Forming preparation method of degradable nitrile rubber gloves

A technology of nitrile rubber and nitrile latex, which is applied in the direction of gloves, clothing, applications, etc., can solve the problems of low utilization value, limited scope of application, violation, etc., to improve strength and mechanical properties, improve rheological properties, and improve processing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

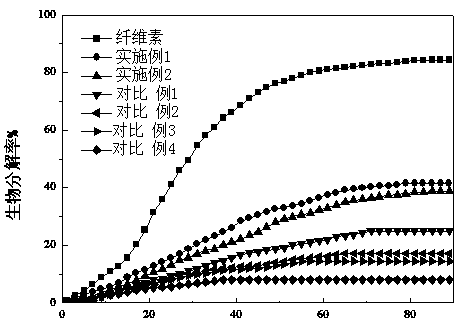

Examples

Embodiment 1

[0029] The first step, prepare cyanoacrylate mixed and liquid impregnation latex: by weight, first according to the composition of nitrile latex: 76 parts of carboxylated nitrile latex, 0.2 part of potassium hydroxide, 15 parts of modified geopolymer 0.1 part, 0.1 part of initiator azobisisobutylamidine hydrochloride, beating and mixing evenly to obtain impregnated emulsion, and then according to the composition of cyanoacrylate mixed solution: 33 parts of hexyl cyanoacrylate, 0.3 parts of buffer copper acetate 34 parts of liquid nitrile rubber, 5 parts of thickener PF, 0.1 part of stabilizer propane sultone, 5 parts of softener dipropylene phthalate, 2 parts of accelerator zinc dimethyl dithiocarbamate, Mix evenly to obtain a mixed liquid of hexyl cyanoacrylate, which is dipped into latex liquid and sent into the latex dipping tank, and the mixed liquid of hexyl cyanoacrylate is sent into the polyethylene pre-soaking tank; the second step, the dipping molding of gloves: use S...

Embodiment 2

[0031] (1) Preparation of dipping latex and cyanoacrylate mixed solution: in parts by weight, first according to the composition of nitrile latex: initiator cumene hydroperoxide 0.02 parts, modified geopolymer 13 parts, carboxyl 64 parts of nitrile latex, 0.1 part of potassium hydroxide, beating and mixing evenly to obtain impregnated latex liquid, and then according to the composition of cyanoacrylate mixed liquid: stabilizer 2,6-di-tert-butyl-4-methylphenol 0.05 0.01 part of buffering agent citric acid, 3 parts of softener tricresyl phosphate, 0.1 part of accelerator CA, 25 parts of heptyl cyanoacrylate, 31 parts of liquid nitrile rubber, 5 parts of thickener zinc methacrylate , mixed evenly to obtain a mixed solution of heptyl cyanoacrylate, which was impregnated with latex and sent into a latex dipping tank, and the mixed solution of heptyl cyanoacrylate was sent into a polyethylene pre-preg tank; (2) Glove dip molding: use Spray the hand mold with hot water at 75°C, clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com