Spiral plate type bearing water tank

A technology of spiral plate type, pressurized water tank, which is applied in the field of pressurized water storage tanks, can solve the problems of water supply pump weight, large volume, increased energy consumption of water tank insulation, high power of water supply pump, etc., to save indoor installation space and reduce mixing speed , The effect of reducing the weight of the host

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

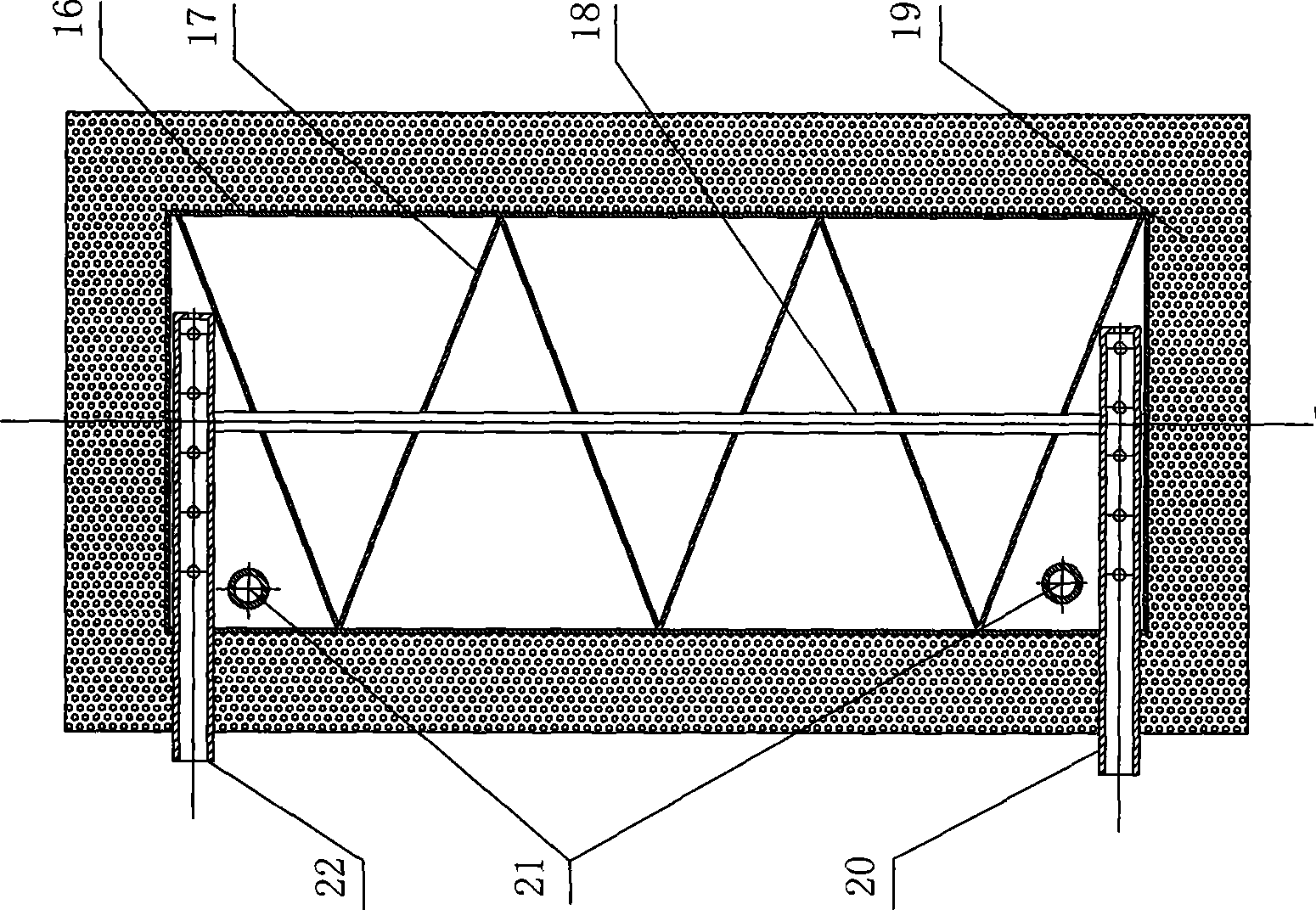

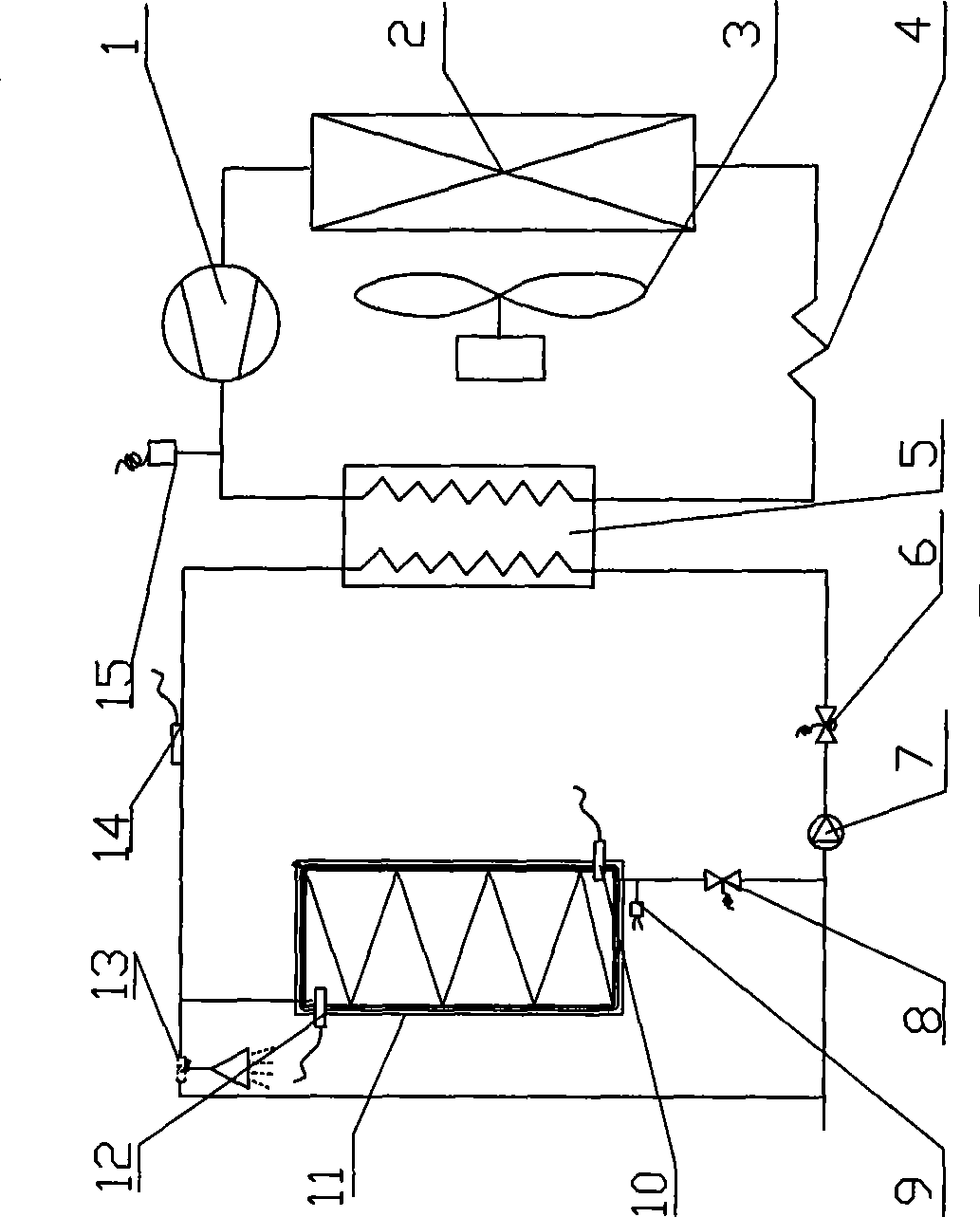

[0024] see figure 1 , figure 2 , the pressurized water tank liner 16 is set to be a cylinder with an insulating layer 19, in the pressurized water tank liner 16 of the cylinder, a deflector 17 is arranged spirally around the axis of the cylinder, and the cold water outlet is arranged at On the bottom side wall of the pressurized water tank liner 16, in the bottom layer of the deflector 17; Between the water outlet and the hot water port, a spiral water flow channel is formed along the deflector plate 17 .

[0025] In specific implementation, the corresponding structural settings also include:

[0026] In order to promote the uniform advancement of the water flow in the water flow channel, in the hot water port and the cold water port, a hot water pipe 22 and a cold water pipe 20 are inserted radially along the inner tank of the pressurized water tank, and along the axial direction of the hot water pipe 22 Water collection holes are distributed, and water distribution holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com