Method for backfilling reclamation mining pits by weathering type bauxite beneficiation and slurry and red mud generated by smelting

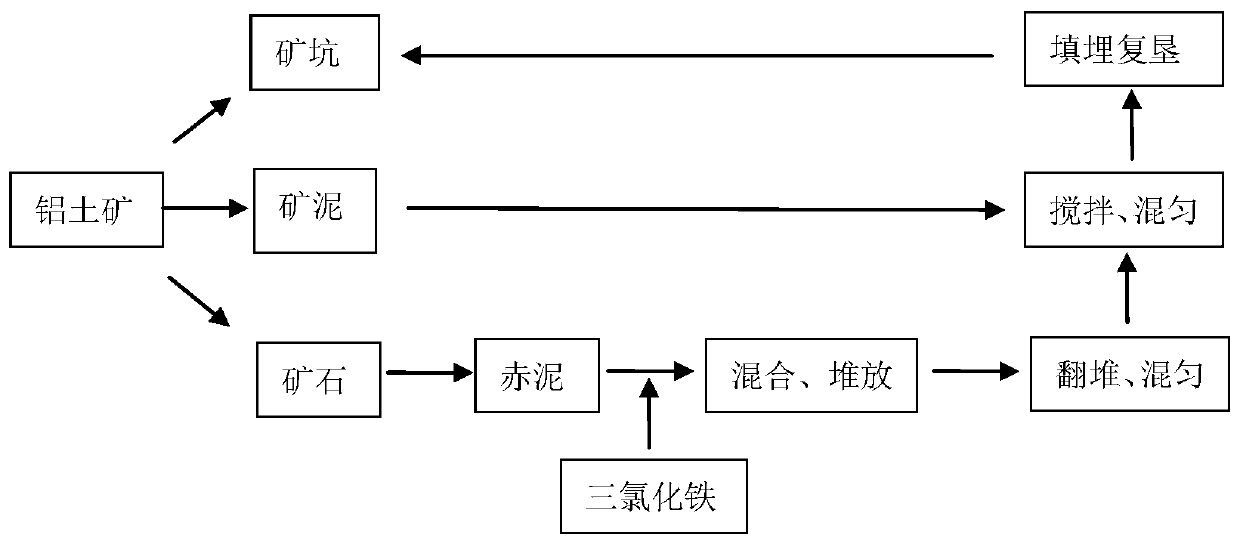

A technology of bauxite and red mud, which is applied in the field of backfilling and reclamation of mining pits with red mud, and the slime produced by smelting, and in the field of beneficiation of bauxite, which can solve the problems of lack of effective disposal measures for red mud and slime. Achieve good ecological benefits, protect the ecological environment, and control the cost of process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Land reclamation of pit slime and red mud in a bauxite mining area in Pingguo County, Guangxi

[0025] (1) The raw materials are weighed according to the following weight percentage (dry weight): the proportion of ingredients is: 80% of ore slime, 19% of red mud, 0.7% of anhydrous ferric chloride, and 0.3% of gypsum; the pit volume is 5000m 3 , the total material weight (dry weight) is about 9,000 tons; material quality: 13,100 tons of ore slime with a moisture content of 45%, 2,445 tons of red mud with a moisture content of 30%, and 57 tons of anhydrous ferric chloride (powder, purity 98%) , 24.5 tons of 180 mesh gypsum powder (moisture content 2%).

[0026] (2) Use a forklift to level a piece of 30ⅹ30m in the red mud yard 2 The site is used as a place for mixing, stacking and aging red mud to reduce alkali. The specific alkali reduction and mixing steps are as follows: ①Take the load capacity of the transport vehicle in the red mud yard as the basic unit ...

Embodiment 2

[0028] Example 2: Land reclamation of pit slime and red mud in a bauxite mining area in Baise City, Guangxi

[0029] (1) The raw materials are weighed according to the following weight percentage (dry weight): the proportion of ingredients is: 85% of ore slime, 14.1% of red mud, 0.6% of anhydrous ferric chloride, and 0.3% of gypsum; the pit volume is 10000m 3 , the total weight of the material (dry weight) is about 18,000 tons; the quality of the material: 28,333 tons of ore slime with a moisture content of 44%, 3,626 tons of red mud with a moisture content of 30%, and 108 tons of anhydrous ferric chloride (powder, purity 96%) , 54 tons of 180 mesh gypsum powder (moisture content 2%).

[0030] (2) Use a forklift to level a piece of 40ⅹ40m in the red mud yard 2 The site is used as a place for mixing, stacking and aging red mud to reduce alkali. The specific alkali reduction and mixing steps are as follows: ①Take the load capacity of the transport vehicle in the red mud yard a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com