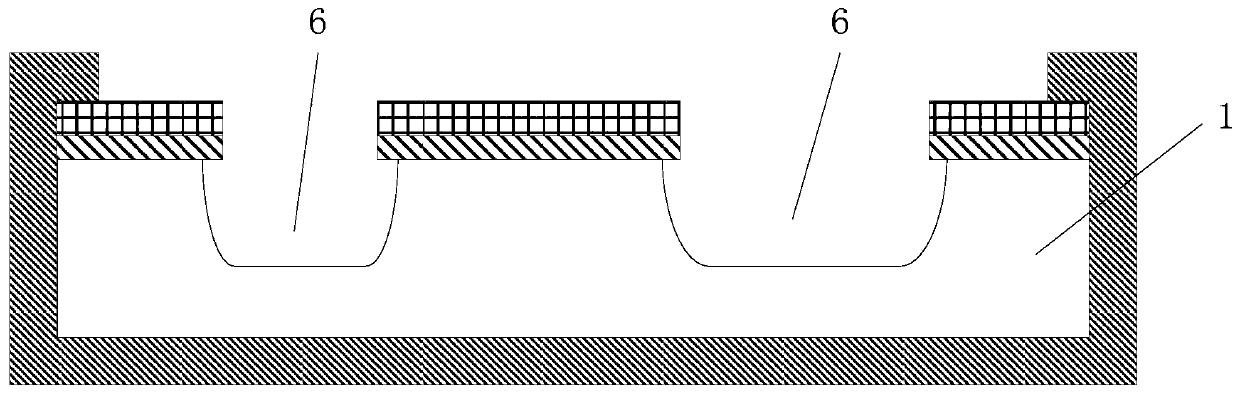

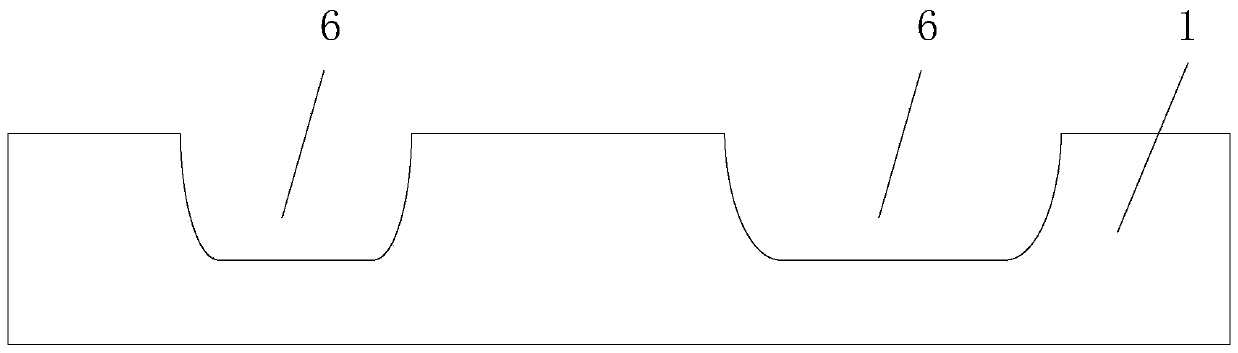

[0047] The fifth step is to use SPV225 blue film (thickness 80μm). Airtightly bond the edge of the glass sheet and the surface without the gold film.

...

Embodiment 2

[0051]In the first step, the TEMPAX glass sheets were successively soaked with 120°C 3# liquid (H 2 SO 4 :H 2 o 2 =4:1) Wash for 20min, 1# solution (NH 4 OH:H 2 o 2 :H 2 O=1:1:5) wash for 20min, 2# solution (HCl: H 2 o 2 :H 2 O=1:1:6) Wash for 20 minutes, rinse with water, and shake dry.

[0052] In the second step, put the glass sheet in 80°C, 40% KOH solution for cleaning for 20 minutes, rinse with water, and spin dry.

[0053] In the third step, a Ti / Au film with a thickness of 40nm / 400nm is deposited on one side of the glass sheet by using a magnetron sputtering station.

[0054] The fourth step is to apply 108cp photoresist on the metal surface of the glass sheet with a thickness of 5 μm, and use photolithography and dry etching to form a specific pattern on the Ti / Au film and expose the glass surface.

[0055] The fifth step is to use SPV224 blue film (thickness 80μm, adhesion force 1.10N / mm 2 ) Airtightly bond the edge of the glass sheet and the surface with...

Embodiment 3

[0059] In the first step, the TEMPAX glass sheets were successively soaked with 120°C 3# liquid (H 2 SO 4 :H 2 o 2 =4:1) Wash for 20min, 1# solution (NH 4 OH:H 2 o 2 :H 2 O=1:1:5) wash for 20min, 2# solution (HCl: H 2 o 2 :H 2 O=1:1:6) Wash for 20 minutes, rinse with water, and shake dry.

[0060] In the second step, put the glass sheet in 80°C, 40% KOH solution for cleaning for 20 minutes, rinse with water, and spin dry.

[0061] In the third step, a Ti / Au film with a thickness of 40nm / 800nm is deposited on one side of the glass sheet by using a magnetron sputtering station.

[0062] The fourth step is to apply AZ4620 photoresist on the metal surface of the glass sheet with a thickness of 10 μm, and use photolithography and wet etching to form a specific pattern on the Ti / Au film and expose the glass surface.

[0063] The fifth step is to use SPV224 blue film (thickness 80μm, adhesion force 1.10N / mm 2 ) Airtightly bond the edge of the glass sheet and the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com