Circuit structure for improving peeling strength of pins in COF-IC packaging process

A COF-IC, peel strength technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of small adhesion strength of flexible substrates, circuit break or short circuit, copper wire stripping substrates, etc., to improve product quality efficiency, increase product life, and enhance the effect of adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

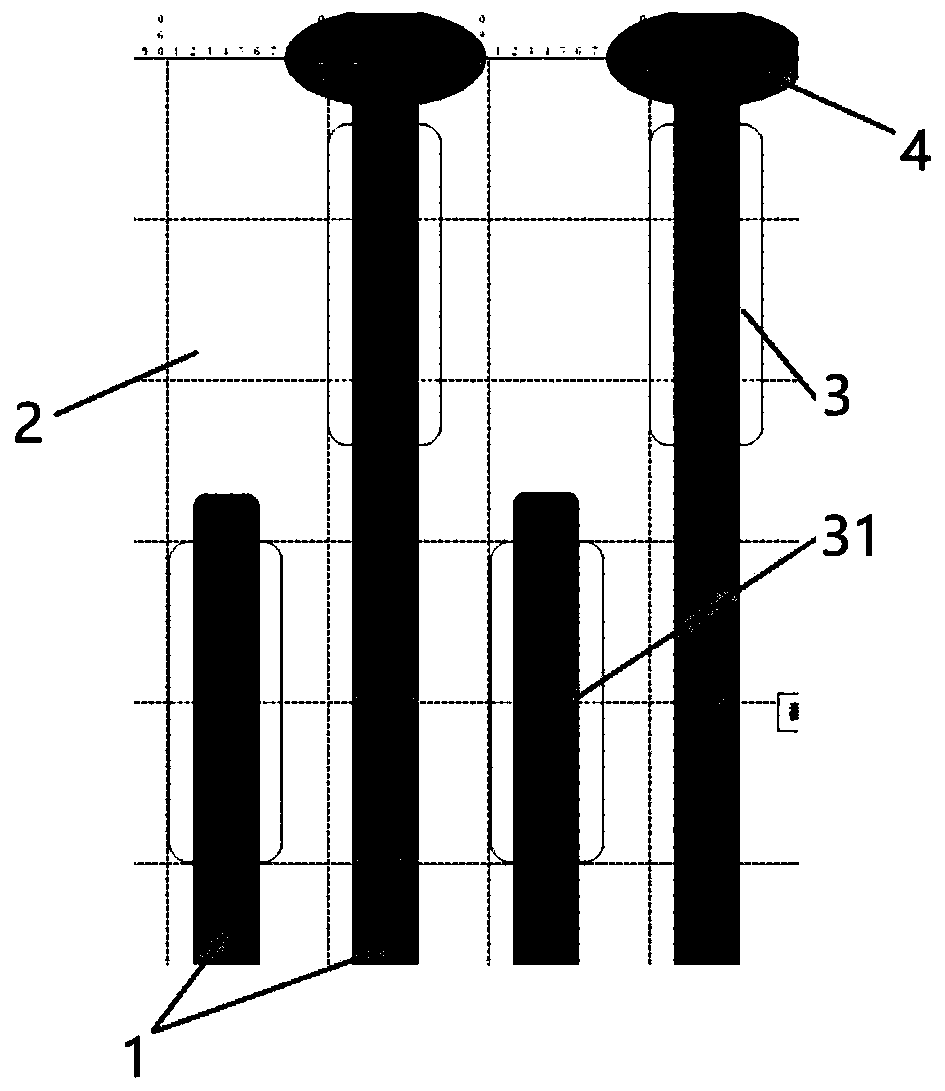

[0033] Such as figure 1 As shown, the copper wire 1 is attached to the flexible substrate 2, and the pins of the IC chip are fixedly connected to the pins of the copper wire 1 by pressure welding. The pins of the copper wire 1 are located at the end of the copper wire 1, and the copper wire 1 The pins include long pins 3 and short pins 31, the long pins 3 and short pins 31 are arranged at intervals, the long pins 3 have the same structure as the copper wire 1, and are long strips; the short pins 31 and the copper wire 1 The structures are the same, and are in the shape of a strip; the upper end of the long pin 3 is fixed with a wire reel 4, and the wire reel 4 is elliptical.

