Double-row multi-head copper foil winding device

A copper foil and tape winding technology is applied in the field of double-row multi-head copper foil tape winding devices, which can solve the problems of complex overall structure of copper foil tape winding machines, difficult manufacturing, processing and maintenance, occupation of copper foil tape winding machines, etc. Ensure the flexibility and practicality of use, reduce the overall occupied space, and simplify the effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

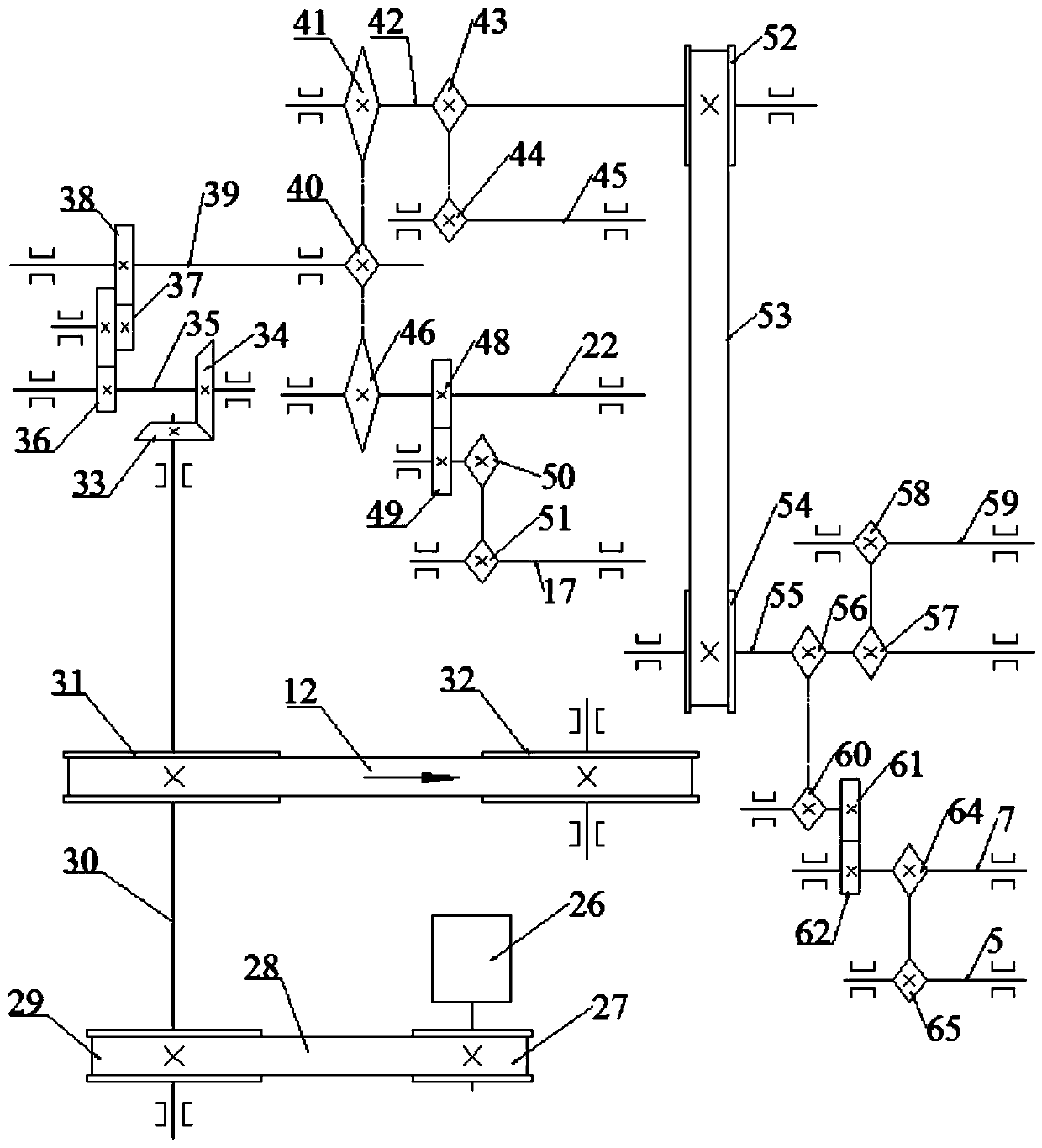

