Novel prefabricated component wall-column connection structure and installation method thereof

A technology of prefabricated components and connecting structures, applied in the direction of structural elements, building components, building types, etc., can solve problems such as differences, achieve the effects of reducing engineering volume, speeding up construction speed, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

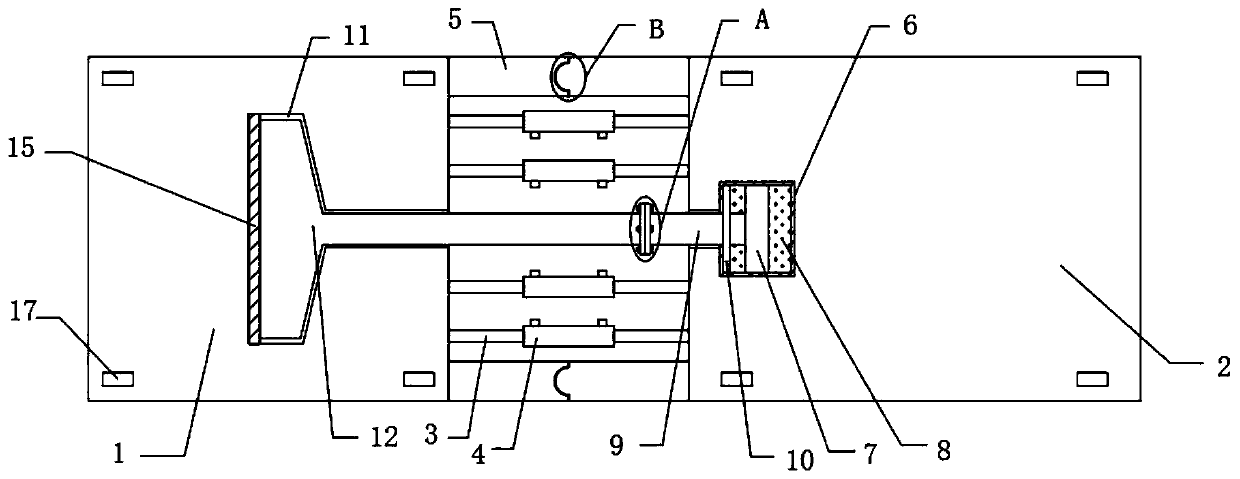

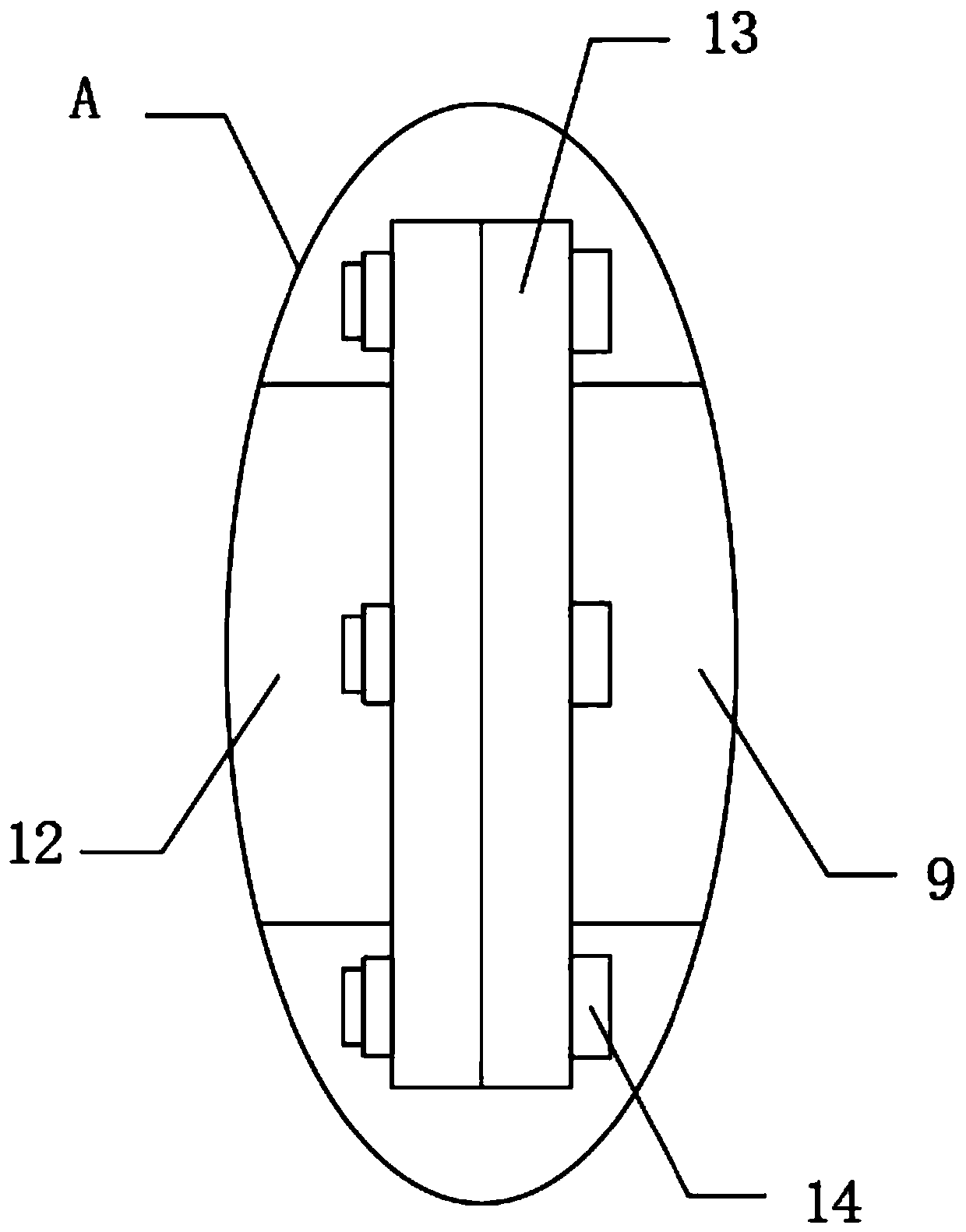

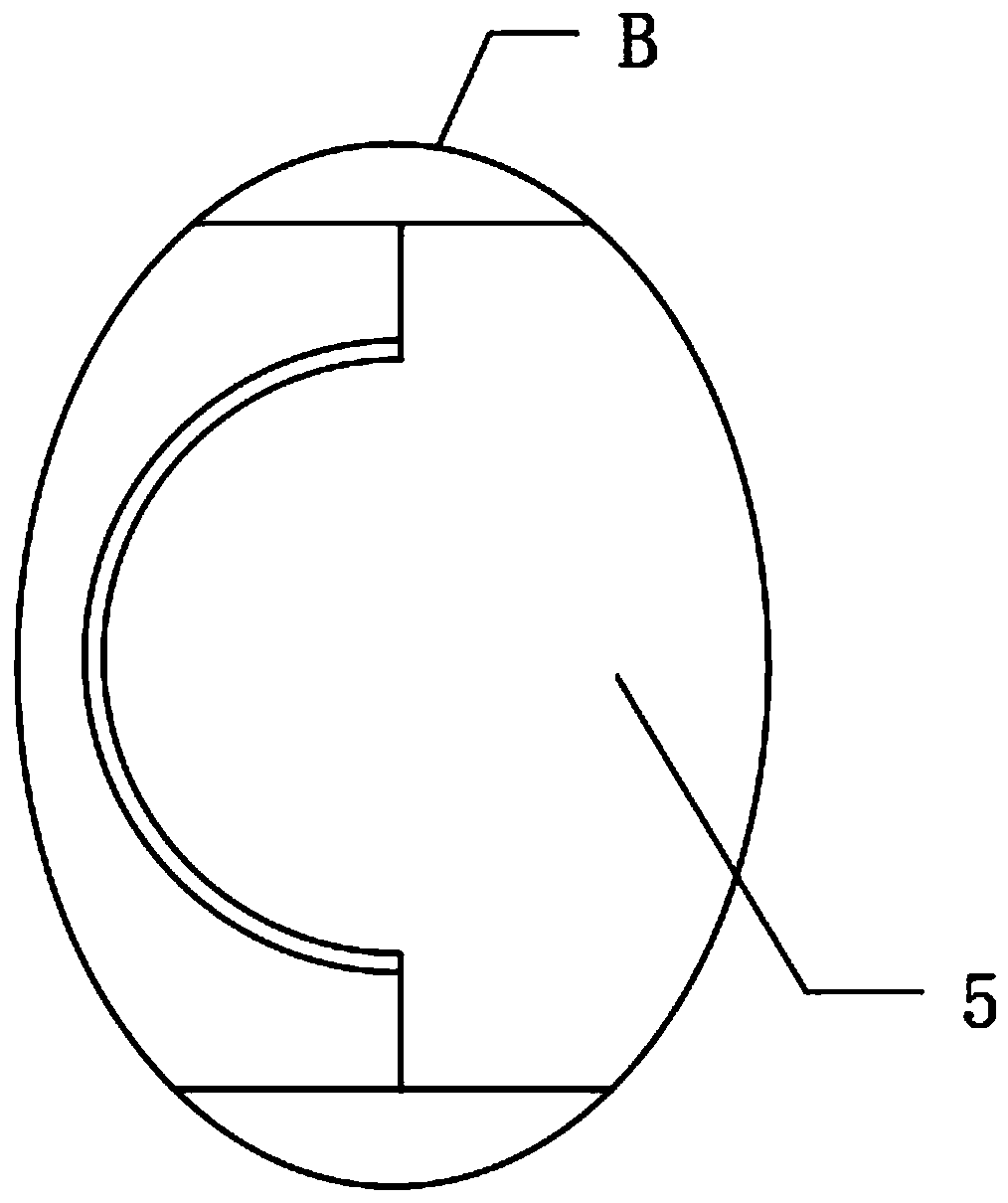

[0045] see Figure 1-5 , a new type of prefabricated wall-column connection structure, see figure 1 and Figure 4-5, including prefabricated side column 1 and prefabricated shear wall 2, the upper ends of prefabricated side column 1 and prefabricated shear wall 2 are fixedly connected with a plurality of anchors 17 (anchor 17 is a well-known technology well known to those skilled in the art, and its detailed structure is in This will not be described too much), and the anchors 17 are provided with shackles, the anchors 17 are convenient for hoisting equipment, and the prefabricated side columns 1 are provided with a plurality of positioning holes 16. The positioning holes 16 are convenient for the prefabricated side columns 1 to be installed accurately. For positioning, the side walls of the prefabricated side columns 1 and the prefabricated shear walls 2 are provided with a plurality of reserved holes 18 (the reserved holes 18 are well-known technologies well known to those...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com