Embodiment 2

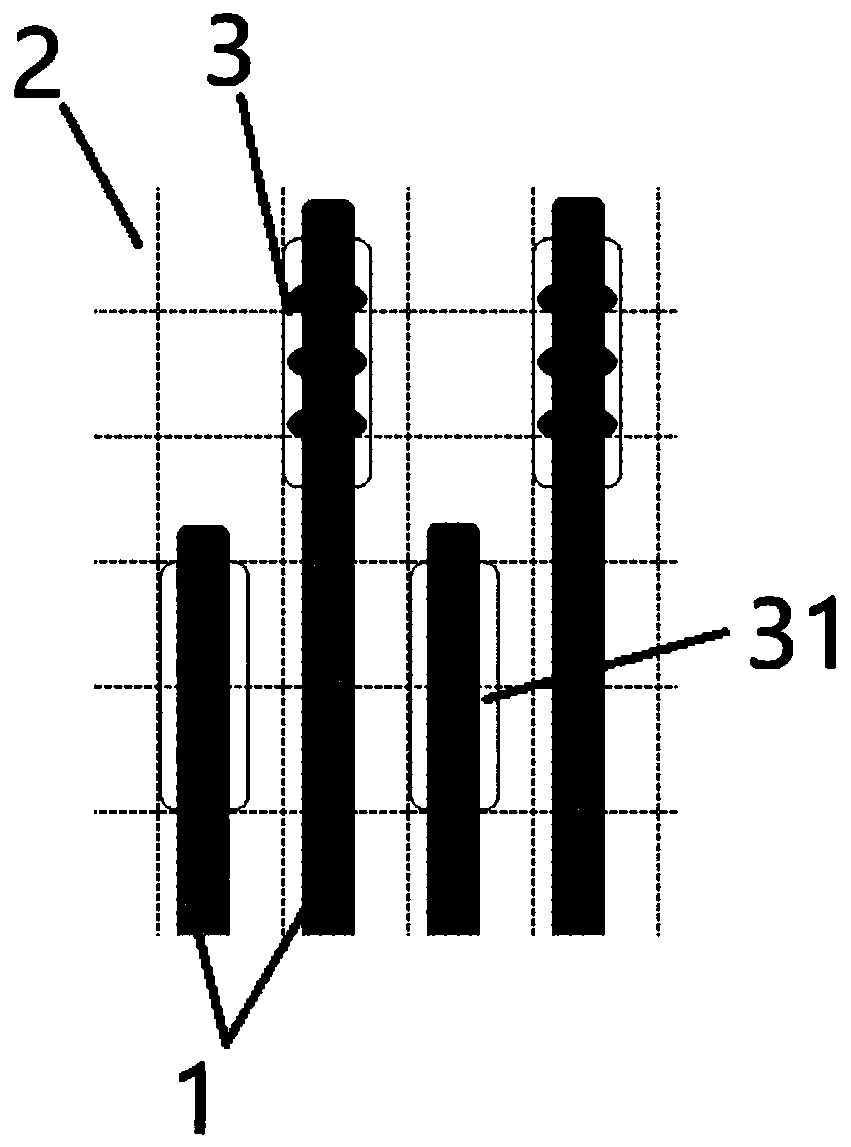

[0035] Such as figure 2 As shown, the copper wire 1 is attached to the flexible substrate 2, and the pins of the IC chip are fixedly connected to the pins of the copper wire 1 by pressure welding. The pins of the copper wire 1 are located at the end of the copper wire 1, and the copper wire 1 The pins include long pins 3 and short pins 31, and the long pins 3 and short pins 31 are arranged at intervals; the short pins 31 have the same structure as the copper wire 1, and are long strips; the long pins 3 are two-sided The extended "Feng"-shaped structure has an oval-shaped extension.

Embodiment 3

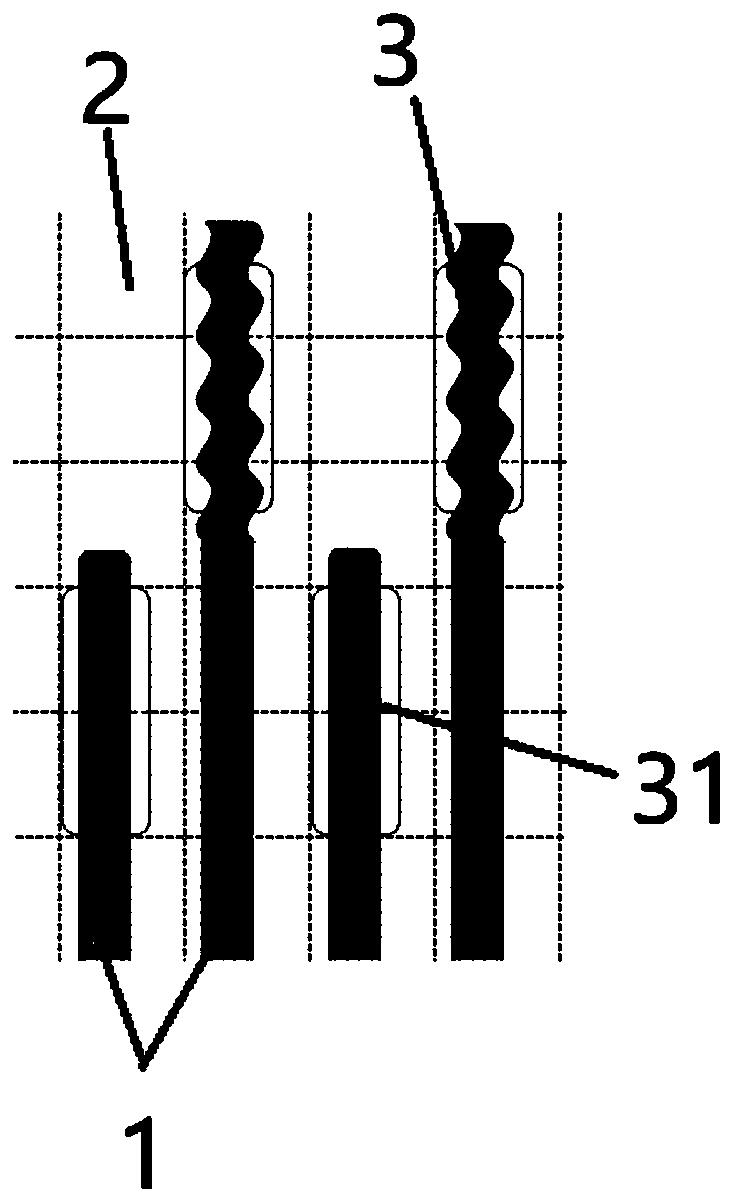

[0037] Such as image 3 As shown, the main structure of embodiment 3 is the same as that of embodiment 2, the difference is that the long pin 3 is a wave-shaped structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com