Sideboard mold

A mold and side plate technology, applied in the field of side plate molds, can solve the problems of inability to pour in large quantities and inconvenient storage, and achieve the effects of large-scale production, simple structure, and low technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

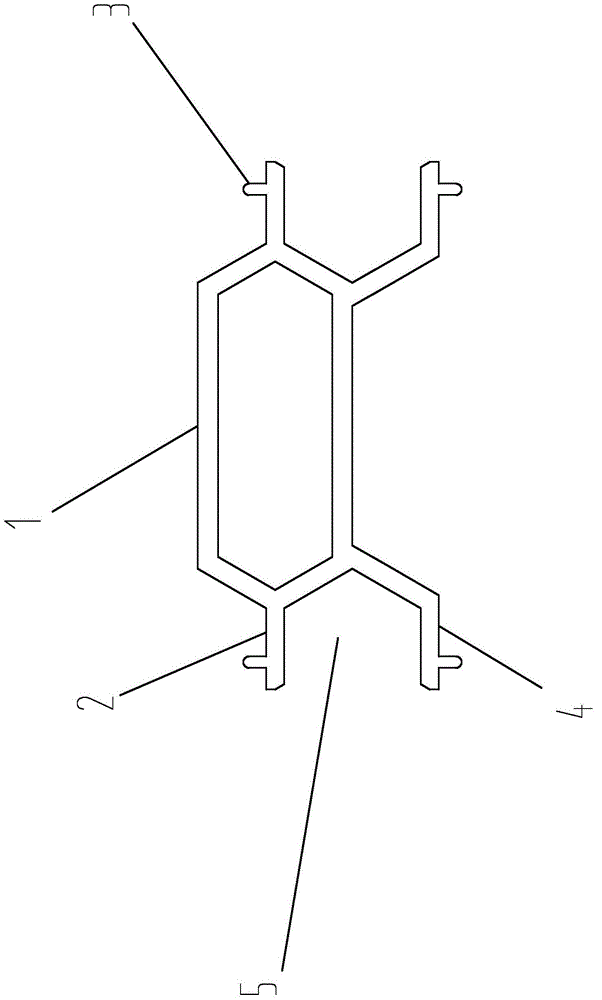

[0012] Such as figure 1 As shown, the present invention includes a hexagonal tube 1, and wings 2 are arranged on both sides of the hexagonal tube 1 diagonally outside, a reinforcing beam 3 is arranged on one side of the wing 2, and a reinforcing beam 3 is arranged on the lower side of the hexagonal tube 1. The lower wing 4 is provided with a reinforcing beam 3 under one side of the lower wing 4 , and the wing 2 and the lower wing 4 form a fixed chute 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com