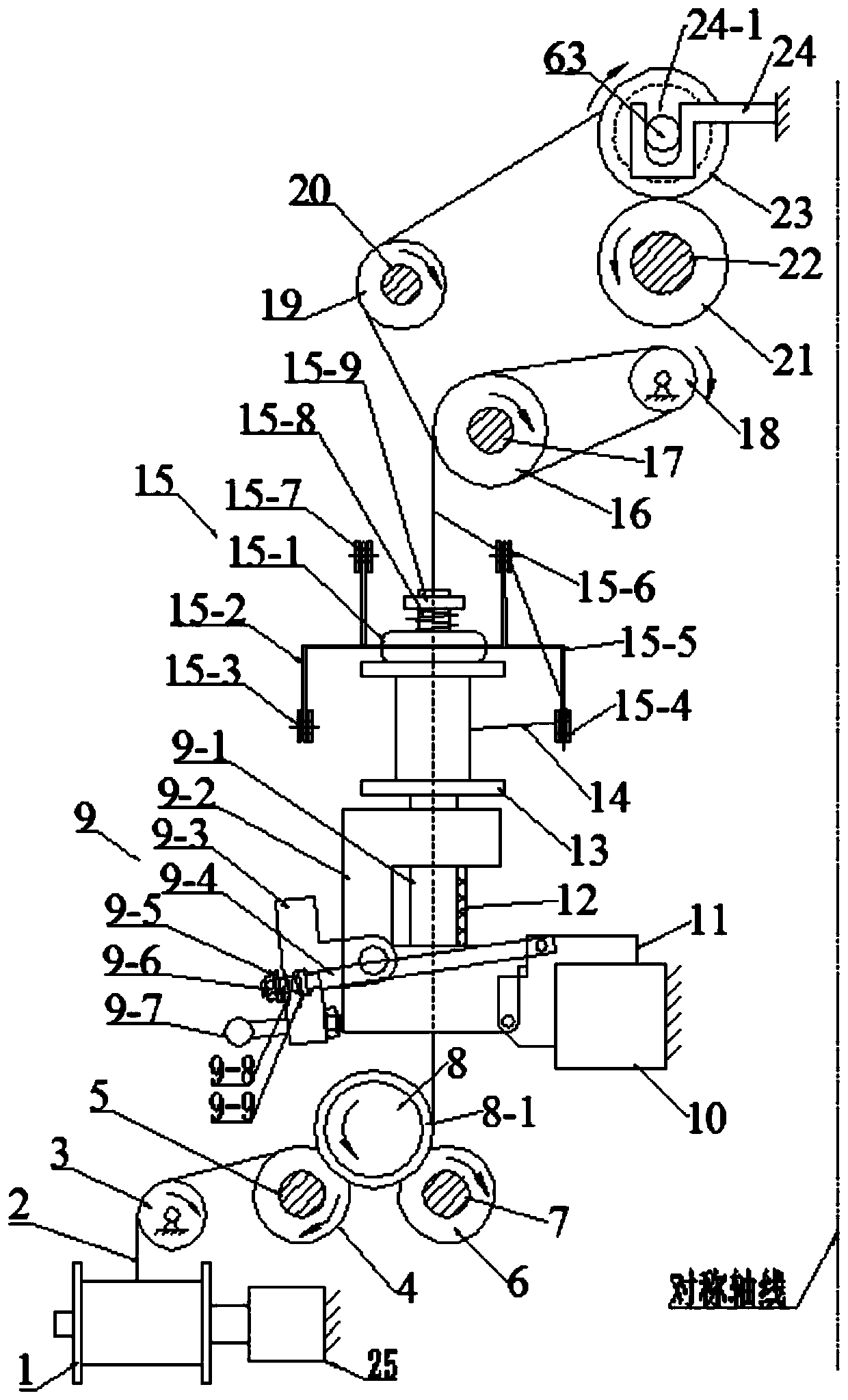

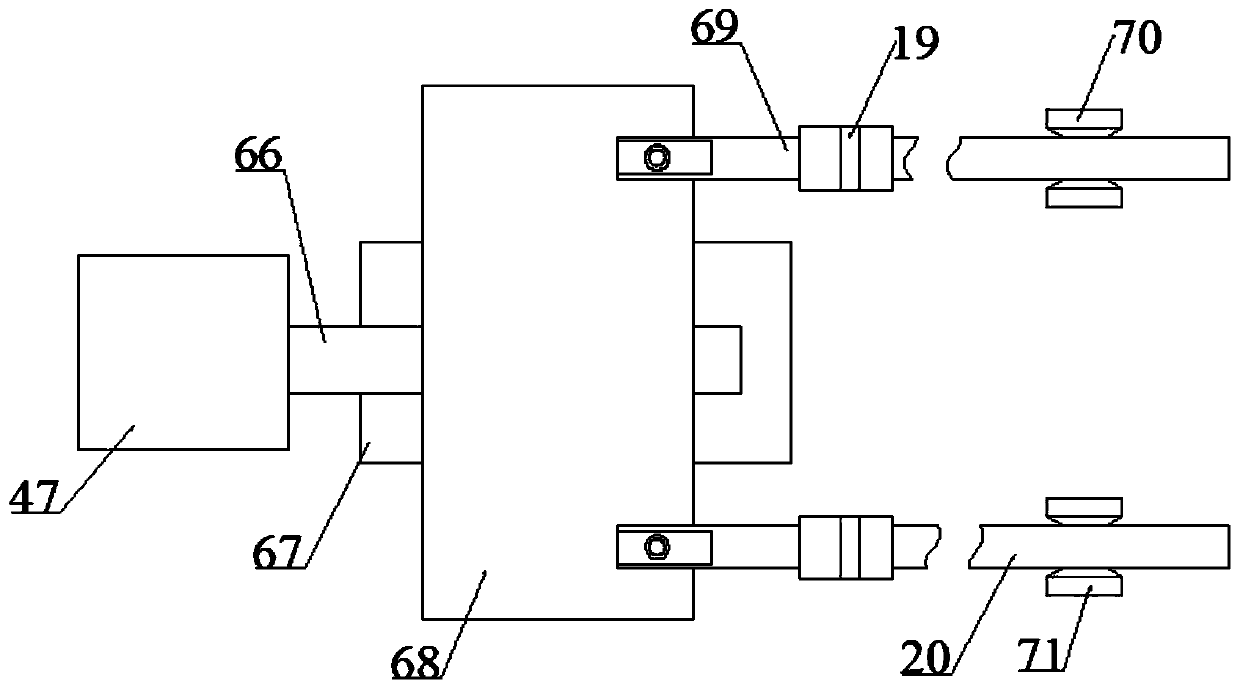

[0031] Such as Figure 1~3 As shown, the present invention is a double-row multi-head copper foil tape winding device, including a transmission mechanism, two horizontal beams 10 arranged in parallel, a driving motor 26 and a frame in the middle of the two horizontal beams 10, wherein One horizontal beam body 10 is fixed on the front side of the frame, and the other horizontal beam body 10 is correspondingly fixed on the rear side of the frame. Two horizontal beam bodies 10 are respectively fixed with a number of copper foil winding machines at intervals. The copper foil winding machines all include a pay-off unit, a tape unit, a traction unit and a take-up unit connected in sequence, and the pay-off unit, the traction unit and the take-up unit are all installed on the frame, and the drive The output shaft of the motor 26 is connected to the transmission mechanism, and the drive motor 26 provides driving force for several copper foil winding machines respectively through the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com