Sulfur-fixing denitration coal-saving decoking coke inhibitor and preparation method thereof

A technology for denitrification and coal saving, applied in the field of coke removal and coking inhibitor, can solve the problems of narrowing of coal distribution channels, affecting gas flow, and increasing furnace outlet pressure, so as to reduce the residual carbon content of coal ash, reduce furnace temperature, and reduce The effect of cracking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

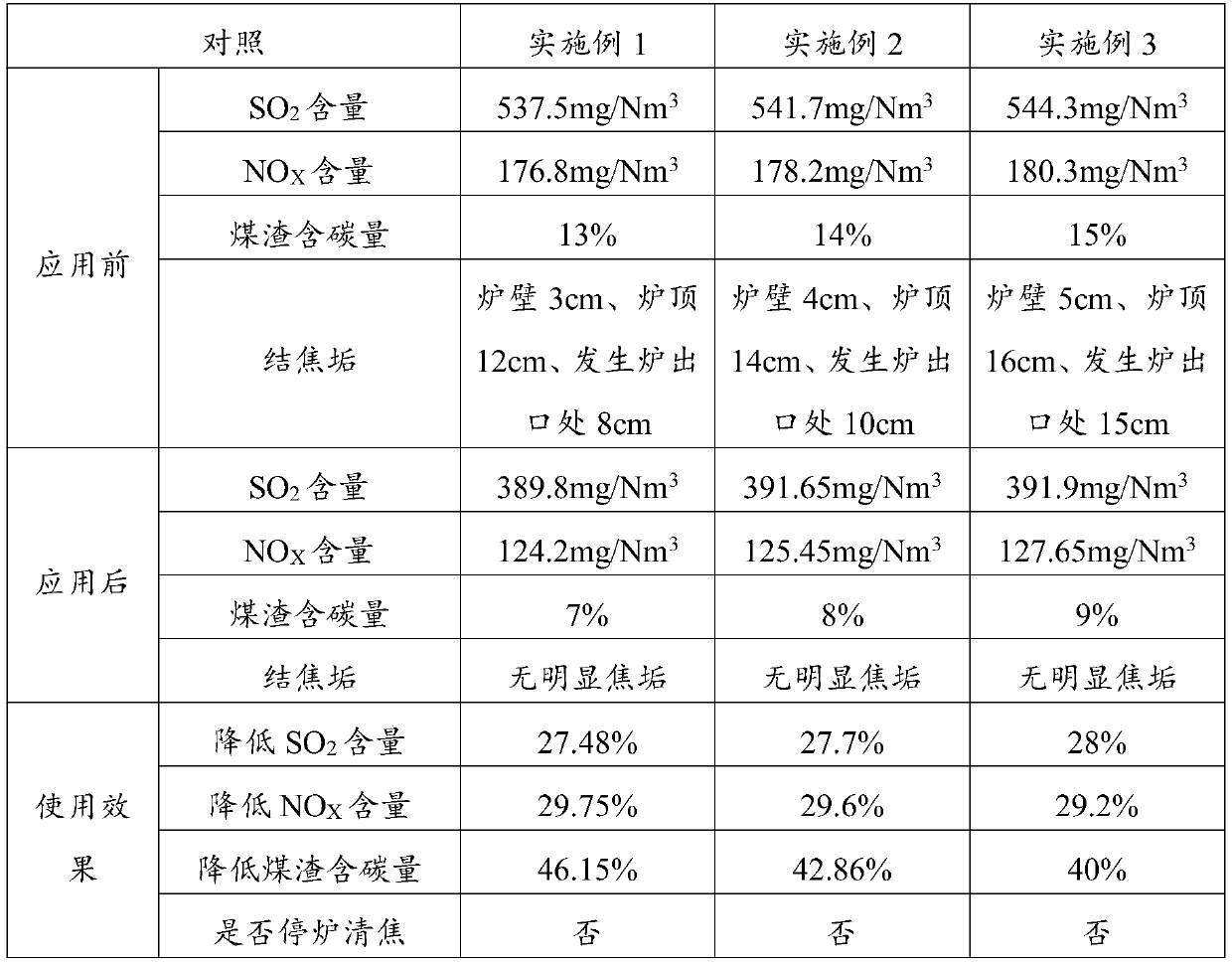

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing the sulfur-fixing, denitrification, coal-saving, coke-removing and coking-inhibiting agent, which comprises the following steps:

[0033] 1) mixing the auxiliary agent, polyethylene oxide, cobalt isooctanoate, zirconium isooctanoate, nickel isooctanoate and zinc isooctanoate to obtain the first mixture;

[0034] 2) mixing the first mixture, aluminum acetylacetonate and titanium dioxide to obtain the second mixture;

[0035] 3) Mix the second mixture with the surfactant to obtain the sulfur-fixing, denitrification, coal-removing, coke-removing and coking-inhibiting agent.

[0036] In the present invention, the mixing process of the auxiliary agent preferably first mixes 4-nitrophenol, phthalate, methyl alcohol, 2,6-di-tert-butyl-4-methylphenol and triethanolamine, and then Add polyethylene glycol monomethyl ether slowly, and the mixing time is preferably 20-40 minutes, more preferably 30 minutes.

[0037] In th...

Embodiment 1

[0051] After mixing 15 parts of 4-nitrophenol, 8 parts of phthalate, 2 parts of methanol, 0.3 part of 2,6-di-tert-butyl-4-methylphenol and 0.1 part of triethanolamine in a stirring tank , slowly add 18 parts of polyethylene glycol monomethyl ether and mix for 30 minutes, then add 2 parts of polyethylene oxide, 2 parts of cobalt isooctanoate, 1 part of zirconium isooctoate, 1 part of nickel isooctoate and 2 parts of zinc isooctanoate and stir the reaction 30 minutes, then add 2 parts of aluminum acetylacetonate and 2 parts of titanium dioxide and stir for 30 minutes, and finally add 20 parts of alkylphenol polyoxyethylene ether and 5 parts of fatty alcohol polyoxyethylene ether into the stirring tank and stir for 30 minutes to form a homogeneous liquid to obtain sulfur fixation Denitrification and coal decoking agent.

Embodiment 2

[0053] After mixing 18 parts of 4-nitrophenol, 10 parts of phthalates, 5 parts of methanol, 0.3 parts of 2,6-di-tert-butyl-4-methylphenol and 0.2 parts of triethanolamine in a stirring tank , slowly add 20 parts of polyethylene glycol monomethyl ether and mix for 30 minutes, then add 3 parts of polyethylene oxide, 2.5 parts of cobalt isooctanoate, 1 part of zirconium isooctanoate, 1 part of nickel isooctanoate, 3 parts of zinc isooctanoate and stir to react 30 minutes, then add 2.5 parts of aluminum acetylacetonate and 3 parts of titanium dioxide and stir for 30 minutes, and finally add 24 parts of alkylphenol polyoxyethylene ether and 6 parts of fatty alcohol polyoxyethylene ether into the stirring tank and stir for 30 minutes to form a homogeneous liquid to obtain sulfur fixation Denitrification and coal decoking agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com