A two-way pressurized feed puffing processing device for agricultural breeding

A processing device and feed technology, which is applied in the direction of extrusion and granulation of feed and raw materials, and application, can solve the problems of incomplete feed expansion, inability to ensure sufficient pressure and balance, affecting processing efficiency, etc. The effect of high degree and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

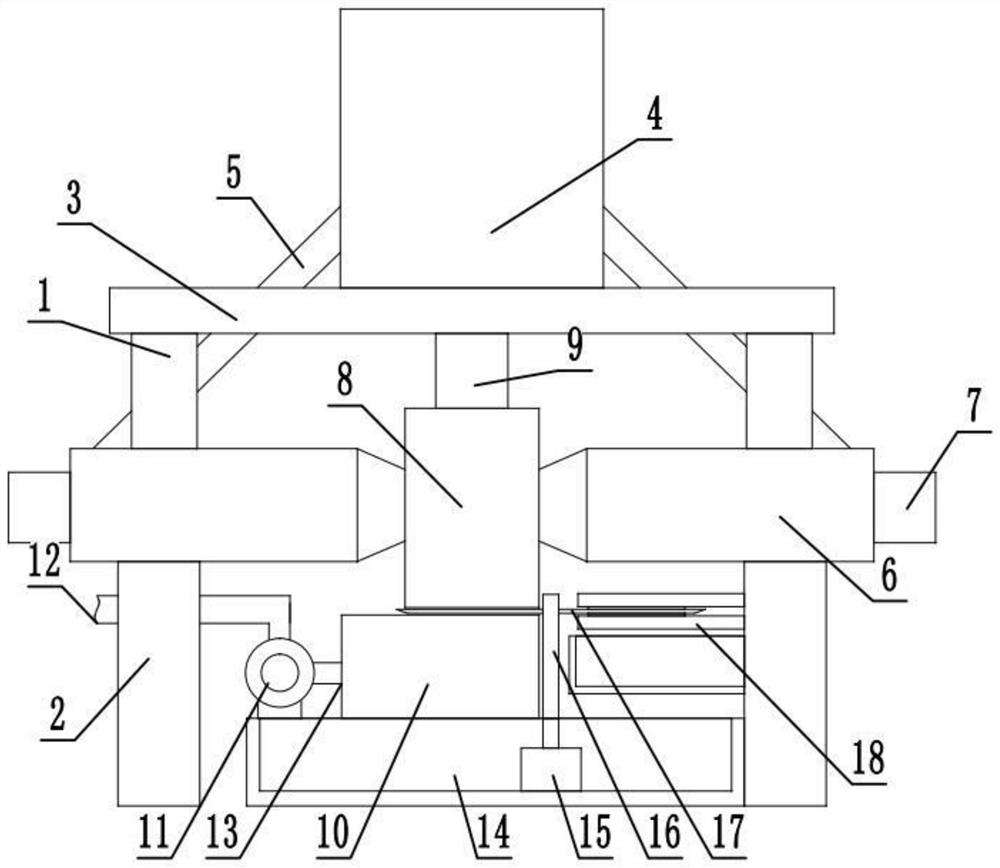

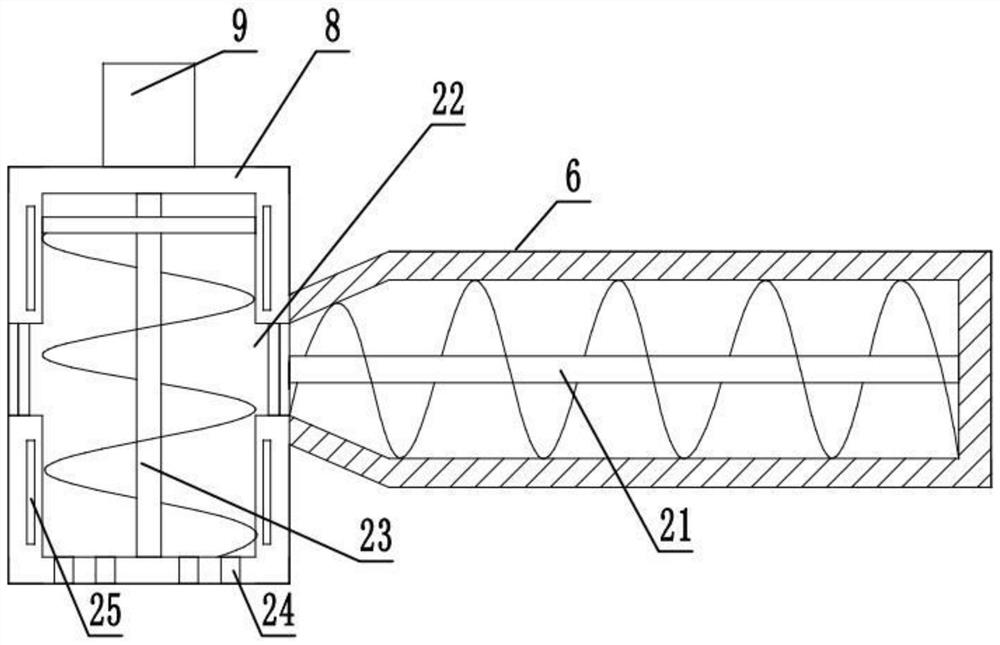

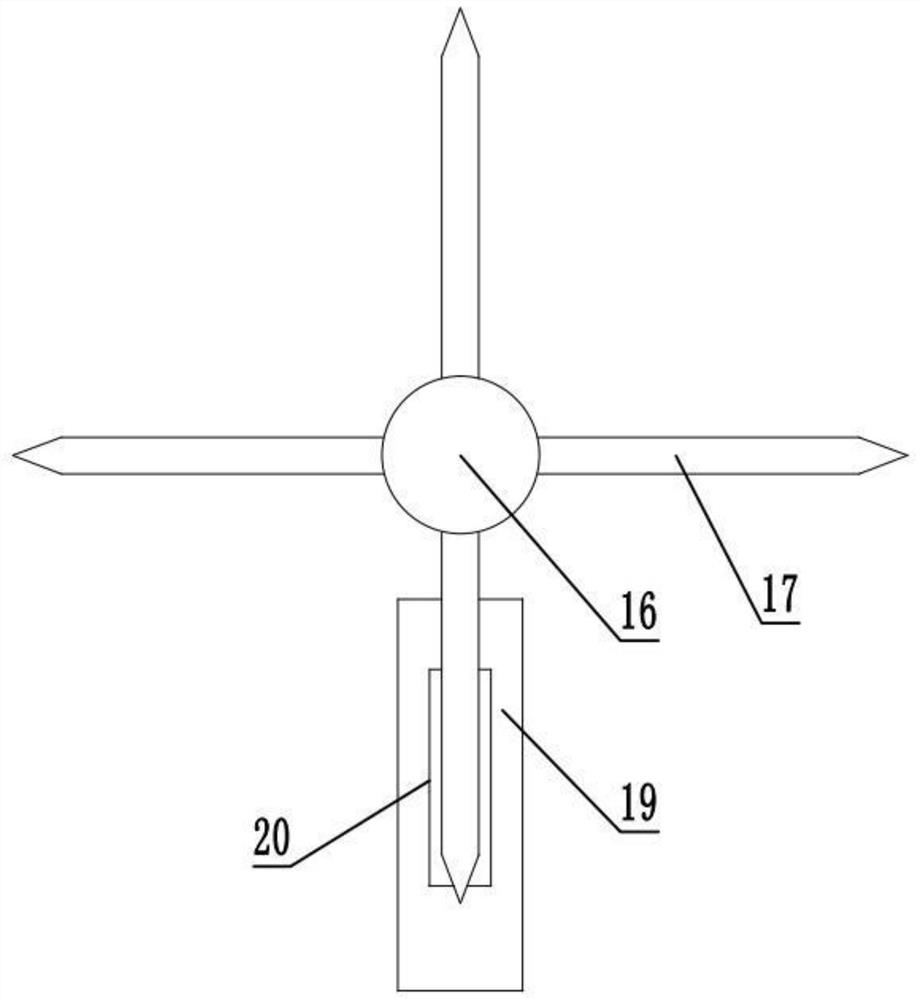

[0020] see Figure 1-4 , a two-way pressurized feed puffing processing device for agricultural breeding, comprising a frame 1, the frame 1 has a plurality of support legs 2 and a support platform 3, a raw material box 4 is arranged above the frame 1, and a raw material box 4 is arranged below the frame 1 An extrusion cylinder 8 is provided, and a pressurized delivery cylinder 6 communicating with it is provided at the central position on both sides of the extrusion cylinder 8. The pressurized delivery cylinder 6 is embedded on the support leg 2 and is fixedly connected with the support leg 2. The lower part of both sides of the raw material box 4 is provided with a delivery pipe 5 communicating with the raw material box 4 and the pressurized delivery cylinder 6, and the side of the extrusion cylinder 8 is provided with a delivery port 22 for communicating with the pressurized delivery cylinder 6. 8, a plurality of heating rods 25 are embedded in the inner wall, and a finished ...

Embodiment 2

[0024] refer to Figure 5 , on the basis of Embodiment 1, the lower part of the raw material box 4 is provided with a guide slide 28, the top surface of the guide slide 28 is inclined downward from the middle to both sides, and the outside of the guide slide 28 is connected to the delivery pipe 5 Docking, a guider 30 is provided at the connection between the raw material box 4 and the delivery pipe 5, the guider 30 has a rotating shaft and a plurality of material guide plates positioned on the rotating shaft, and the rotating shaft is driven by a motor located outside the delivery pipe 5 Rotate, when carrying out the transfer of raw material to pressurized conveying cylinder 6, rotate by guider 30, avoid the situation that raw material is piled up and blocked and can't transfer.

[0025] Further, the guide slide 28 is provided with an auxiliary heater 29, the auxiliary heater 29 can adopt a plurality of PTC ceramic heating tubes, and the raw material is preheated through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com