Air insulating container material discharging mouth

A technology for isolating air and discharge nozzles, applied in the field of container lids, which can solve the problem of random air entering the container, and achieve the effects of simple structure, low production cost, and reduced oxidation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in conjunction with the accompanying drawings.

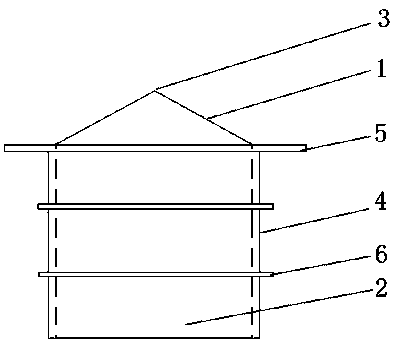

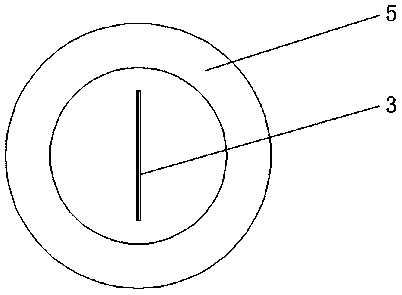

[0031] Such as figure 1 , 2 As shown, the air-isolated container discharge nozzle of the present invention includes a discharge nozzle 1 and a container mouth sealing body (sealing gasket plug). The lower part of the discharge nozzle 1 is bell-shaped, and the top 3 of the discharge nozzle is slit-shaped and made of flexible silicone material. The gasket plug includes a casing 4, a sealing layer 5, and a sealing ring 6. The center of the casing 4 is a discharge chamber 2, the top end is connected to the sealing layer 5, and two layers of sealing rings 6 are distributed around the periphery. The bottom of the discharge nozzle 1 is connected to the discharge cavity 2 of the gasket plug, and the top 3 of the discharge nozzle is higher than the sealing body of the container mouth. Under normal conditions, the top 3 of the discharge nozzle is in an automatic closing state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com