Method for adding iron in titanium and titanium alloy ingots

A titanium alloy and ingot casting technology, which is applied in the field of titanium and titanium alloy preparation, can solve the problems of uneven mixing, increased operation difficulty, and difficult composition ratio, so as to improve distribution uniformity, reduce production cost, and implement difficulty small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for adding iron in titanium and titanium alloy ingots, the method for adding iron in the titanium and titanium alloy ingots comprises the following steps,

[0027] Step (a), this example material is the lower TC4 material head of iron content, and its forging machine adds φ 96mm round bar;

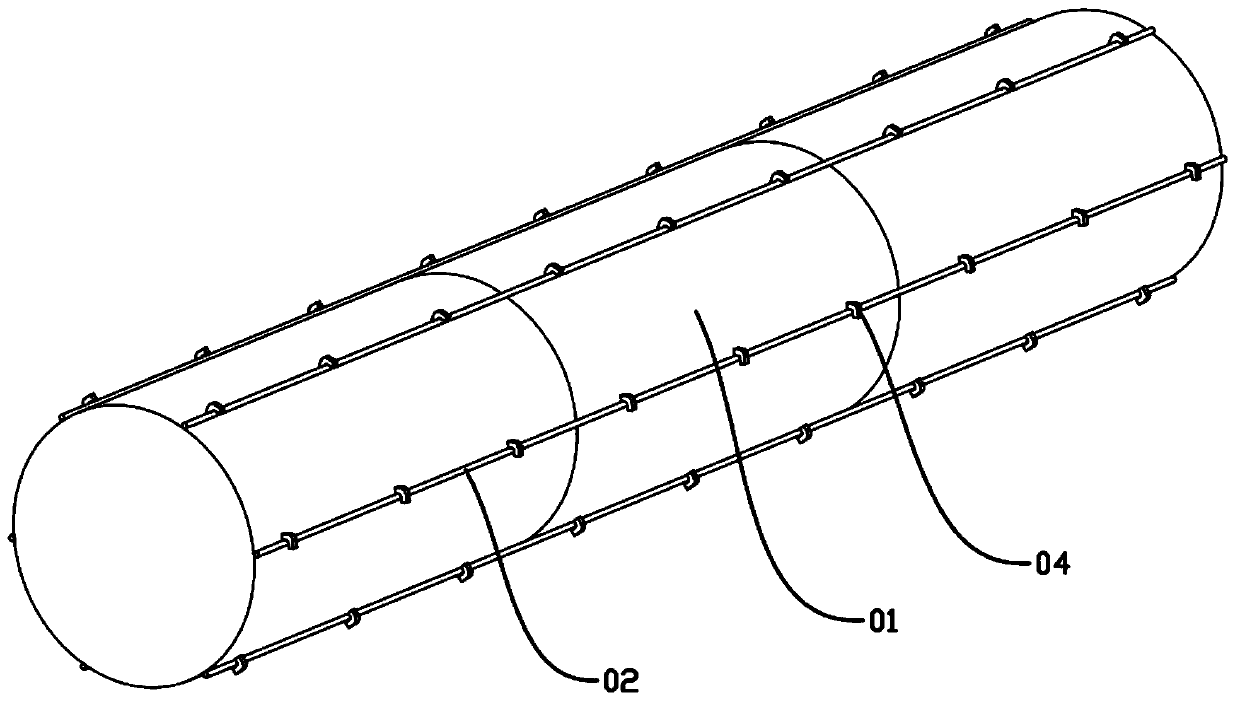

[0028] In step (b), the electrode blocks forged in step (a) are sequentially welded along the axial direction of the electrode blocks to form electrode rods;

[0029] Step (c), according to the target composition and the needs of reverse segregation cloth, calculate the amount of iron that needs to be added to the electrode, and select the specification and quantity of the iron wire 02 that needs to be added. The diameter of the iron wire 02 is not greater than 8.5mm, and the length is not greater than the total length of the electrode. In this embodiment, we choose three 14# iron wires 02, whose diameter is about 2mm;

[0030] In step (d), the electrode rod assembled and ...

