High-temperature-resistant antibacterial nanofiber non-woven fabric and preparation method and application thereof

A technology of nanofibers and non-woven fabrics, which is applied in fiber processing, textiles and papermaking, and fiber chemical characteristics. Low temperature and other issues, to achieve the effect of blocking and adsorbing viruses and bacteria, light weight and high air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

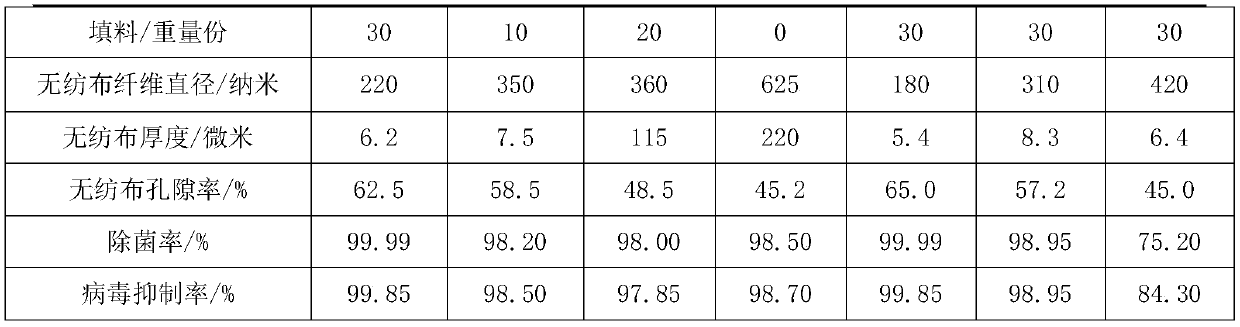

[0030] 1) Polybutene, nano-silver (bacteriostatic agent), tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antiaging agent 1), phosphorous acid tri( 2,4-di-tert-butylphenyl) ester (antiaging agent 2), stearic acid (antistatic agent), titanium oxide (coloring agent), sodium dodecylbenzenesulfonate (surfactant), calcium carbonate (filler) according to the prescription of table 1, blend in twin-screw extruder, granulate, make special material for non-woven fabric;

[0031] 2) Add the above-mentioned special material for non-woven fabrics into the barrel of the electrospinning equipment, control the temperature of the barrel to 200°C, set the distance between the two poles of the electrospinning equipment to 20cm, the applied voltage between the two poles to 60kV, and the spinning solution to advance at a speed of 200μL / h; the spinning environment temperature is 40°C, the spinning environment humidity is 40%, and the spinning time is 0.5h to obtai...

Embodiment 2

[0036] The polybutene / polypropylene inner alloy, Na 7 PMo 11 MnO 40 (antibacterial agent), octadecyl-3,5-bis(1,1-dimethylethyl)-4-hydroxyphenylpropionate (antiaging agent 1), tetrakis[β-(3,5- Di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antiaging agent 2), dodecyltrimethylammonium chloride (antistatic agent), methylene blue (dyeing agent), octadecyl Sodium sulfate (surfactant) and silicon dioxide (filler) are blended in a twin-screw extruder according to the formula in Table 1, and granulated to make special materials for non-woven fabrics.

[0037] Others are the same as embodiment 1. The prepared microfiber nonwovens were tested, and the results are listed in Table 1.

Embodiment 3

[0039] Except that the butene polymer used is a polybutene / polyethylene kettle alloy, and the spinning time is 4 hours, the others are the same as in Example 2.

[0040] The prepared microfiber nonwovens were tested, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com