Composite waterproof wax as well as preparation method and application thereof

A technology of paraffin wax and fully refined paraffin wax, which is applied in applications, other household appliances, household components, etc., and can solve problems such as discounting of waterproof effect, desorption of paraffin wax and fiber, and improvement of waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides the preparation method of the composite waterproof wax described in the above technical scheme, comprising the following steps:

[0031] The paraffin wax, crystallization modifier, surface active agent, penetrating agent and propping agent are mixed to obtain the composite waterproof wax.

[0032] The invention mixes paraffin wax, crystal modifier, surface active agent, penetrating agent and propping agent to obtain the composite waterproof wax. In the present invention, the mixing preferably includes the following steps:

[0033] Heating paraffin to melt; obtaining liquid paraffin;

[0034] performing the first mixing of the liquid paraffin, the crystallization modifier and the proppant to obtain a first mixture;

[0035] performing a second mixing of the first mixture, penetrant and surfactant to obtain a second mixture;

[0036] The second mixture is cooled and discharged to obtain the composite waterproof wax.

[0037] In the prese...

Embodiment 1

[0050] No. 75g No. 54 semi-refined paraffin wax is heated to 80 ℃, after melting completely, obtains liquid paraffin; The first mixing of described liquid paraffin, 10g polyamide wax and 8g hydrogenated styrene-butadiene block copolymer (temperature is 85 ℃, the stirring speed is 300rpm, and the stirring time is 80min), to obtain the first mixture; the first mixture, 15g No. 26 white oil and 10g octadecylamine are mixed for the second time (the temperature is 90°C, and the stirring speed is 100rpm, the stirring time is 30min) to obtain the second mixture; the second mixture is cooled to 60°C and discharged to obtain the composite waterproof wax.

Embodiment 2

[0052] No. 59g No. 56 semi-refined paraffin wax is heated to 90 DEG C, and after melting completely, liquid paraffin is obtained; The liquid paraffin, 5g polyamide wax and 3g hydrogenated styrene-butadiene block copolymer are mixed for the first time (temperature is 90 ℃, the stirring speed is 150rpm, and the stirring time is 80min), to obtain the first mixture; the first mixture, 5g vegetable methyl oleate and 5g octadecyl phosphate are mixed for the second time (the temperature is 100°C, The stirring speed is 100 rpm, and the stirring time is 30 min) to obtain the second mixture; the second mixture is cooled to 60° C. and discharged to obtain the composite waterproof wax.

PUM

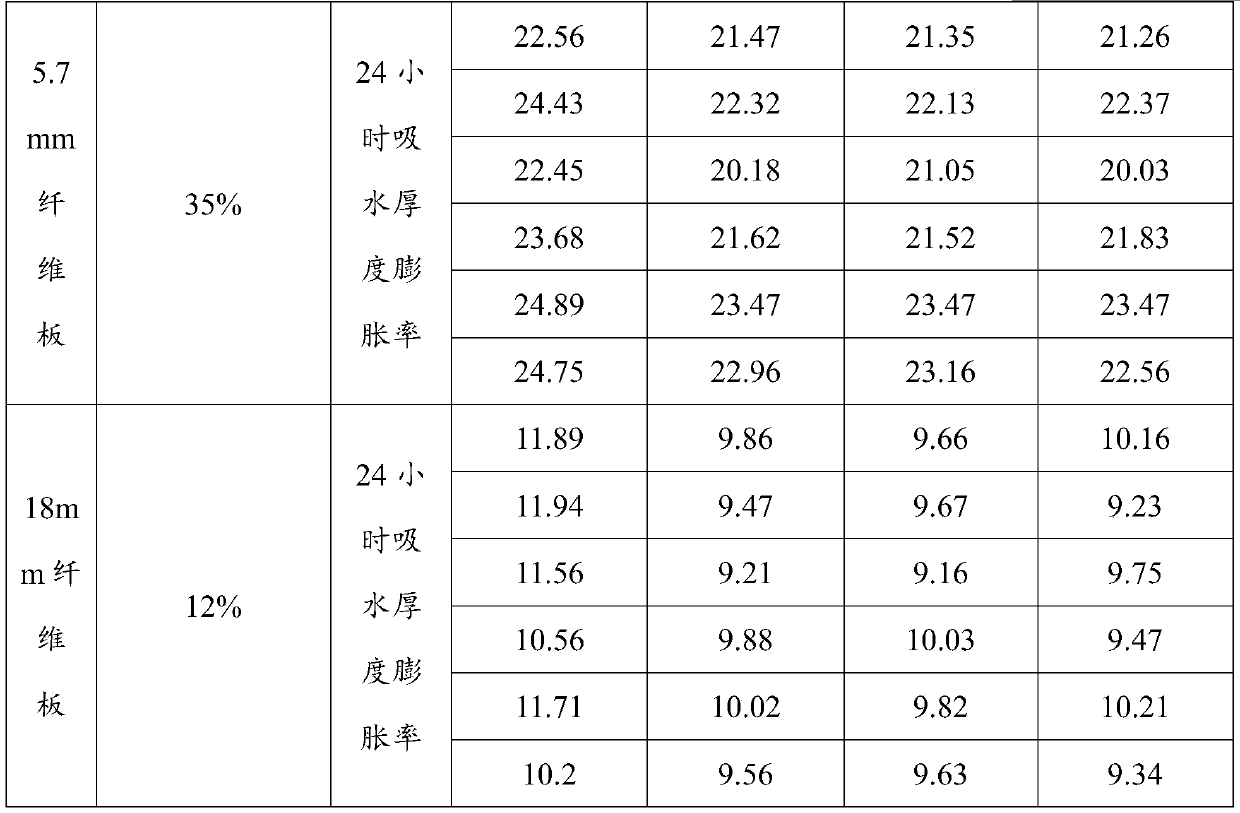

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com