Embodiment 2

[0034] A method for adding iron in titanium and titanium alloy ingots, the method for adding iron in the titanium and titanium alloy ingots comprises the following steps,

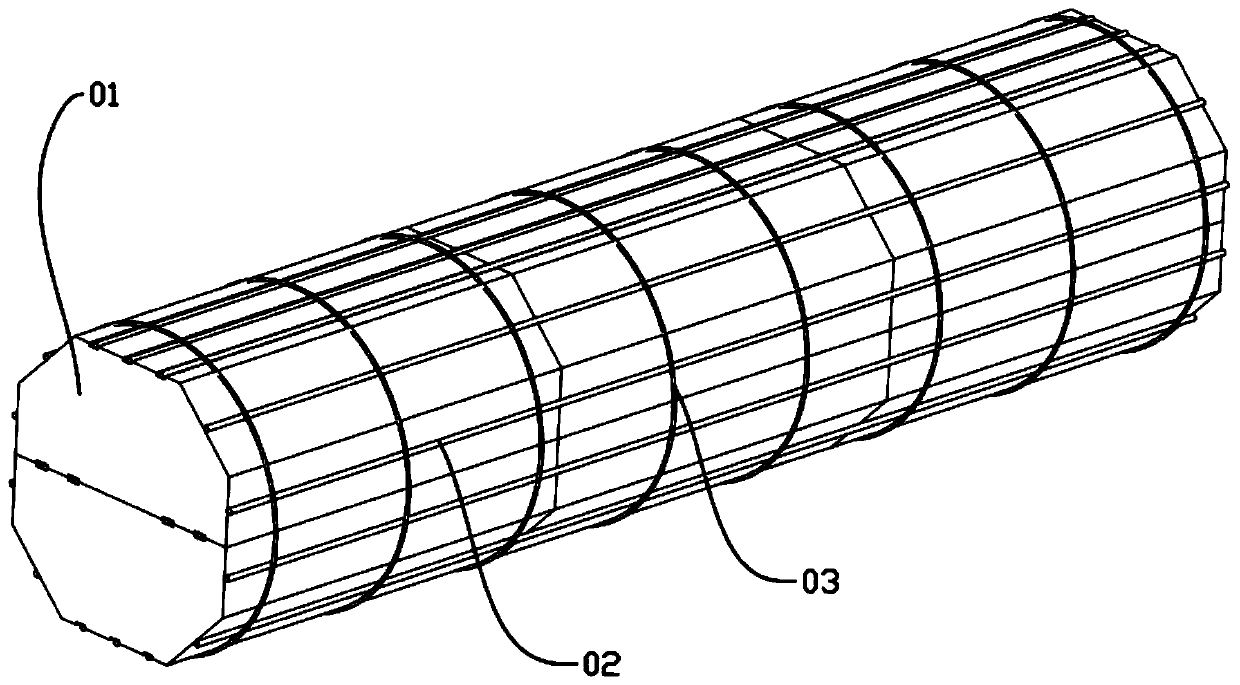

[0035] Step (a), the material of this embodiment is a number of low-iron TC4 rods with similar components, which are forged into square rods with a size of 150×150×Lmm, and subjected to surface treatment to obtain electrode block 01;

[0036] Step (b), combining the electrode block 01 obtained in step (1) into an electrode with a specification of 150×300×Lmm and welding it;

[0037] Step (c), according to the target composition and the needs of reverse segregation cloth, calculate the amount of iron that needs to be added to each electrode, and select the specification and quantity of iron wire 02 that needs to be added. The diameter of iron wire 02 is not greater than 8.5mm, and the length is not greater than the total electrode Length, in the present embodiment, we select 3 10# iron wires 02 for use, and ...

