Ultralow-energy-consumption passive building vacuum insulation plate and rock wool composite wall and construction method thereof

A vacuum insulation panel and passive building technology, applied in the direction of insulation, construction, building components, etc., can solve the problem of reducing indoor use area, and achieve the effect of reducing the risk of fire, improving efficiency and good sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

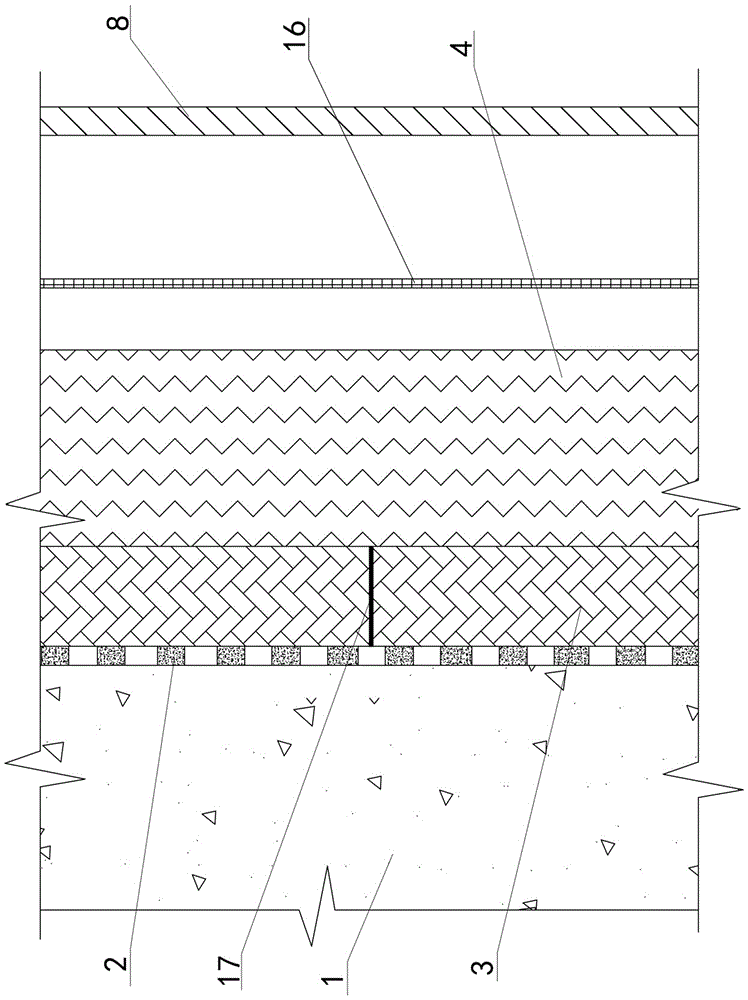

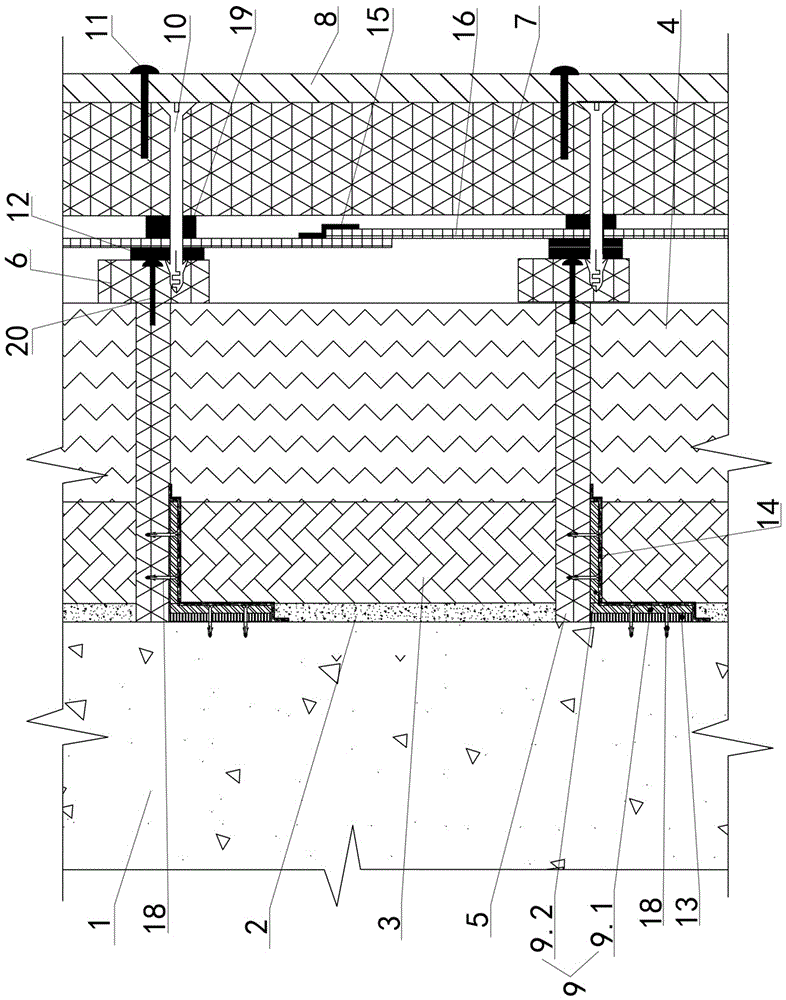

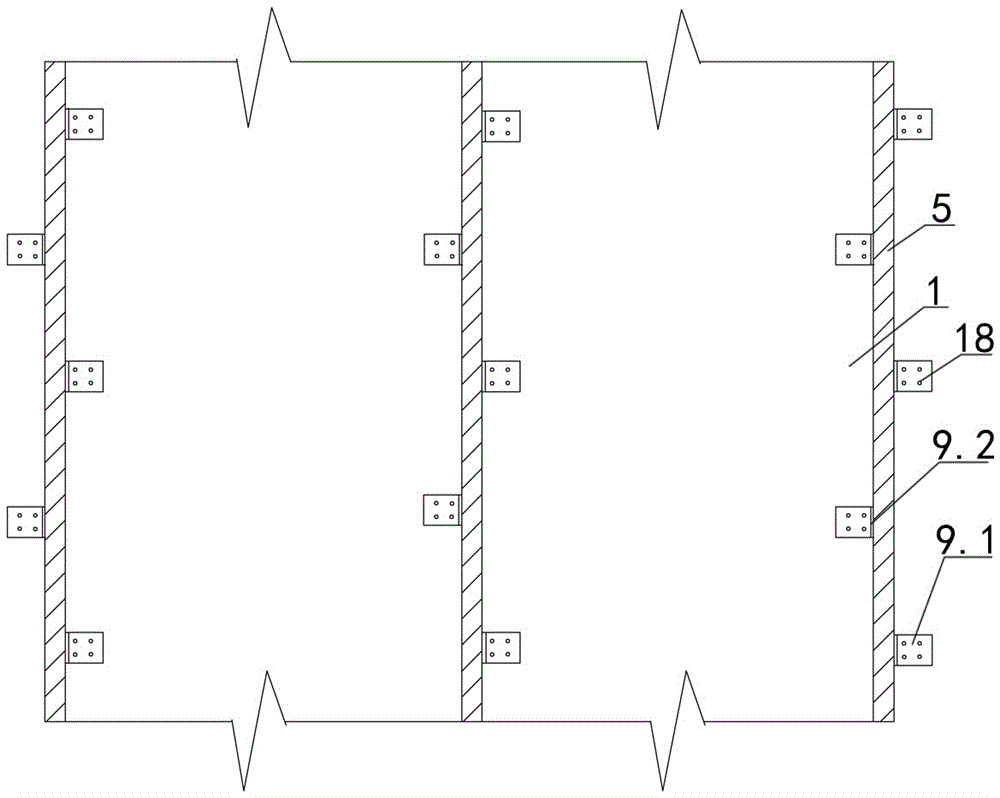

[0053] Examples see Figure 1-9 As shown, this ultra-low energy passive building vacuum insulation board and rock wool composite wall, including the bottom vertical keel 5, the composite insulation layer, and the end sealing plate keel 6, which are sequentially arranged from the inside to the outside from the base wall 1 , an airtight layer 16, an outer horizontal keel 7 and a decorative panel 8.

[0054] The keels in this embodiment are all wooden keels, which are economical and metal keels will form thermal bridges, so wooden keels are used. The thickness of the bottom vertical keel should be slightly greater than the sum of the thickness of the vacuum insulation board and the rock wool board, the width of the bottom vertical keel should be about 18mm, and the distance between the two bottom vertical keels should not be greater than 600mm. Top studs should extend from one wall to the other.

[0055] The bottom vertical keels 5 are vertically arranged in parallel and at int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com