Embodiment 3

[0043] A method for adding iron in titanium and titanium alloy ingots, the method for adding iron in the titanium and titanium alloy ingots comprises the following steps,

[0044]Step (1), first calculate the content of sponge titanium, aluminum vanadium alloy, aluminum beans and titanium dioxide in the electrode block according to the content of other elements except iron in the electrode block to be prepared, and weigh the sponge titanium, aluminum Mix the vanadium alloy, aluminum beans and titanium dioxide evenly, then add the mixed materials into the mold and weigh them, then mix the cloth normally. ;

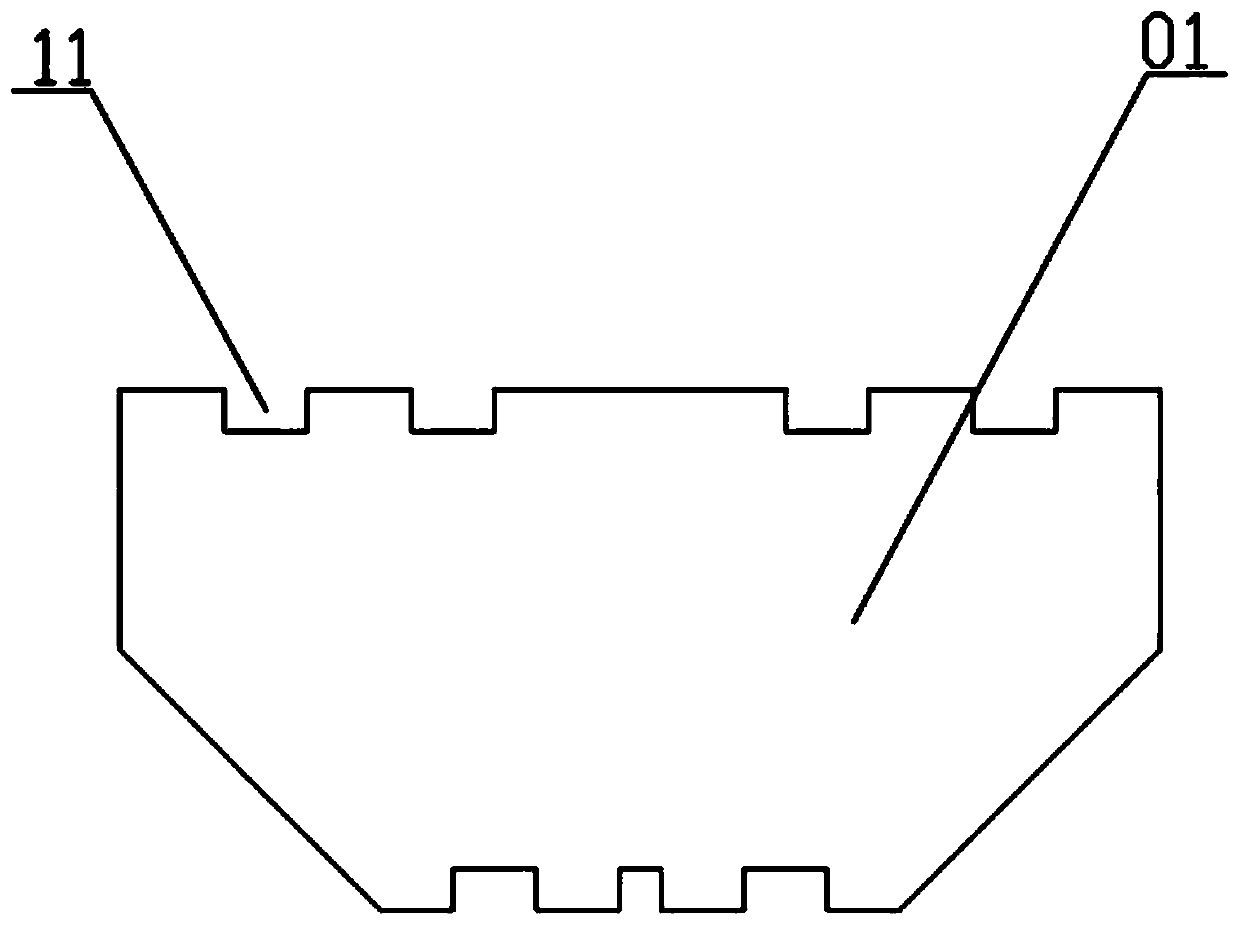

[0045] In step (2), use the stamping head of the punching machine to squeeze the mold cavity, thereby completing the pressing of the electrode block 01. In order to fix the iron wire added later, a non-essential measure that can be taken is to make the upper and lower surfaces of the electrode block 01 along the electrode block 01 A groove 11 is formed in the axial directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com